Details of the Girling Trade Carrier.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

In our issue of the 4th May last, we reproduced three photographs and briefly outlined a new trade carrier, which had been constructed by Girling Motors, Ltd., of 23, Upper Market Street, Woolwich, SE. At that time, we purposely refrained from giving a long detailed description, because only one machine had then been built, and the experiments were not quite complete Since that time, the makers have re-designed the machine, and have produced what promises to he a very-practical vehicle for small tradesmen.

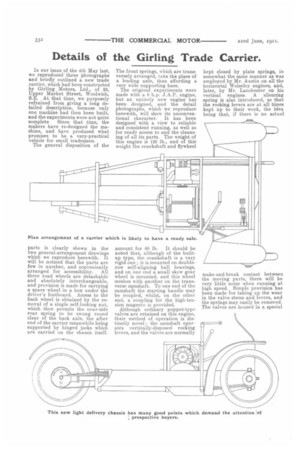

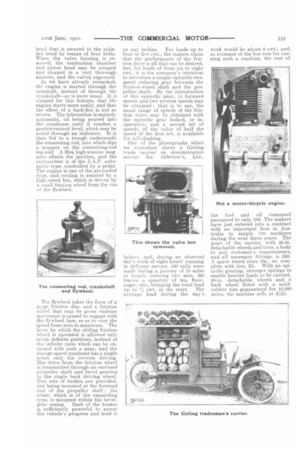

The general disposition of the parts is clearly shown in the two general-arrangement drawings which we reproduce herewith. It will be noticed that the parts are few in number, and conveniently arranged for accessibility. All three road wheels are detachable and absolutely interchangeable, and provision is made for carrying a spare wheel in a box under the driver's footboard. Access to the back wheel is obtained by the removal of a single self-locking nut, which then permits the near-side rear spring to be swung round clear of the back axle, the after end of the carrier meanwhile being supported by hinged jacks which are carried on the chassis itself. The front springs, which are transversely arranged, take the place of a leading axle, thus affording a very wide supporting base. The original experiments were made with a 6 h.p. J.A.P. engine, but an entirely new engine has been designed, and the detail photographs, which we reproduce herewith, will show its unconventional character. It has been designed with a view to reliable and consistent running, as well as for ready access to and the cleansing of all its parts. The weight of this engine is 120 lb., and of this weight the crankshaft and flywheel account for 68 lb. It should be noted that, although of the builtup type, the crankshaft is a very rigid one ; it is mounted on doublerow self-aligning ball bearings, and on one end a small skew gear wheel is mounted, and this wheel meshes with another on the transverse camshaft. To one end of the camshaft the starting handle may be coupled, whilst, on the other end, a coupling for the high-tension magneto is provided. Although ordinary poppet-typo valves are retained on this engine, their method of operation is distinctly novel the camshaft operates vertically-disposed rocking levers, and the valves are normally kept closed by plate springs, in somewhat the same manner as was employed by Mr. Austin on all the horizontal Wolseley engines, and, later, by Mr. Lanchester on his vertical engines. A silencing spring is also introduced, so that the rocking levers are at all times kept up to their work, the idea being that, if there is no actual make-and-break contact between the moving parts, there will be very little noise when running at high speed. Simple provision has been made for taking up the wear in the valve stems and levers, and the springs may easily be removed. The valves are housed in a special

head that is secured to the cylinder head by means of four bolts. When the valve housing is removed, the combustion chamber and piston head may be scraped and cleaned in a very thorough manner, and the valves reground.

As we have already remarked, the engine is started through the camshaft, instead of through the crankshaft—as is more usual. It is claimed for this feature, that the engine starts more easily, and that the effect of a back-fire is not so severe. The lubrication is entirely automatic, oil being poured into the crankcase until it reaches a predetermined level, which may be noted through an indicator. It is then fed to a trough underneath the connecting rod, into which dips a scupper on the connecting-rod big-end. A Mea high-tension magneto effects the ignition, and the carburetter is of the J.A.P. automatic type, controlled by a pedal. The engine is one of the air-cooled type, and cooling is assisted by a high-speed fan, which is driven by a small friction wheel from the rim of the flywheel.

The flywheel takes the form of a large friction disc, and a friction wheel that may be given endwise movement is caused to engage with the flywheel face, so as to vary the speed from zero to maximum. The lever by which the sliding friction wheel is operated is allowed only seven definite positions, instead of the infinite ratio which can be obtained with such a gear, and the change-speed quadrant has a single notch only for reverse driving. The drive from the friction wheel is transmitted through an enclosed propeller shaft and bevel gearing to the single back driving wheel. Two sets of brakes are provided, one being mounted at the forward end of the propeller shaft ; the other, which is of the expanding type, is mounted within the bevelgear casing. Each of the brakes is sufficiently powerful to arrest the vehicle's progress and hold it

on any incline. For loads up to four or five cwt., the makers claim that the performance of the friction drive is all that can be desired, but, for loads of from six to eight cwt., it is the company's intention to introduce a simple epicyclic twospeed reducing gear between the friction-wheel shaft and the propeller shaft. By the introduction of this epicyclic gear, 14 forward speeds and two reverse speeds may be obtained ; that is to say, the usual range of speeds of the friction drive may be obtained with the epicyclic gear locked, or inoperative, and a second set of speeds, of the value of half the speed of the first set, is available for hill-climbing. One of the photographs which we reproduce shows a Girling trade carrier on demonstration service for A hierton's, Ltd.,

bakers, and, during an observed day's work of eight hours' running in delivery service, 190 calls were made during a journey of 13 miles in length. carrying two men, 260 loaves, a quantity of tea, flour, sugar, etc., bringing the total load up to 71 cwt, at the start. The average load during the day's work would be about 6 cwt., and, as evidence of the low cost for running such a machine, the cost of the fuel and oil consumed amounted to only 10d. The makers have just entered into a contract with an important firm in Australia to supply 110 machines during the next three years. The price of the carrier, with 26-in. detachable wheels and tires, a body to suit customer's requirements, and all necessary fittings, is 295. A spare wheel costs 35s., or, complete with tire, £5. With an epicyclic gearing, stronger springs to enable heavier loads to be carried, 28-in, detachable wheels and a back wheel fitted with a solidrubber tire guaranteed for 10,000 miles, the machine sells at 2125.