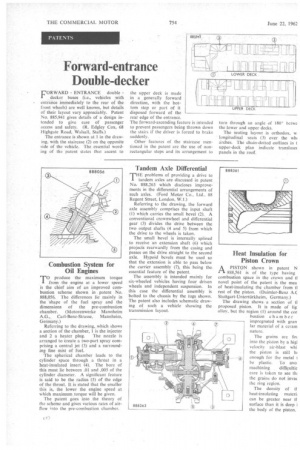

Forward-entrance Double-decker

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

FORWARD ENTRANCE double decker buses (i.e., vehicles with entrance immediately to the rear of the front wheels) are well known, but details of their layout vary appreciably. Patent No. 885,941 gives details of a design intended to give ease of passenger access and safety. (R, Edgley Cox, 68 Highgate Road, Walsall, Staffs.) The entrance is shown at 1 in the drawing, with the staircase (2) on the opposite side of the vehicle. The essential wording of the patent states that ascent to TO produce the maximum torque from the engine at a lower speed is the chief aim of an improved combustion scheme shown in patent No. 888,056. The differences lie mainly in the shape of the fuel spray and the dimensions of the pre-combustion chamber. (Motorenwerke Mannheim A.G., Carl-Benz-Strasse, Mannheim, Germany.)

Referring to the drawing, which shows a section of the chamber, 1 is the injector and 2 a heater plug. The nozzle is arranged to create a two-part spray comprising a central jet (3) and a surrounding fine mist of fuel.

The spherical chamber leads to the cylinder space through a throat in a heat-insulated insert (4). The bore of this must lie between .01 and .005 of the cylinder diameter. A significant feature is said to be the radius (5) of the edge of the throat. It is stated that the smaller this is, the lower the engine speed at which maximum torque will be given. The patent goes into the theory of the scheme and gives various rates of airflow into the pre-combustion chamber. the upper deck is made in a generally forward direction, with the bottom step or part of it disposed forward of the rear edge of the entrance. The forward-ascending feature is intended to prevent passengers being thrown down the stairs if the driver is forced to brake suddenly.

Other features of the staircase mentioned in the patent are the use of nonrectangular steps and its arrangement to

Tandem Axle Differential

THEproblems of providing a drive to tandem axles are discussed in patent No. 888,263 which discloses improvements in the differential arrangements of such axles. (Ford Motor Co.. Ltd., 88 Regent Street, London, W.1.) Referring to the drawing, the forward axle assembly comprises the input shaft (1) which carries the small bevel (2). A conventional crownwheel and differential gear (3) divides the drive between the two output shafts (4 and 5) from which the drive to the wheels is taken.

The small bevel is internally splined to receive an extension shaft (6) which projects rearwardly from the casing and passes on the drive straight to the second axle. Hypoid bevels must be used so that the extension is able to pass below the carrier assembly (7), this being the essential feature of the patent. The assembly is intended mainly for six-wheeled vehicles having four driven wheels and independent suspension. In this case the differential assembly is bolted to the chassis by the lugs shown. The patent also includes schematic drawing of such a vehicle showing the transmission layout. turn through an angle of 1800 bctwe the lower and upper decks.

The seating layout is orthodox, w longitudinal seats (3) over the will arches. The chain-dotted outlines in t upper-deck plan indicate transluscc panels in the roof.

PAA PISTON shown in patent N 888,561 is of the type having combustion space in the crown and ti novel point of the patent is the mea of heat-insulating the chamber from ti rest of the piston. (Daimler-Benz A.( Stuttgart-Untertfirkheim, Germany.) The drawing shows, a section of tl proposed. piston. It is made of hg alloy, but the region (1) around the cor bastion chamber impregnated with gran Jar material of a ceram nature.

The grains are fin into the piston by a higl velocity air-blast whi the piston is still hi enough for the metal I be plastic. To avo machining . difficultic care is taken to see th. thc grains do not invm the ring region.

The density of a heat-insulating mated can be greater near It surface than it is deep the body of the piston.