The Swiftsure Live! Jp to its Name

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Latest Thornycroft 6-tonner Puts up Lively Performance During Road Test: New Oil Engine Develops 80 b.h.p. at 2,600 r.p.in.

By John F. Moon, A.M.LR.T.E. WHEN the Thornycroft Swiftsure 6-ton chassis was introduced at the Scottish Show last November, it attracted much interest by reason of its all-plastics lightweight cab and high-speed sixcylindered oil engine, governed at 2,600 r.p.m. Other features noted by operators were the flat-top frame, making for simplified body construction, and the clean, simple and straightforward overall chassis design.

Production has now started at the Basingstoke works of Transport Equipment (Thornycroft), Ltd., and I was offered one of the initial batch for a two-day road test. Low chassis weight has made this vehicle a genuine under-3-ton, 30 m.p.h. model, and with a maximum recommended gross weight of 91 tons, payloads in excess of 6 tons may be carried without fear of overloading.

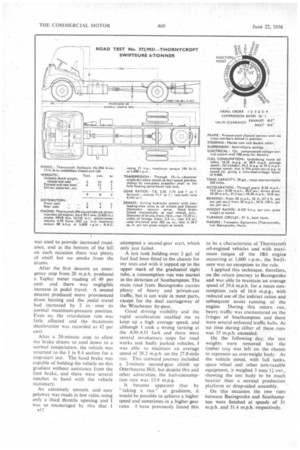

16.25 m.p.g. at 283 m.p.h.

When running at a gross weight of 2.; cwt. in excess of the recommended maximum, the Swiftsure was able to return 16.25 m.p.g. and the extremely high average speed of 28.9 m.p.h. over a 55.6-mile return run between Basingstoke and Southampton. The new power unit, therefore, allows prolonged high average speeds to be maintained without excessive fuel consumption, at the same time giving ample power for rapid acceleration and confident hill performance.

The new engine, known as the 1126, is a conventional six-cylindered direct-injection unit. Timing gears, as opposed to a chain, are used throughout and, with the exception of the steel timing wheel on the crankshaft, all gears and idlers are machined from wrought aluminium alloy with the object of giving quietness and longevity. The sevenbearing nitrided crankshaft carries a viscous fluid torsional vibration absorber, to which must be attributed the noticeably smooth running of the engine.

Free from Vibration

The centre bearing of the twopiece propeller shaft is suspended from twin rubber-bushed links, which ensure a vibrationless drive to the rear axle. The axle has spiralbevel final-drive gearing, and in addition to the standard ratio of 6.143 to 1, an alternative ratio of 7 to 1 can be offered when the vehicle is to be used in hilly areas.

Although of light section. the chassis-frame main members have a maximum depth of 9,A in., which is maintained for the length of the

a10

frame between the axles. The frame design is such as to ensure sufficient rigidity under normal conditions, with a limited amount of flexing on rough ground, and its high line and level upper flange should dispense with the need for longitudinal body runners and allow light underframing to be used.

Other standard features, of the design include a transverse exhaust system located immediately below the rear of the cab. This feature enables the production chassis to be used for spirit tankers without modi fication. A point which will be appreciated by operators is the provision of dual radiator caps—one inside and one outside the cab. This should satisfy both schools of thought as to where the filler should be.

The test chassis was a 13-ft. 6-in.wheelbase model with right-hand drive and standard all-steel cab. Variations on the standard specification included an 11-ft.-wheelbase model, part-plastics cab, and an Eaton 16,500 two-speed rear axle. The payload, which consisted of concrete blocks, was firmly mounted to the chassis frame by means of a substantial timber tray.

As it had already covered 470 miles, I considered the chassis to be reasonably well bedded-in and at once took it to the Basingstoke by-pass for acceleration and braking trials.

After repeated emergency stops from 20 m.p.h. and 30 m.p.h., I discovered that it was necessary to make an extremely quick, highpressure stab at the brake pedal to obtain optimum efficiency. My initial attempts, for example, produced a braking figure of 34 ft. from 20 m.p.h. and 70 ft. from 30 m.p.h., but as I became used to the characteristics of the system I was able to reduce these distances to 25 ft. and 54 ft., respectively.

This feeling of delayed action was even more marked when braking normally, but although rather disturbing at first, a driver new to the vehicle would quickly become accustomed to the reaction rate and long pedal travel, and adjust his 'braking style accordingly.

During these tests I set the Tapley meter to discover the maximum retardation rate. From 20 m.p.h. this was recorded as 0.93g., compared with an average retardation rate of 0.535g., whilst from 30 m.p.h., the meter recorded 1.Ig., compared with the average figure of 0.545g. The hand brake proved its usefulness by creating readings of 0.28g. on the Tapley meter when applied by itself from 20 m.p.h.

Acceleration times recorded in the data panel show that when starting off in second gear the Swiftsure required only just over half a minute to reach 30 m.p.h. These times are adequate proof of the good relative choice of the gear ratios in relation to the engine torque and it was this rapid acceleration that was later to prove of such assistance in maintaining a high average speed during the fuel-consumption tests.

Farleigh Hill, the Thornycroft "old faithful," was the scene of the hill-climbing and brake-fade tests. This 1.4-mile-long hill has an average gradient of 1 in 27, with sections of up to 1 in 8.4 occurring past the halfway mark.

Two fast climbs were made, both in an ambient temperature of 64° F. Water temperature rose by 239 F.

to 151° F. on each occasion. The system is not pressurized, but, as this is not a hot-running engine, longer gradients under tropical conditions should not cause over-heating.

The faster of the two climbs was made in 3 minutes 58 seconds, which is equivalent to an average road speed of 21.3 m.p.h. Second and third gears were used during these climbs, the maximum road speed on the lower slopes being just under 30 m.p.h.

During both these ascents, and the subsequent stop-start test, slight smoke was noticeable in the exhaust, which tended to suggest that the engine was working at the top limit of its power output and that the fuelpump setting might have been a little generous.

Two descents were made in top gear with the foot brake applied. To restrict the speed to 20 m.p.h. on the lower slopes three=quarter throttle was used to provide increased resistance, and at the bottom of the hill on each occasion there was plenty of smell but no smoke from the drums.

After the first descent an emergency stop from 20 m.p.h. produced a Tapley meter reading of 49 per cent. and there was negligible increase in pedal travel. A second descent produced more pronounced drum heating and the pedal travel had increased by 2 in.. over its normal maximum-pressure position. Even so, the retardation rate was little affected and the maximum deceleration was recorded as 42 per cent.

After a 20-minute stop to allow the brake drums to cool down to a normal temperature, the vehicle was returned to the 1 in 8.4 section for a stop-start test. The hand brake was capable of holding the vehicle on this gradient without assistance from the foot brake, and there were several notches in hand with the vehicle stationary.

An extremely smooth and easy getaway was made in low ratio, using only a third throttle opening and I was so encouraged by this that I attempted a second-gear start, which only just failed.

A test tank holding over 2 gal. of fuel had been fitted to the chassis for my tests and with it topped up to the upper mark of the graduated sight tube, a consumption run was started in the direction of Southampton. The main road from Basingstoke carries plenty of heavy and private-car traffic, but is not wide in most parts, except for the dual carriageway of the Winchester by-pass.

Good driving visibility and the rapid acceleration enabled me to keep up a high average speed, and although I took a wrong turning at the A30-A33 fork and there were several involuntary stops for road works and badly parked vehicles, I was able to maintain an average speed of 28.2 m.p.h. on the 27.8-mile run. This outward journey included a 2-minute second-gear climb up Otterbourne Hill, but despite this and other adversities, the fuel-consumption rate was 15.9 m.p.g.

It became apparent that by "taking a run " at gradients, it would be possible to achieve a higher speed and sometimes in a higher gear ratio. I have previously found this to be a characteristic of Thornycroft oil-engined vehicles and with maximum torque of the JR6 engine occurring at 1,600 r.p.m., the Swiftsure was no exception to the rule.

I applied this technique, therefore, on the return journey to Basingstoke and was able to maintain an average speed of 29.6 m.p.h. for a mean consumption rate of 16.6 m.p.g., with reduced use of the indirect ratios and subsequent easier running of the engine. During this return run, heavy traffic was encountered on the fringes of Southampton and there were several enforced traffic halts. At no time during either of these runs was 35 m.p.h. exceeded.

On the following day, the test weights were removed but the timber tray was left on the chassis to represent an overweight body. As the vehicle stood, with full tanks, spare wheel and other non-taxable equipment, it weighed 3 tons 14cwt., showing the test body to be much heavier than a normal production platform or drop-sided assembly.

On this occasion the two runs between Basingstoke and Southampton were finished at speeds of 31 m.p.h. and 31.4 m.p.h. respectively. By combining the laden and unladen fuel-consumption rates, it is reasonable to suppose that any operator using this vehicle for services which entail a large amount of unladen running would return an overall figure of 19-20 m.p.g.

I drove the vehicle for nearly 200 riles during the two-day test and was ;enerally satisfied with the way it landled. My reactions to the peculiarities of the braking system I have already recorded. Comment must, however, be made on the front sus:. pension. No dampers are fitted, with the result that even when fully laden, travel is bouncy, particularly over secondary roads.

Lively Front Suspension This tendency. is naturally more pronounced when unladen and over anything but roads with billiardstable smoothness it is almost impossible . to keep a steady throttle opening; and frequently 1 left the driving seat altogether. It says much for the steering geometry of the Swiftsure. that the directional stability of the chassis was not affected overmuch by rough surfaces, but for the sake of the relatively small financial outlay involved, some form of damping should he applied to the front axle.

In other reSpects, driver comfort is of a high standard. The bucket-type seats give good lateral support and drivers of all shapes and sizes can be accommodated in the cab because. not only is the driving seat adjustable both vertically and horizontally, but a Thornycroft telescopic steering wheel is fitted.

Maintenance Tasks 'While the lest load was being removed for the "unladen " consumption run. I carried out several maintenance tasks on a second Swiftsure chassis. My first tasks consisted of level checks and, using the internal water filler, I was able to test the coolant level in 19 seconds.

The engine-oil level was verified in 31 seconds, this including the time taken to remove the hinged panel in the lower near-side engine cowl. Although no body was fitted to this chassis, I checked the gearbox level from underneath, as would be necessary with a finished vehicle, and, using the dipstick, it was possible to do this in 18 seconds.

A combined filler and level plug permits a visual check to be made of the rear-axle level and 47 seconds were taken on this, job. The brakefluid reservoir is clamped to the front of the steering column immediately

below the instrument cluster and took 11 seconds to check the level of the fluid.

The two Gv. batteries are stowed under the male's seatboard, being protected by a hinged cover. Fiftyfour seconds were taken to inspect the electrolyte level of the six cells. An AC oil-bath air cleaner is located below the bonnet top and to check the oil level took 1 minute 13 seconds, of which time 15 seconds was spent in removing the bonnet and 13 seconds in replacing it.

Using the Dunlop hydraulic jack, provided in the comprehensive tool kit which is a feature of all Thornycroft vehicles. I was able to jack up both wheels of each axle simultaneously for brake adjustments.

I spent 21 minutes adjusting the rear-brake units, there being one 1-in. square-headed adjuster at each wheel. The front-brake units, which each have two hexagon adjusters requiring

a Whitworth spanner, were adjusted in the total time of 21 minutes. There was no difficulty about any of these tasks.

-A third braking task was, carried out when a works fitter and myself bled the system in 4-1minutes. In addition to the four wheel units, the master cylinder was also bled during this operation.

There are two fuel-filter elements in the system and the small primary filter, which is attached to the nearside frame member just ahead of the fuel tank, was stripped, cleaned and replaced in I minute 33 seconds. The main filter is placed above the mate's footboard. being protected by a lieht steel pressing. This pressing made it difficult to see exactly what I was doing, but I removed and replaced the element in 2 minutes 40 seconds.

Having cleaned out these filters it was necessary to bleed the fuel system, which took if minutes, of whith time 40 seconds was spent in iemoving and replacing the detachable panel. Bleeding the fuel system was particularly easy, because of the convenient position of the combined injection and lift pump in relation to the level of the floorboards.

By getting underneath the engine it was possible to remove the oil-filter bowl in 35 seconds and replace it in I minute 10 seconds.

I changed a fuse in 15 seconds, the fusebox being attached to the near-sideengine cowl just ahead of

the compensated voltage control mechanism. I then vacated the cab to allow a works fitter to check the tappets for correct clearances. This he did in 4t minutes and was assisted only once when his mate turned the engine over for him.

Saving the heavy work until last, 1 filially removed the spare wheel and replaced it. Removal occupied a minute but replacement was a little more strenuous and I took 1 minute 55 seconds. .

It is not difficult to appreciate that the Thornycroft SWiftsure will find a ready market among users of 6-ton vehicles in this country and overseas. In respect of finish, performance and ease of maintenance, it sets a high standard, all of which may be obtained at a basic price of £1,495. plus £352 Gs. purchase tax.