Disc Brakes for Heavies Soon

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

Why Caliper-type Disc Brakes Will Solve Many Major Problems. High Contact Pressure Means Absence of Squeal John M. Simpson

THE use of disc brakes on British heavy commercial vehicles will not be long delayed. The type to be used will be that known as the caliper brake, the reasons for which will be outlined later.

During the course of development of such an important new feature, thc operator must always be borne in mind. He must be given unquestionable reliability, and initial cost and the cost of spares must be low. Essential, too. are easy maintenance and long life. Combined with these essentials it must he assumed that the disc brake will give as good if not a superior performance to that of the present drum type.

The internal-expanding drum-type ',Take. as now used, has not yet reached its zenith of development in the commercial vehicle sphere. It has, however. inherent faults which no amount of development could enable it to face up to the formidable competition of the disc brake. the action of which offers a standard of smoothness and consistency with which the drum-type brake cannot compare.

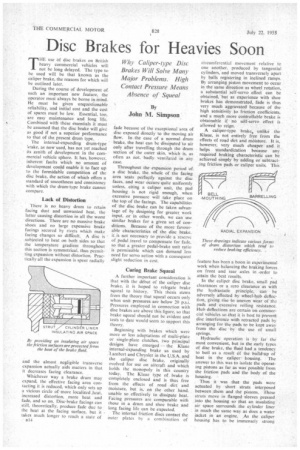

Lack of Distortion There is no heavy drum to retain facing dust and unwanted heat. the latter causing distortion in all the worst directions. lhere are no massive brake shoes and no large expensive brake facings secured by rivets which make facing changes so difficult. A disc is subjected to heat on both sides so that the temperature gradient throughout this section is symmetrical, thus permitting expansion without distortion. Practically all the expansion is spent radially

and the almost negligible transverse expansion actually aids matters in that it decreases facing clearance.

Whichever way a brake drum may expand, the effective facing area contacting it is reduced, which only sets up a vicious circle of more localized heat, increased distortion, more heat and fade, and so on. Disc-brake facings can still, theoretically, produce fade due to the heat at the facing surface, but it takes much longer to reach a state of

B14

fade because of the exceptional area of disc exposed directly to the moving air flow. In the case of a normal drum brake, the heat can be dissipated to air only after travelling through the drum section of the outer skin, which is. as often as not, badly ventilated in any case.

Throughout the expansion period of a disc brake, the whole of the facing area seats perfectly against the disc faces, and wear occurs quite uniformly unless, citing a caliper unit, the pad housing is not rigid enough, when excessive pressure will take place on the top of the facings. The capabilities of the disc brake can be taken advantage of by designing for greater work input, or in other words, we can use similar brakes for a given set of conditions. Because of the more favourable characteristics of the disc brake, it is not necessary to provide a reserve of pedal travel to compensate for fade, so that a greater pedal-brake unit ratio is permissible which can demand less need for servo action with a consequent slight reduction in cost.

Curing Brake Squeal

A further important consideration is that with the debut of the caliper disc brake, it is hoped to relegate brake squeal to history. This thesis stems from the theory that squeal occurs only when unit pressures arc below 20 p.s.i. Pressures employed in connection with disc brakes are above this figure. so that brake squeal should not be evident and tests to date would seem to support this theory.

Beginning with brakes which were more or less adaptations of multi-plate or single-plate clutches, two principal designs have emerged — the Klauc internal-expanding brake as used by Lambert and Chrysler in the U.S.A. and the caliper disc brake, originally evolved for use on aircraft and which holds the monopoly in this country today. The Klauc type of brake is completely enclosed and is thus free from the effects of road dirt and moisture. hut is. on the other hand, unable so effectively to dissipate heat. Facing pressures are comparable with those in a drum and shoe brake and long facing life can be expected.

The internal friction discs contact the outer plates by a combination of circumferential movement relative to one another, produced by tangential cylinders, and moved transversely apart by balls registering in inclined ramps. By arranging piston movement to occur in the same direction as wheel rotation, a substantial self-servo effect can be obtained, but as experience with shoe brakes has demonstrated, fade is thus very much aggravated because of the high sensitivity to friction coefficients. and a much more controllable brake is obtainable if no self-servo effect is allowed to reign.

A caliper-type brake unlike the Klaue, is not entirely free from the effects of road dirt and moisture. It is, however, very much cheaper and it helps standardization because any required braking characteristic can be achieved simply by adding or subtracting friction pads or caliper units. This feature has been a boon in experimental work when balancing the braking forces on front and rear axles in .order to attain the best results.

In the caliper disc brake, small pad clearances or a zero clearance as with the hydrastatic principle, can he adversely affected by wheel-hub deflection, giving rise to uneven wear of thc pads and excessive rolling resistance. Hub deflections are certain on commercial vehicles so that it is best to prevent disc interference with retracted pads by arranging for the pads to be kept away from the disc by the use of small springs.

Hydraulic operation is by far the most convenient, but in the early types of disc brake, the fluid had a tendency to boil as a result Of the build-up of heat in the caliper: housing. The answer to this was to isolate the operating pistons as far as was possible from the friction pads and the body of the housing.

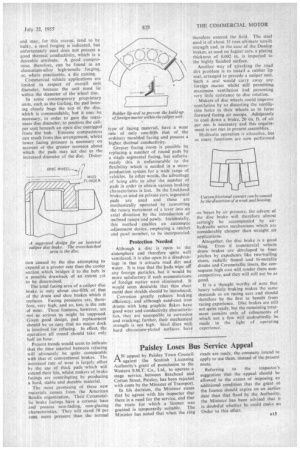

Thus it was that the pads were actuated by short struts interposed between them and the pistons. These struts move in flanged sleeves pressed into the housing so that an insulating air space surrounds the cylinder liner in much the same way as does a water jacket in an engine. As the caliper housing has to be immensely strong and may, for this reason, tend to be bulky, a steel forging is indicated, but unfortunately steel does not possess a good thermal conductivity, which is a desirable attribute. A good compromise, therefore, can be found in an aluminium-alloy high-tensile forging, or, where practicable, a die casting.

Commercial vehicle applications are limited in respect of overall unit diameter, because the unit must lie within the diameter of the wheel rim.

In some contemporary proprietary dnits, such as the Girling, the pad housing closely hugs the top of the disc, which is commendable, but it may be necessary, in order to gain the maximum disc diameter, to position the caliper unit beneath an open disc outriggcd from the hub. Extreme compactness can result from this arrangement, whilst lower facing pressure is necessary on account of the greater moment about which the pads may act due to the increased diameter of the disc. Distor tion caused by the disc attempting to expand at a greater rate than the cooler section which bridges it to the hub, is a possible drawback of an extent yet to be determined.

The total facing area of a caliper disc brake is only about one-fifth of that of the drum and shoe brakes which it replaces. Facing pressures are, therefore, very high, and so, too, is the rate of wear. These features, however, are not as serious as might be supposed. Given good design, pad replacement should be so easy that no major dock is involved for refacing. In effect, the operation all round should take only half an hour.

Present trends would seem to indicate that the time interval between refacing will ultimately be quite comparable with that of conventional brakes. The increased rate of wear is largely offset by the use of thick pads 'which will extend their life, whilst makers of brake facings are contributing by producing a hard, stable and durable material.

The most promising of these new materials comes from the American Bendix organization. Their Cerametallic brake facings have a ceramic base and possess non-fading, non-glazing characteristics. They will stand 50 per cont, more pressure than the normal type of facing material, have a wear rate of only one-fifth that of the ordinary moulded facing and possess a higher thermal conductivity.

Greater facing room is possible by replacing a number of round pads by a single segmental facing, but unfortunately this is unfavourable to the flexibility which is needed in a massproduction system for a wide range of vehicles. In other words, the advantage of being able to alter the number of pads in order to obtain various braking characteristics is lost. In the Lockheed brake, as used on private cars, segmental pads are used and these are mechanically operated by converting the rotary movement of a lever into an axial direction by the introduction of inclined ramps and pawls. Incidentally, this method enables an automatic adjustment device, employing a ratchet and pawl member, to be incorporated.

Protection Needed

Although a disc is open to the atmosphere and therefore quite well ventilated, it is also open to a disadvantage in that it attracts road dirt and water. It is true that the 1,ads wipe off any foreign particles, but it would be more satisfactory if such accumulations of foragn matter were eliminated. It would seem desirable that thin sheet metal dust shields should be introduced.

Corrosion greatly reduces braking efficiency, and although sand-cast iron drums with long graphite flakes have good wear and conductivity characteristics, they are susceptible to corrosion and cracking; further, their mechanical strength is not high. Steel discs with hard chromium-plated surfaces have therefore entered the field. The steel used is of about 35 tons ultimate tensile strength and, in the case of the Dunlop brakes, as used on Jaguar cars. a plating thickness of 0.002 in. is imparted to the highly finished surface.

Another way of attacking the road dirt problem is to install a rubber lip seal, arranged to precede a caliper unit. Such a seal would carry away any foreign matter whilst still permitting maximum ventilation and presenting very little resistance to disc rotation.

Makers of disc wheels could improve ventilation by so distorting the ventilation holes in their wheels as to form forward facing air scoops. Adeijuately to cool down a brake, 20 Cu. ft. of air per sec. is necessary and this requirement is not met in present assemblies.

Hydraulic operation is attractive, but as many functions are now performed on 'buses by air pressure, the advent of the disc brake will therefore almost certaitily be accompanied by airhydraulic servo mechanisms which arc considerably cheaper than straight air applications.

Altogether. the disc brake is a good thing. Even if commercial vehicle drum brakes are developed to finer piiches by expedients like two-trailing shoes, radially finned and bi-metallic drums and Cerametallic liners. thc consequent high cost will render them noncompetitive, and they will still not be as good.

It is a thought worthy of note that heavy vehicle braking makes the same demands as on racing cars and should therefore be the first to benefit from racing experience. Disc brakes are still not quite ready, but the remaining treatment consists only of refinements of which not a few will undoubtedly be made in the light of operating experience.