THE ' rapidly increasing popularity of high-capacity semi-trailers with twin-oscillating axles

Page 46

Page 47

Page 48

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

is reflected by the growing number of manufacturers who are currently offering designs of this type. Among the

advantages of this class of semi-trailer can be listed reduced tyre wear and lower unladen weight when compared with tandem-axle models of equivalent payload capacity. A recent introduction to this field is the Scammell Fourtrak 15-tonner, which has an unladen weight of under three tons, a braking frictional area of 504 sq. in., pressed-steel framing members and a suspension system which provides good articulation whilst eliminating the need for lubrication.

Officially announced in September of last year, and exhibited in public for the first time at the Scottish Motor Show two months later, the Fourtrak is now in full produc tion following extensive development work in connection with the suspension. Although having only recently joined this market, Scammell Lorries, Ltd. were one of the earliest manufacturers to investigate the possibilities of this type of wheel configuration, a patent—No. 283,276—having been taken out by the company as long ago as 1926, though there is no record of a prototype having been built to a patent specification.

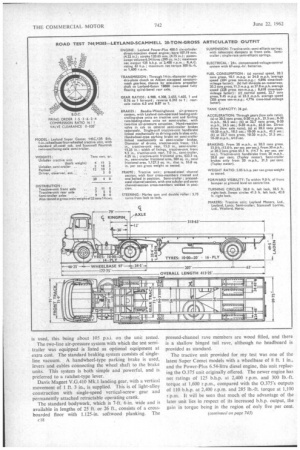

Because the Fourtrak has been designed with a 15-ton payload in mind, it was unfortunate in a way that the semi

trailer made available to me for test recently was offered in conjunction with a Leyland Super Comet tractive unit, the manufacturer's gross-train-weight limitation of which is 20 tans. As it was, the kerb weight of the unladen combination totalled 7 tons 10.25 cwt., so a payload of only 12.5 tons could be carried within the 20-ton limit, and most of my road test was conducted at this weight.

The figures obtained with this reduced payload indicated a reasonable road performance, the outfit not being outstanding in any particular respect but nevertheless proving c 16

to be quite a good all-rounder. Driving the Super Comet at 20 tons gross, it was easy to appreciate the wisdom of Leyland Motors, Ltd., in restricting this tractive unit to that weight figure: there was no excessive power at 20 tons, and subsequent figures taken with the outfit grossing 22 tons 14 cwt. (a full 15-ton payload) showed the Super Comet to be pushed almost to the limit. Leyland's will, I feel sure, strongly endorse my warning that this tractive unit should not be worked at over 20 tons.

An indication of how the comparatively low power-toweight ratio affects the performance can be seen from the first two sets of fuel-consumption figures quoted in the data panel: tested over an undulating main road with a fair amount of traffic and several major intersections, the Super Comet returned 10.1 m.p.g. at an average speed of 24.0 m.p.h., the optional sixth overdrive ratio with which the tractive unit was equipped being in use for only half the total running time of 30 minutes over the 12-mile course employed.

Under full-throttle conditions on a 23-mile stretch of the M1 motorway, however, a consumption rate of 11.3 m.p.g. was recorded at an average speed of 37.8 m.p.h., overdrive having been usable for nearly all of the distance, although on three occasions the low ratio of the two-speed axle (another production option) was in use on gradients for about a minute in each case. Comparison of these figures does prove that the gradients of a normal British trunk road demand such continuous use of the gearbox intermediate ratios that fuel economy suffers as a result.

Pressed-steel channel-section side-members, 0.3125-in. thick, form the basis of the Fourtrak semi-trailer, these having a maximum depth of 15 in., with 3.5-in.-wide flanges. Towards the front, the side-members are reduced in depth by about a half, and the fifth-wheel coupling upper plate, which carries an S.M.M.T. 2-in, kingpin, is welded directly to the members, with several transverse and longitudinal local members immediately above the plate to provide rigidity at this potential weak spot. Alternative to the fifth-wheel kingpin equipment, Scammell M.H. automatic gear can be supplied.

Cross-members of tubular and channel section are welded between the side-members and, in addition to full-width members at front and rear, at each sidethere are eight channel-section outriggers welded between the side-members and the 6-in.-deep pressed-steel siderave channels. Additional longitudinal bracing is provided by a 5 in. x 2.5 in. X 0.1875 in. pressed channel running down the centre of the frame and extending from the rear of the kingpin plate to the rearmost cross-member. The whole frame assembly presents a very robust, well-designed appearance promising an extensive trouble-free life.

The rear suspension is carried on the ends of vertical pressed-steel channels which butt against the lower flanges of the main side-members and which are triangularly braced against sideways movement by rolled-steel channels which bear against the cross-members immediately ahead of and behind the wheel centre-line, and against longitudinal movement by angle-iron bracing members. At the foot of.each of the vertical channels there are cast brackets which contain hemispherical cups: these cups form the bearing surfaces against which the springs act.

The cups are lined with Railko asbestos-based resinbonded anti-friction plastics mouldings, and into these fit

By JOHN F

A.M.I.R

chromium-plated hemispheres, the flat lower faces of which carry squared pegs. These pegs fit into slots in the ends of the spring main leaves, so permitting longitudinal movement of the spring ends when deflection takes place. The cup-and-ball assemblies, with the " anti-friction plastics mouldings between them, are kept in contact by light springs which are bolted to the turned-down ends of the main leaves and which bear against through-bolts joining the extended arms of the cup brackets.

Angular deflection at the cup-and-ball joints is sufficient to permit 5.5 in. vertical movement of either outer wheel and. 5 in. vertical movement of either inner wheel, whilst the action of the joints also ensures full bearing contact during extreme spring-deflection conditions. The use of the plastics cup linings, of course, eliminates the need for lubrication at these points whilst, because there is only very small movement between the lower faces of the hemispheres and the upper faces of the main leaves, no need for lubrication at these points has been found either.

. MOON,

.T.E.

Because both ends of each spring are free to slide longitudinally, some form of positive axle location has had to be provided. There is a single radius arm, therefore, joining the front of each axle to the back of the mounting channel on each side, and these arms are rubber bushed, again to eliminate the need for lubrication. A subsidiary result of all the lubrication-free bearings employed in • this suspension is that the noiSe factor will be reduced also.

The axles have eight-stud hubs and the standard tyre equipment is 10.00-20 (16-ply). Girling 15.25 x 4.25 twoleading-shoe brakes are employed, and each pair is actuated through a direct mechanical linkage by a BendixWestinghouse diaphragm-type unit mounted on each axle between the wheels. The maximum operating pressure of these diaphragm units is 60 p.s.i. on the footbrake circuit, but the air-pressure system is such that maximum reservoir pressure is fed to the actuators when the hand-reaction valve is used, this being about 105 p.s.i. on the unit tested.

The two-line air-pressure system with which the test semitrailer was equipped is listed as optional equipment at extra cost. The standard braking system consists of singleline vacuum. A handwheel-type parking brake is used, levers and cables connecting the wheel shaft to the brake units. This system is both simple and powerful, and is preferred to a ratchet-type lever.

Davis Magnet V.G.410 Mk.1 landing gear, with a vertical movement of 1 ft. 3 in., is supplied. This is of light-alloy construction with single-speed vertical-screw gear and permanently attached retractable operating crank.

The standard bodywork, which is 7-ft. 6-in, wide and is available in lengths of 25 ft. or 26 ft., consists of a crossboarded floor with L125-in. softwood planking. The pressed-channel rave members are wood filled, and there is a shallow hinged tail rave, although no headboard is provided as standard.

The tractive unit provided for my test was one of the latest Super Comet models with a wheelbase of 8 ft. 1 in., and the Power-Plus 6..54-litre diesel engine, this unit replacing the 0.375 unit originally offered. The newer engine has net ratings of 125 b.h.p. at 2,400 r.p.m. and 300 lb.-ft. torque at 1,600 r.p.m., compared with the 0.375's outputs of 110 b.h.p. at 2,400 r.p.m. and 285 lb.-ft. torque at 1,100 r.p.m. It will be seen that much of the advantage of the later unit lies in respect of its increased b.h.p. output, the gain in torque being in the region of only live per cent.

whilst the torque peak occurs '500 r.p.m. higher up the engine speed range. This demands increased use of the gears in order to maintain a reasonably high average speed.

The optional overdrive ratio was fitted to the standard five-speed constant-mesh gearbox of the Super Comet tested, and the rear axle was a two-speed unit consisting of an Eaton 18800 driving head carried in a Leyland case. This axle has an electric change-speed unit, and the ratios offered are 4.5 and 6.14, 5.14 and 7.02, 5.57 and 7.6, and 6.5 and 8.87 to 1, the test tractive unit having the lowest available set of ratios. From the performance of the outfit it seemed clear to me that any of the other ratios would have been too high for normal operation at 20 tons gross.

Alternative to the two-speed axle is the standard singlespeed doUble-reduction axle, offered with ratios of 5.044, 5.555, 6.25, 6.933, 7.428 and 7A2 to 1. It is possible that performance at 20 tons could be improved by use of one of the lower single-speed axles, although this would, of course, increase the gaps in the overall gearing and.so make the transmission less suitable for use behind the 400 engine, with its high-speed torque peak.

In other respects the Super Comet was perfectly standard arid had the normal10.00-20, (14-ply) tyres, alternative to which are 11.00-20 (12-ply) equipment or, on tractive units "-Only, 9.00.-20 (12-ply) or .(14-ply).Tractive-unit Super Comets have 36-gal. fuel tanks, as opposed to the 24-gal. tanksof the longer wheelbase versions. The standard all:teel cab was fitted, this being common. to Comet models allo and being basiCally similar to the cab employed on Leyland Beaver.. Hippo and Octopus models (also Albion vehicles) except for the absence of easy-access steps low down ahead of the front wheels, access to the cab of the Super Comet being through a rather small door over the cab wings. Extras in the cab of the test vehicle included heating and demisting equipment and a radio,

I was a bit disappointed with the braking figures obtained from 20 m.p.h. and 30 m.p.h. on a dry road, but as it was clear that the driving and semi-trailer wheels were tending to lock it is obvious that increasing the line pressure to above the present figure of 60 p.s.i. would not have reduced the stopping distance, so the somewhat long distances measured can only be put down to slight delay in the system.. Had the front brakes been doing more work, hOwever, slightly better results might have been obtained.

Semi-trailer braking performance recorded by the Tapley meter was commendably high, whilst I was pleased also with the maximum retardations, obtained. from' 20 m.p.h. by use of the tractive-unit handbrake by itself, this brake being of the single-pull, unassisted type: • • During the second day of the test, while a ftill 15-ton payload was being carried, further braking tests were conducted, using the meter to record maximum efficiencies. These showed that the footbrake efficiency had been reduced from just over 60 per cent. to 50 per cent. by the addition of the extra load, whilst the tractive unit handbrake performance fell from 20 per cent. to 14 per cent. The semi-trailer brakes were not so adversely affected. however, the efficiency at the higher weight being 28 per cent.

The data-panel figures show how the acceleration performances compare at the two weights: the acceleration rates recorded at 20 tons gross were reasonably good, but the additional 2.5 tons affected the times between 20 m.p.h. and 30 m.p.h. quite appreciably, and slow acceleration in this speed range can make a commercial vehicle sluggish to handle and render it difficult to keep pace with accompanying traffic, let alone overtake such traffic.

Gradient performance tests were made at 20 tons gross. Bison Hill being used: this has an average gradient of 1 in 10.5 and is 0.75. miles long; A full throttle climb in an ambient temperature of 19°C. (66°F.) was made in the rather leisurely time of 6.75 minutes, during which period the engine-coolant temperature rose from 69°C. (156'F.) to 86'C. (187°F.)—a fairly high final temperature. The lowest ratio used while climbing was bottom-high, this having been engaged for 2.5 minutes; the minimum speed

at this stage being 2 m.p.h. .

By coasting the outfit down this hill in neutral at 20 m.p.h. —a test lasting 2.5 minutes—fade resistance was shown to be really first class, a maximum' efficiency of 61 per cent. being obtained at the bottom of the hill.

Restart tests were conducted on the 1-in-6.5 section of the hill. The semi-trailer brakes were powerful enough to hold the outfit on this slope comfortably, and the.tractiveunit handbrake just managed to stop the vehicle rolling backwards: Bottom-low was needed for the restart, and it was obvious that there was not a lot of power to spare, although the vehicle moved away smoothly. Facing down the hill both sets of brakes held the vehicle safely, but a reverse-low restart was only just successful, reverse ratio being higher than bottom.

From the driver's angle the Super Comet artic. is quite a fair vehicle to work in. Although engine noise is somewhat excessive when accelerating hard through the gears, it is not too bad when cruising at a steady speed, and even at full throttle on. M l at a speed of over 45 m.p.h. it was possible to hear the radio without the volume having to be so loud as to cause distortion.

Stable and Comfortable Despite its short wheelbase, the tractive unit rode quite well when laden, and felt comfortably stable, with no indication of " tugging " at the coupling and no fear of the semi-trailer taking charge. The large steering wheel reqUires an appreciable number of turns from full lock to full -lock, and this causes the Super Comet to be a bit of a handful when reversing, although the steering characteristics are quite pleasant when travelling normally. A satisfactory amount of castor action is present without the required effort being too high.

For an air-pressure braking system the brake pedal effort needed is a bit on the high side, although the artificial reaction at the pedal will reduce the risk of over-zealous use of the brakes when running empty. The gear-changing actions were found to be good—both on the main gearbox and on the axle. Generally the range of vision available to the driver was found to be quite good, although the rather small mirrors came to me as something of a surprise on a modern British heavy-goods vehicle.