For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SRI-LUNGS is awarded each week to the sender of the best letter which we publish on this rage; all others are paid for at the rate of a penny a hue, with an allewarice for photographs, All notes are edited before boldly published. Mention your employer's name, in confidence, as evidence of good faith. Address, A, M. and F.,"The

' Commercial Motor," 7-15, Bosebery Avenue, _London, E.G. 1,

Lamps Alight. • • On Saturday, July 26th, light your lamps at 9.27 M London, 10.13 in Edinbaugh, 9.49 in Newcastle, 9.47 in Liverpool, 9.38 in Birmingham, 9.37 in Bristol, and 10-30 in Dublin.

A Simple Cylinder Lap.

The sender of the following communication has been awarded the Ws. prize this week.

11995] " H.J.0." (Battersea) writes :—" Some little time ago I was asked to inspect a motor lorry'which had been reported to be running.baclly. As a preliminary I just pulled over the starting handle to test the compression, and found that while on three of the cylinders it was good, there was no compression at all in the fourth. I ground in the valves of that cylinder,

.checked over the spaces between valves and tappets to make sure that each valvewas closing, and tried again. No improvement! The next thing obviously,

was to 'lift the cylinders, and this I did. Behold, when I-examined the piston of this particular cylinder, I found thatit could be shaken about quite freely within the cylinder. A closer examination showed that the Originating cause of the trouble was a breakage of the gudgeon pin. This had broken' clean through near one end, so that it was secured in the

boss of the piston itself onlyto, the extent of in

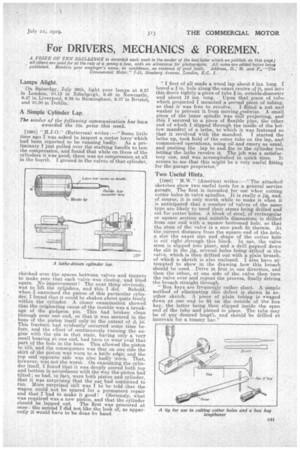

in'. This fracture, had evidently' occurred some time before, and the effect of continuously, running the engine with the pin in that state, having only a very small -bearing at one end, had been to wear oval that part of the hole in the boss. This allowed the piston to tilt; and the consequence was that on one side the skirt of the piston wax worn, to a. knife edge, and the top and opposite side was also badly worn. That, however, was not the worst. On examining the.cylinder itself, I found that it was deeply scored both top and bottom hi accordance with the way the piston had tilted ; so bad, in fact,Were both piston and cylinder, that it was surprising that the car‘ had continued to run. More .surprised still was I to be told .that the wagon could not be spared for a permanent repair and that I had to make it good I Obviously, what was required was a new piston, and that the cylinder should be lapped out. -The first was procured at once: the second I did not like the look of, as apparently it would have to be done by hand. "I first of all made a wood lap about 6 ins. long. I bored a gin, hole along the exact centre of it, and into this drove tightly a piece of tube I in. outsidediameter and about 12 ins. long. Upon that piece of tube which projected I mounted a second piece of tubing, so that it was free to revolve. I fitted a nut and" washer to prevent it from moving _endwise. A small piece of the inner spindle was still projecting, and this I secured to a piece of flexible pipe, the other end of which I slipped through the inside of the hollow mandrel of a lathe, to which it was fastened so that it revolved with the mandrel. I started the lathe up, took hold of the outer tube on the lap, and commenced operations, using oil and emery as usual, and pushing the lap to and fro in the cylinder but letting the lathe revolve it The job was a satisfactory one, and was accomplished in quick time. It occurs to me that this might be a very useful fitting . for the garage proprietor."

Two Useful Hints.

[1996] "M.." (America) writes : —" The attached sketches show two useful tools for a geiaeral service garage. The first is intended, for use when cutting cotter holes in valve spindles. It is really a jig, and, of course, it is only worth while to make it when it is anticipated that a number of valves of the same type a-re likely to need their stems being drilled and cut for cotter holes. A block of steel, .of rectangular or square section and suitable dimensions is drilled from one end with a square bottomed hole, so that the stem of the valve is a nice push fit therein. At the correct distance from the square end of the-hole, a slot the exact size and shape of the cotter hole is cut right „through this block. In use, the valve stem is slipped into place, and a drill popped down the slit in the jig, several holes being' drilled in the • valve, which is then drifted out with a plain breach, of which a sketch is also enclosed. I also have attempted to show in the drawing how this broach should be used. Drive in first in one direction, and then the other, at one side of the valve then turn the valve over and repeat the process, finally driving the broach straight through. "Box keys are frequently rather short. A simple method of eliminating this defect is shown in another sketch. A piece of plain tubing ia swaged down at one end to fit on the outside of the box key, the latter being then slipped inside the open end of the tube and pinned in place. The tube may be of any desired length, and should be drilled at intervals for a tOramy bar."