THE NEW MAUDSLAY CHAR-A-BANCS CHASSIS.

Page 10

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

Designed Chiefly for Long Distance Touring Over Roads of Different Characteristics ; Efficiency and Flexibility are its Main Attributes.

FOREMOST desiderata in the mind of the prospective ehar-à-bancs buyer would naturally be to employ a vehicle possessing flexibility of power-output, adequate for varying characteristics of any long-distance touring schemes which he intends to exploit. He would also be favourably impressed by a machine presenting a "clean," yet robust, appearance. But, of special import tcehim would be whether "proved efficiency" was the keynote of the product—as shown by the vehicle's grade of service through the years of private enterprise, as well as in stress of national need.

Without further preamble, the Maudslay chassis under present review, which we have often inspected under passenger-carrying and goods-transport conditions, essentially embodies the afore-mentioned cardinal points. For example, let us consider, en passant, the maker's claim for a well-proportioned and robust layout, as exemplified in the chassis framing. There is not a single rivet used in it from end to end. With its economical section of straightrolled channel and wrought-steel cross tubes, of generous diameter, a cleaner and more , judiciously designed piece of framework it would be unnecessary

to wish for.

A Remarkable Engine with Very Accessible Parts.

For the power-unit a vertical engine is employed,

the R.A.O. rating of which is 32.2 h.p. Its four cylinders are cast in pairs, and bored out to 4-i ins., the stroke-being 5 ins. An ingenious form of caststeel sandwich-flange, with an aperture of Si ins. by 3 ins., is utilized for rigidly connecting the cylinder pairs, so that, in effect, the result is a monobloc construction, but with the decided advantage of

economical replacement or overhaul. Moreover, the extra large openings thus provided in the waterjacket permit of a liberal-sized core for casting needs, as well as affording an unrestricted water fairway betweekthe cylinders. A total absence of pockets is a feature of the combustion-chamber, consequently it is machined

throughout—an important consideration as regards provision against undue carbonization and preignition. The Matidslay practice of disposing the valves with their operating gear directly overhead, of eourse, obtains on this 'model. In the camshaft drive is incorporated a unique type of ball-universal joint. This permits of the shaft-casing, with its tappet gear, being hinged over quite clear of the valves. Each valve, which operates in an independent cast-iron, box, may then readily be withdrawn from the cylinders after simply unscrewing a holding-down nut provided for each box. Thus all valves and seats can be inspected or reground quite apart from the engine.

The water-circulating system is in duplicate, and the stuffing-gland of the. centrifugal pump is .noticeable by its ease of access. A well-balanced aluminium fan induces ak.good air-draught through the tubeblock of an imposing cast and bailt-up radiator. A hot-water jacket surrounds the.induction pipe, which is served by the Zenith make of carburetter. The firing charge is 'ignited through the aid of a H.T. magneto, which is driven by an adjustable silent chain.

The motor, being essentially of the high-duty order, is supplied with a five-bearing crankshaft, the journals and crankpins of which are ground and polished to within extra-fine working limits. This prime component is suspended in the top portion of the crank chamber. Here, in particular, is the trained mind of the experienced engineer very evident, inasmuch as the explosion stresses are not transmitted through the aluminium casing, but are resisted by high-tensile steel bolts that extend all the way from the cylinder-base flanges to the exterior of the base chamber. They are, indeed, veritable foundation bolts. Noticeably light con struction of crank chamber is. thus permissible, and it is carried on a sub-frame.

Oil is conducted under pressure through suitable ducts leading to each main bearing, crank pin and connecting-rod wrist pin. This particular manufacturing 'company exploited and perfected this method of primary lubrication many years before its qualities were fully recognized throughout the industry. Before leaving the engine one must refer to the, unusual and desirable provision made for withdrawing the pistons and connecting rods. These parts can be taken adrift through the extra large doors in the crankcase sides. This facility is made possible by the valves and their gear being disposed overhead.

Smooth Drive and Double Clutching Facilitated.

A reversed cone clutch, Ferodo-lined, transmits the engine. torque, and it is quite an easy matter to renew the friction fabric. The spring thrust is selfcontained, and ready means of adjustment are provided. There is a ball ring for taking up the end thrust. That very important feature, clutch .spigor;§ . lubrication, has received due attention.

Every wise .driver nowadays, when necessary, resorts to "double clutching" when changing down, and the Maudslay clutch stop iz admirably adapted to quick, but smooth action, chiefly on account of its liberal proportions and construction. A double banjo form of spring plate, faced with Ferodo, extends from side to side of the sub-frame, thus providing a very efficient type of auxiliary frictionmember.

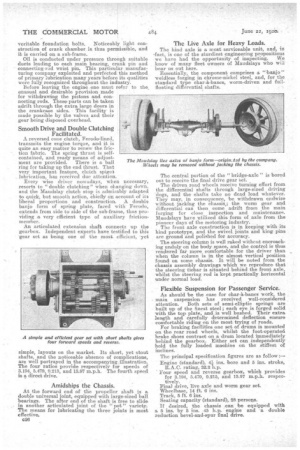

An articulated extension shaft connects up the gearbox. Independent experts have testified to this 'gear set as being one of the most efficient, yet

simple, layouts on the market. Its short, yet stout shafts, and the noticeable absence of complications, are well portrayed in the .accompanying illustration. The four ratios provide respectively for speeds of 3.194, 5.479, 9.215, and 15.97 m.p.h. The fourth speed is la, direct drive.

Amidships the Chassis.

At the forward end of the propeller shaft is a double universal joint, equipped with large-sized ball bearings. The after end of the shaft is free to slide in another articulated joint of the "pot" variety. The means for lubricating the three joints is most effective, c26

The Live Axle for Heavy Loads.

The hind axle is a most serviceable unit, and, in -fact, is one of the sturdiest engineering propositions we have had the opportunity of inspecting. We know of many fleet owners of Maudslays who will bear us out here.

Essentially, the component comprises a "banjo" weldless forging in chrome-nickel steel, and, for the standard type char-aebancs, worm-driven and fullfloating differential shafts.

The central portion of the " bridge-axle " is bored out to receive the final drive gear set.

The driven road wheels receive turning effort from the differential shafts through large-sized driving dogs, and the shafts take no dead load whatever. They may, in consequence, be withdrawn endwise 'without jacking the chassis; the worm gear and differential can then tome adrift from the main forging for close inspection and maintenance. Maudslays have utilized this form of axle from the pioneer days of the motoring industry..

The front axle 'construction is in keeping with its hind prototype, and the swivel joints and king pins are ground and polished for accuracy.

The steering column is well raked -without encroaching unduly on the body space, and the control is thus rendered far inore comfortable for the driver than when the column is in the almost vertical position found on some chassis. It will he noted from the chassis assembly drawings which we reproduce that the steering tiebar is situated behind the front axle. Whilst the steering rod is kept practically horizontal under normal load.

Flexible Suspension for Passenger Service.

As should be the cane for char4-bancs work, the main suspension has received well-considered attention. Both sets of semi-elliptic springs are built up of the finest steel; each eye is forged solid with the top plate, and is well bushed. Their extra length and carefully determined deflection ensure 'comfortable riding on the most trying of roads. For braking facilities one set of drums is mounted on the rear road wheels, whilst the foot-operated brake shoes contract on a drum located immediately behind the gearbox. Either set can independently hold the fully loaded machine on the stiffest of The principal specification figures are as follow :

Engine (standard), 4.1-, ins, bore and 5 ins. stroke, R.A.C. rating, 32.2

Four speed and reverse gearbox, which provides for 3.194, 5.479, 9.215, and 15.97 m.p.h. respectively. Final drive, live axle and worm gear set. Wheelbase, 14 ft. 6 ins. Track, 5 ft. 6 ins. Seating capacity (standard), 28 persons.

If desired, the chassis can be equipped with a. 5 ins. by 5 ins. 45 h.p. engine and a double reduction bevel-and-spur final drive.