MAKE-DO-AN

Page 20

Page 21

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

IIEND in the Mc

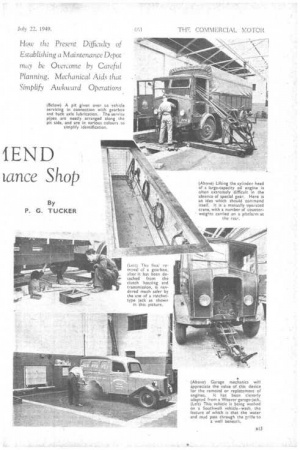

Lance Shop By P. G. TUCKER EVERY operator who has tried to expand his garage or maintenance depot or acquire a new one knows that he is knocking his head against a brick wall—but not the wall he seeks to erect. He will probably echo the recent complaint of Mr. B. G. Turner, chairman of the Road Haulage Association, that the Ministry of Transport is not of the slightest use to operators in , obtaining :licences from the appropriate Government Department.

In any event, if he could secure. the licences, he would probably be unable to find the land. If he obtained the ground, the development charge might well cause him to have second thoughts, if nothing worse.

The Next Best Thing The only solution of the problem, for the time being, seems to be to buy or rent existing property and then, by careful planning and mechanical ingenuity, adapt it to provide amenities as nearly as possible comparable with those of a maintenance shop (for it is that department with which I am particularly concerned) designed for the purpose.

First of all, let me give a broad outline of the requirements of a depot that would be capable of effecting the replacement of all major component parts, but not of carrying out engine rebuilding as a recognized thing. . It would, however, have a number of machine tools installed, so that facilities would always be available for -naking emergency replacements in he event of essential spares being in short supply, or otherwise difficult to acquire in a specified time. ,

Some Essential Facilities There would be a smith's shop, with facilities for both gas and electric welding. and possibly radiator rebuilding and repairing. There would be a department given over to engine overhauls, as opposed to engine rebuilding, and means for rernetalling and boring both connecting rods and main bearings would undoubtedly be worth providing.

A main store, in which would be carried a full range of those spares which operating experience has shown to be most frequently required, ranks as a first essential, and wherever possible it should be on the ground floor. This removes the necessity of erecting power lifting-gear, whilst the heavier components, such as road springs, are made available with greater facility.

Ample floor space will be needed for vehicle accommodation and, a generous area will be required for the sinking of pits, the erection of work benches, the installation of a proper vehicle wash, and so on.

The main building, in which no doubt the stores will be located, should provide for general offices, a spares counter and possibly a general leception and inquiry office.

What is a reasonable minimum total floor area for such a depot, and how should the available space be laid out to the best advantage? By way of giving the answers to these questions,! do not think I can do better than to cite the new premises recently opened by John 1.

Thornycroft and Co., Ltd., at 363-365, Clapham RoadkLondon, S.W.9. Admittedly this is a vehicle maker's service depot, but it functions in a similar manner to a depot run by a fleet operator.

The circumstances leading to the selection of these premises were much in line with the instances that I have already cited; it was a case of taking the best available, both in respect of size and ultimate possibilities.

An Upstairs Stores The total area, including the forecourt, is 24,000 sq. ft., of which the offices and part of the stores acount for 4,888 sq. ft. A large area of the stores, which, incidentally, could not be arranged on the ground floor, comes over the garage and, accepting a first-floor stores as inevitable, a King 2-ton electric hoist has been installed for lifting the spares crates straight off the vehicle delivering them.

Installed in the stores is a Marryatt and Scott lift of the type used in some restaurants. This service lift is used for lowering the spares to the ground floor, so that the disadvantage of an upstairs stores is largely overcome. The fleet operator who was compelled to arrange his stores upstairs would, no doubt, dispense with such a lift, as the heavy components could be lowered by means of the hoist and the smaller spares could be carried down.

Regarding the garage, which is of generous floor area, there is a dividing wall which runs down, roughly, the centre. In one section there is a pit which extends for nearly the whole length of the garage. It is arranged within a few. feet of the dividing wall against which there is built a series of benches with locker space beneath each.

As practically the whole of the roof is of glass, the natural lighting is good, but for night work or in other circumstances when the natural light is not good enough, there is a series of fluorescent tubes which, I noted, were arranged at an angle to the bench line. The object of this is to avoid the creation of shadows, such as a parallel arrangement of the lighting promotes A pit depth of 4 ft. has been chosen, as experience has shown that any lesser depth causes some inconvenience to mechanics and fitters.

Another point, too, is that the floor is virtually flat; there is a 'slight slope from each end towards, the middle, but it is so gradual as. to be scarcely apparent to the men working in the pit. The floor is cleaned by means of a squeegee.

Pit lighting is by flame-proof and vapour-proof lamps. As the modern tendency is to use fluorescent lighting in pits, I asked the manager of the depot, Mr. L. A. Harrington, why he had not adopted it. His reply was that the fluorescent tube, as now supplied for garage use, was not flame-proof, and he did not want to install a system that would, in diie course, call for modification.

Use of Fluorescent Lighting This is a point of which fleet operators will take note, although, so far as I know, insurance companies have raised no serious objections to the use of fluorescent lighting in garage pits. I was given to understand by the General Electric Co., Ltd., that the fluorescent tubes at present installed in numerous garages are not flame-proof, so that their adoption would not seem to-contravene any fire-prevention regulations.

As white tiles were not available, white-faced glazed bricks have been used to face the pit walls, and they certainly form an excellent substitute.

On the other side of the wall there is a second long pit, a special service pit and a vehicle wash. The servicing pit is used mainly for topping-up gearboxes and back axles and general greasing ofchassis, whilst there is also an air line laid on. The lead pipes from the oil and grease drums and air line are painted in different colours, according to the commodities they carry. This assists the operator in selecting the right gun without having to waste time in tracing the lead pipe -back to its source. The system can also be applied to electric installations in which there may be a number of different line voltages, or where there are differing characteristics in the supply.

A Modern Vehicle Wash

A-feature of the Southwell vehicle washer installed is the grille on which the vehicle stands. This grille, which lies flush with the floor, permits a vehicle to be washed down without the operator's having to paddle about in water and mud. A highpressure water system makes short work of long-standing deposits under mud wings and on wheels and chassis parts.

Also in this section I saw, a simple. form of ground anchor which any operator could quickly instal in his own service depot, It consists of two lengths of channel iron, arranged about an inch or so apart, cemenkted

flush into the floor. By providing suitable bars or chains having a pivoted T-end, it is possible to obtain enormous leverage without fear that the anchorage point will give way.

Another particularly serviceable appliance was a Weaver garage jack which had been converted to facilitate the removal or replacement of vehicle engines. It carr be used most effectivelyt. when the front member of the chassis is removable, as is the case With most Thornycroft models,

Useful Methanical Aids

A jack of similar type, but of lighter weight, is used to assist in the final removal of gearboxes when they have been released from the clutch housing and the propeller shaft. For removing cylinder heads, a hand-operated hoist is used. Again, this useful equipment has been adapted to serve this specific purpose.

Time-saving is a most important factor in any service depot, and when dealing with heavy components the practical answer lies in mechani c 11 handling. In the Thornycroft depot, for exenole, there is a Hughes gas-heated de-greasing plant located at one end of One of the long pits.

If an engine is to be de-greased, it is first drained and stripped of its external components and then picked up by a travelling hoist. The runway of the hoist covers the full length of the pit and ends at the a16 de-greaser, so that removal from the vehicle and transference to the degreaser becomes a co-ordinated straight-through operation.

An air line has many uses apart from tyre inflation, as in a machine shop components can be freed from swarf, as can the tools themselves. During assembly the parts can be kept clean, engine oilways can be blown through to remove possible obstructions, and many time-saving tools can be operated off a suitable supply of air under pressure.

Mr. Harrington told me that an item of equipment which he had found of great Use was a portable Morrisflex outfit. This comprises an electric motor driving a head through a length of flexible drive shaft.

There are numerous time-saving uses to which the Morrisflex can be put, from the removal of tenacious deposits, such as carbon, by means of wire brushes, to providing a useful source of power for small pieces of equipment which are normally manually operated.

Heating in workshops does not always receive proper attention. No .man can be expected to work properly if his hands be cold, and the maintenance of a comfortable temperature — about 65 degrees — throughout the building should be a primary consideration.

How this is to be accomplished will depend largely upon finance, but one of the most economical methods is by a hot-water system using either radiators or pipes. At the Thornycroft depot there is an oil-fired boiler of large capacity which supplies 38 radiators.

Firing and control of the boiler are entirely automatic, even to the starting and shutting-off times. Thermostats are responsible for con

trolling the heat, and Venner time switches look after the starting-up and closing:down of the oil burner.

Such a heating system would be outside the needs of the average operator, but the point is that naked sources of heat, such as coal or coke fires, gas and electric heaters, can be ruled out so far as the outer shops are concerned. The needs of most. operators would be served by a cokefired boiler with a system of hotwater. pipes. The boiler, of course, would be suitably isolated.

Although the practical Thornycroft machine-shop is equipped with a number of first-class tools, including lathes. millers, drills, an in-lin-9 borer, and so on; it is not intended that it should be run as a fully manned department. It does, however, fill the requirement of having available facilities for meeting emergencies.

In most instances an 8-in, lathe with, of course, a gap bed, a pillar drilling machine, a hack-saw machine, an in-line borer for main bearings and a connecting-rod borer should meet most needs in the way of heavy machines. The tools should preferably have individual motors, a system that avoids the use of overhead shafting, noisy belting and the need for having to place a machine in a position which may not be the most convenient.

The only feature which I have touched on directly affecting the amenities of the staff is that of heating, but according to the size of the undertaking, arrangements should be made for accommodating the men's clothes, preferably with means for drying them in wet weather. In the main depot of the Potteries Motor Traction Co., Ltd., a company that pays special regard to staff welfare, heated coat racks are providedfor this purpose