INCREASING THE LIFE OF LUBRICATING OIL.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

By the Removal of Impurities in `Used Oil, its Period of Service is Much Extended and Bearing Wear is Reduced.

IT has been said by Mr. H. C. Ricardo, the well-known designer, that the design of the internal-combustion engine for motor-vehicle use has advanced now to such a stage that the next line of thought, having in view general economy, must be directed towards eliminating wear.

A good deal has been done, particularly in the United States, in the cleansing of the air on its way through the carburetter to the engine, because the air contains a large proportion of dust, including silica, which has a cutting effect upon bearings, and now attention is being paid in this country to this obvious improvement and also to the question of the cleansing of the lubricating oil and its recovery. In this country, again, it is more important than in the United States to increase the life of the oil, because practically the whole of it has to be imported.

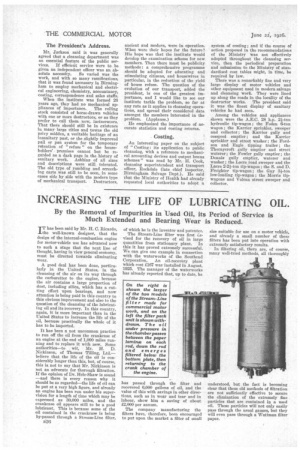

It has been a not uncommon practice to run off the oil from the crankcase of an engine at the end of 1,000 miles running and to replace it with new. Some authorities—to wit, Mr. H. D. Niekinson, of Thomas Tilling, Ltd.— believe that the life of the oil is considerably longer than this, but, of course, this is not to say that Mr. Nickinson is not an advocate for thorough filtration. If the opinion of Dr. Hele-Shaw is sound —and there is every reason why it should be so regarded—the life of oil can be put at a very high figure, and already an engine has been run under his supervision for a length of time which may be expressed as 30,000 miles, and the crankcase oil appears still to be a good lubricant. This is because some of the oil contained in the crankcase is being by-passed through a Stream-Line filter,

1326 of which he is the inventor and patentee.

The Stream-Line filter was first Ccvised for the recovery of oil in large quantities from stationary plant. In this it has proved extremely successful. We can give one example in connection with the waterworks of the Southend Corporation. An oil-recovery plant which cost £167 was installed in August, 1925. The manager of the waterworks has already reported that, up to date, he has passed through the filter and recovered 6,000 gallons of oil, and the value of this with savings in other directions, such as in wear and tear and in labour, show him a saving of about £2,000 per annum.

The company manufacturing the filters have, therefore, been encouraged to put upon the market a filter of small size suitable for use on a motor vehicle, and already a small number of these filters has been put into operation with extremely satisfactory results.

In filtering oil, there are, of course, many well-tried methods, all thoroughly understood, but the fact is becoming clear that these old methods of filtration are not sufficiently effective to secure the elimination of the extremely fine particles that are contained in a used oil. These particles will not only easily pass through the usual gauzes, but they will even pass through a Wattman filter paper.

'An analysis of used oil has shown that it contains 96 per cent. of good oil, 2.3 per cent. sludge, the rest being water and volatile fuel oils. Of the sludge 90 per cent. is found to be carbon in an extremely fine state, and the remainder consists of silica, iron and various nonferrous metals, including magnesium.

Dr. Hele-Shaw's Stream-Line filter is found to stop practically the whole of these adulterants, and the apparatus, 'which is quite small, will filter the whole of the oil in the crankcase of an engine in the course of an hour's running. We illustrate one form of the filter measuring about 9 ins, in length by 5 ins, in diameter, whilst a smaller type is being made measuring about 7 ins, in length by 31 ins, in diameter.

It is usual to jacket the filter with exhaust gas as the heat serves to drive off the water and fuel vapours. The oil is fed into the container by a bypass off the main fuel system, because it would require a very large filter to treat the whole of the oil on its way from the base chamber to the main and other bearings of an engine. It is found quite sufficient, however, to by-pass so much as will enable the whole of the contents of the base chamber to be filtered, as we have said, in the course of an hour's running.

Immersed in the oil in the main chamber is a nest of filter packs. Each pack consists of a square rod upon which are threaded a large number of thin papsr discs, the paper being treated in such a way as to be impervious to oil. The discs are pressed tightly together, so tightly that only the minute robustness on the surface of the paper serves to provide a path for the very fine molecules of oil, this path, however, being buch too restricted to pass the fine particles suspends in the oil.

There is no particular merit about the use of paper, except that it is the most convenient material from which to build up the laminte. Metal discs would effect the filtration, but not so perfectly, as it would be impossible to secure the same resilience as is provided by paper.

• Only a small pressure difference is necessary in order to secure a passage for the oil between the paper discs. It can be as low as 2 lb., but generally a pressure of 4 lb. is employed, and it can . be as high as the pressure in the lubricating system of any engine in presentday use. The oil having passed between the laminae, enters the circular space formed by the round holes punched in the paper disc, the rods passing through the centres of the discs being square. The clean oil passes down the rods s nd is led back to the base chamber of the engine.

There is another way of securing the pressure difference, and that is by means

of a vacuum, using the minus pressure which is set up in the induction pipe. In this case the steam and petrol vapour given off by the heated oil are drawn into the engine and consumed, but where pressure by pump is employed steam and vapour are allowed to escape into the air.

So far the only original part about the method is the employment of paper as a means of filtering the oil, but the next original part lies in the cleansing of the filter.

This, as it happens, is simplicity itself, for a valve is fitted on the clean oil side of the filter, to which the connec

tion of an ordinary tyre inflator may be attached. A small pressure from the inflater, which is applied, therefore, in the reverse direction to the flow of oil, blows from the edges of the filter, the whole of the sludge collected there. This drops to the bottom of the container ready to be drawn off.

The filters have been run for a considerable time and, so far, it has not been found necessary to replace the paper discs on any one of them, and the only attaition necessary is the occasional cleaning of the filter ix the manner described, say, once to every 2,000 miles of running.

We illustrate a filter pack unit, the diameter of the paper discs on each of the rods shown being about half an inch. The filter in an earlier form is shown fitted to a Leyland lorry engine.

We understand that the price of the Stream-Line filter is £3 3s., with a reduction for large quantities, the price being practically the same for both the sizes that we have mentioned, because the main cost of manufacture lies in the assembly of the pack units.

The name and address of the company marketing the filter are the Stream-Line Filter Co., Ltd., 64, Victoria Street, London, S.W.1.