WHY D] THEY DO IT?

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

Asks P. G. Tuckel

e Story Behind the Design .d Building of Britain's Most gconventional Road Vehicle nver Unit—The Calmer TS3.

THE unconventional design of the Commer TS3 two-stroke oil engine has led many people to ask why it should have been adopted by a company making its first compression-ignition unit. It is natural that certain difficulties should have been experienced during the course of its development, but what were their nature and how were they overcome?

Because of the remarkable success of this engine, I set out to seek answers to these and many other questions regarding the only opposed-piston unit produced in this country for use in road transport vehicles.

When Commer Cars, Ltd., first decided to build an oil engine, it was considered essential to embody within the specification certain fundamental characteristics. Briefly, these embraced the following: (1) Minimum billk and weight; (2) a low rate of fuel consumption; (3) minimum basic cost: (4) ease of maintenance and (5) a performance at least equal to that given by the company's petrol engines.

The four-stroke in-line engine was ruled out, because it was thought that it could not achieve the high aims which the designers had set themselves. Even reckoning on the added complication of using a blower, it was considered that, overall, the two-stroke engine offered simplicity, greater ease of maintenance and lower weight, and that in the opposed-piston type, which had already been proved in other fields, could be found a unit of high thermal efficiency and hence one which would return good fuel-consumption figures.

An examination of the design principles embodied in the engine now being produced will show how these promises have been realized.

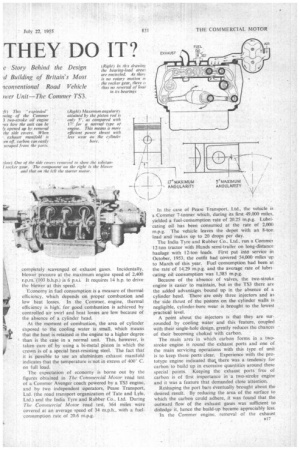

The performance of a two-stroke engine depends in great measure on the thoroughness with which the cylinders are scavenged. The opposed-piston unit lends itself to the uniflow system of scavenging, which means that the scavenging air is introduced through one set of ports—the inlet—and flows in one direction to find an exit at the exhaust ports.

al6 As the porting of the cylinders is on the Kadenacy principle, in which ample port area permits the escape of the exhaust gases with such momentum that a partial vacuum is created behind them, recharging of the cylinder is materially assisted.

The inlet ports open 25° after the exhaust ports, and the uniflow movement of the air which enters under pressure from the blower ensures that the cylinder is completely scavenged of exhaust gases. Incidentally, blower pressure at the maximum engine speed of 2,400 r.p.m;(103 b.h.p.) is 6 p.s.i. It requires 14 h.p. to drive the blower at this speed.

Economy in fuel consumption is a measure of thermal efficiency, which depends on proper combustion and low heat losses. In the Commer_ engine, thermal efficiency is high, for good combustion is achieved by controlled air swirl and heat losses are low because of the absence of a cylinder head.

At the moment of combustion, the area of cylinder exposed to the cooling water is small, which means that the heat is retained in the engine to a higher degree than is the case in a normal unit. This, however, is taken care of by using a bi-metal piston in which the crown is of a special heat-resisting steel. The fact that it is possible to use an aluminium exhaust manifold indicates that the temperature is not in excess of 400° C. on full load.

The expectation of economy is borne out by the figures obtained in The Commercial Motor road test of a Commer Avenger coach powered by a TS3 engine, and by two independent operators, Pease Transport, Ltd. (the road transport organization of Tate and Lyle, Ltd.) and the India Tyre and Rubber Co., Ltd. During The Commercial Motor road test. 364 miles were covered at an average speed of 34 m.p.h., with a fuelconsumption rate of 20.6 m.p.g. In the case of Pease Transport, Ltd., the vehicle is Commer "7-tonner which, during its first 49,000 miles. yielded a fuel-consumption rate of 20.25 m.p.g. Lubricating oil has been consumed at the rate of 2,000 m.p.g. The vehicle leaves the depot with an 8-ton load and makes up to 20 drops per day.

The India Tyre and Rubber Co., Ltd., run a Commer 12-ton tractor with Hands semi-trailer on long-distance haulage with 12-ton loads. First put into service in October, 1953. the outfit had covered 54,000 miles up to March of this year. Fuel consumption had been at the rate of 14.29 m.p.g. and the average rate of lubricating oil consumption was 1,385 m.p.g.

Because of the absence of valves, the two-stroke engine is easier to maintain, but in the TS3 there are the added advantages bound up in the absence of a cylinder head. There are only three injectors and as the side thrust of the pistons on the cylinder walls is negligible, cylinder-bore wear is brought to the lowest practical level.

A point about the injectors is that they are surrounded by cooling water and this feature, coupled with their single-hole design, greatly reduces the chances of their becoming choked with carbon.

The main area in which carbon forms in a twostroke engine is round the exhaust ports and one of the main servicing operations with this type of unit is to keep these ports clear. Experience with the prototype engine indicated that there was a tendency for carbon to build up in excessive quantities around these special points. Keeping the exhaust ports free of carbon is of first importance in a two-stroke engine and it was a feature that demanded close attention.

Reshaping the port bars eventually brought about the desired result. By reducing the area of the surface to which the carbon could adhere, it was found that the outward flow of the exhaust gases was sufficient to dislodge it, hence the build-up became appreciably less.

In the Commer engine, removal of the exhaust manifold is straightforward and there is no need to withdraw the pistons when decarbonizing. Being on top of the engine, the injection pump and auxiliaries are readily accessible for servicing.

Usually it is not practicable to provide inspection covers on a crankcase but, in the case of the TS3, removable side covers enable the main rockers, bearings, pistons and other units to be examined.

Compact and Light Bulk and weight requirements were largely met in the basic design, because an opposed-piston engine must of necessity be compact, whilst the absence of valve gear and a cylinder head saves a great deal of weight. Complete with auxiliaries, the TS3 engine weighs 1,000 lb., which is below the average for a unit of comparable power.

An important feature associated with opposed-piston engines of the TS3 type is that the load stresses in the rocker mechanism are unidirectional, that is, except at high speed, there is no reversal of loading on the bearings, as in the case of a normal engine. Coupled with this is the fact that the degree of movement of the pins in the hearings or the bearings round the pins is so slight as to be of little assistance in distributing the oil.

Bearings most concerned are those supporting the gudgeon pin and those in the rocker arm. It is normal practice to introduce an oil feed into a bearing in the area of the lightest load, but if this practice were adopted in the present case, the area most needing protection would be completely starved.

This is a feature to which much attention has been devoted and highly successful results have been attained by adopting shapes of oil grooving calculated to give the biggest spread of oil within the limited assistance given by the small oscillatory movement of the respective members.

Theoretically, a multi-cylindcred opposed-piston engine should produce a unit of almost perfect balance, and although the Commer TS3 is superior in this respect, the ultimate has not been achieved. In a common cylinder, one piston is slightly out of phase with the other for reasons associated with linkage

geometry, as well as to assist in giving an exhaust lead

of 250 with a subsequent air overlap of I In other words, a non-symmetrical condition is achieved without complication.

The compression ratio of )9 to 1, as calculated, becomes an effective ratio of 16 to 1 when measured from the point at which the inlet ports are covered.

The slight out-of-balance which results from thus arranging the pistons out of phase is more than cornpensated by cooler running and better use of the fuelair mixture, factors which have a material bearing on general efficiency and fuel economy.

No unusual machining problems are presented in building the engine. The cylinder liners are, however, of a character demanding close adherence to specified tolerances. Being of the wet type, they have to be sealed against water leakage not only at the ends, but at intermediate points denoting the inlet and exhaust belts.

Sealing Cylinder Liners Sealing is achieved by machining the collars formed in the casting to perform the function of an unsplit piston ring. They are finished ground 0.004-in, oversize in respect of the stations machined in the block and, before being pressed home, the lips are smeared with sealing compound. As the liners are located in the block by the injector mounting sleeve, a jig is 'called for to ensure precision.

This, then, is the story of the first oil engine to be produced by the Rootes Group with the initial object of providing an alternative power unit for the Commer Avenger passenger chassis. Its many outstanding operational features, however, in which economy in fuel is prominent, soon attracted the goods-vehicle operator, with the result that it is now being employed in numerous types of service. The unit-is being produced in the Group's Tilling-Stevens works at Maidstone, Kent.

To tackle the unconventional requires great courage, especially in an organization which must base production on large quantities. In the case of the TS3, the enterprise has succeeded and the natural conservatism of commercial-vehicle operators has quickly been overcome.