NEW PASSENGER CHASSIS

Page 20

Page 21

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

from the

COMMER WORKS.

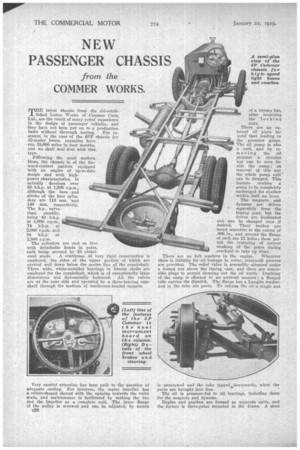

TMILE latest chassis from the old-estab1 fished Luton Works of Commer Cars, Ltd., are the result of many years' experience in the design of passenger vehicles, and they have not been put on to a production basis without thorough testing. For instance, in the ease of the 4PF chassis. for 32-seater buses, examples have run 38,000 miles in four months, and we shall deal first with this type.

Fallowing the most modern Ideas, the chassis is of the forward-control pattern equipped with an engine of up-to-date design and with highpower characteristics. It actually develops over 63 b.h.p. at 1,500 ramp., although the bore and stroke of the four cylinders are 110 mm. -rind 140 mm. respectively. The h.p. curve rises steadily, being 43 b.h.p. at 1,000 r.p.m., 74 b.h.p. at 2,000 r.p.m. and 84 b.h.p. at 2,500 r.p.m.

The cylinders are cast en bloc with detachable heads in pairs, each being secured by 10 nickel steel studs. A crankcase of very rigid construction is employed, the sides of the upper portion of which are carried well down below the centre line of the crankshaft. Three wide, white-metalled bearings in bronze shells are employed for the crankghaft„which is of exceptionally large dimensions and dynamically balanced. All the valves are at the near side and operated by a three-bearing camshaft through the medium 'of mushroom-headed tappets.

Very careful attention has been paid to the question of adequate cooling. For instance, the water impeller has a volute-shaped shroud with the opening towards the valve seats, and maintenance is facilitated by making the fan and the impeller as a complete unit. The inner flange of the pulley is screwed and can be adjusted, by means of a tommy bar, after loosening the locking nuts.

There are no external oil pipes beyond that leading to the pressure gauge. The oil pump is also a unit, and by removing the oil strainer a circular nut can be seen inside the sump ; on removal of this nut the whole pump unit' can be dropped. This feature enables a pump to be completely exchanged for another within half an hour.

The magneto and dynamo are driven separately from the timing gear, but the drives are duplicated and can be changed over if desired. Their bushes are bored eccentric to the extent of .006 in., and around the flange of each are 12 holes; these permit the restoring of correct meshing of the gears during overhaul to take up wear.

There are no felt washers in the engine. Wherever there is liability for oil leakage to occur, return-oil grooves are, provided. The relief valve is accessibly situated under a domed nut above the timing case, and there are removable plugs to permit cleaning out the oil ducts. -Draining of the sump is effected inan unusual manner ; a flanged tube carries the dipstiak. The flange has a Laugite washer, and in the tube are ports. To release the oil 'a single nut

is unscrewed and the tube tapped downwards, when the ports are brought into line. ?‘ The oil is pressure-fed to all bearings, including ,those for the magneto and dynamo. Engine and gearbox are formed as separate units, and -the former is three-point mounted in the frame. A steel !damping is utilized for the flywheel, which carries the separate outer member of the internal Cone clutch. This clutch has a single powerful spring, provision for the external adjustment of which is made by a circular nut, but this is a refinement which It is unnecessary to utilize in the ordinary course of running.

The suspension of the gearbox is from an arched 'channelsection cross-member at the front and a tabular crossmember at the'rear. The rear support actually takes the form of a bracket, with a centre bearing and a cap to carry the end of the gearbox. There is a large cover plate with an air vent, and at the near side is a long bracket projecting forward to carry the oil-filler cap, acCess to which can be obtained immediately through a body floorboard. Between the clutch awl the gearbox is a single fabric joint.

On a forward-control mediae the selector mechanism is often excessively complicated. In the Commer there is single-rod gear control and a selector cross-shaft on spherical bearings. Details of the gear can be seen in one of the drawing,e which we reproduce.

At the rear of the gearbox is a loco-type transmission

brake operated by hand. The shoes are centrally fulerummed to their carriers, which are compressed by face cams. The shoes are 41 ins, wide and lined with friction fabric.

Much interest attaches to the propeller shaft, as the front fabric joint of this has a special centring device which incorporates a safety feature in the form of a special outer spider, the boss of 'which surrounds the shaft, but does not touch it. If by any chance the joint gave, this spider carries the shaft, and with care a vehicle could actually be driven home. The propeller shaft ends in a torg,me tube ball, where there is a star-type joint which has scoops on the ends of the pins to take up oil from -the casing. The shaft itself is a 4-in.-diameter tube.

A steel pot-shaped casting, into which steel tubes are Pressed hydraulically and locked by right and left-hand nuts is utilized for the rear axle.

The long rear springs are overslung, and the springpad nuts are tightened from the top to avoid any risk of binding through possible rusting-in of the bolts. The springs themselves are of Woodhead make with integral clips. •

The axle is or the full-floating type, and the wheel hubs, both here and for the front axle, are mounted on Timken roller bearings. .

A single brake with large-diameter shoes acts on the rear-wheel drums, which are of east-steel. Front brakes of Clayton make, are employed, and these, with the rear brakes, are operated through a Dewandre servo. The side brake rods are carried in fibre guides to prevent whipping, and the brake cross-shaft is mounted in spherical bushes. We are glad to see That brake compensation is not considered necessary.

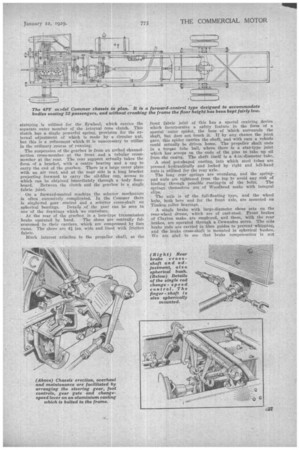

All the control gear, including the steering, is neatly arranged to form a unit, and on the steering column is mounted a compact instrument board. The dash is of steel, and in 'it is a hitand-miss ventilator. The main chassis details are as

— Gearbox ratios: top, direct ; third, 1.675 to 1;

second, 2.7 to 1; first, 4.441 to 1; standard worm-gear reduction, 5.2 to 1 for 32-in. by 6-in. or 34-in. by 7-in. tyres, but, if desired, 5,8 to 1 or 6.4 to 1 can be provided ; chassis weight (with oil, water and fuel), 2 tons 15 cwt.; turning circle, near side 60 ft., off side 62 ft. 6 ins.; wheelbase, 16 ft.; overall length, 24 ff. 7i ins.; track, front 5 ft. 8 ins., rear 5 ft. 4 ins.; frame height (loaded), 2 ft. 6" ins., which is considered sufficiently low.

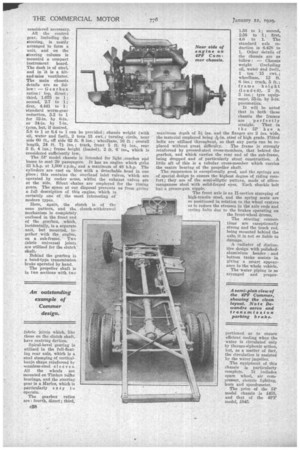

The 5P model chassis is intended for light , coaches and buses to seat 20 passengers. It has an engine which giv'es 33 b.h.p. at 1,500 r.p.m,„ and a maximum of 48 b.h.p. The cylinders are cast en bloc with a detachable head in one piece; this contains the overhead' inlet valves, which are operated by, rocker arms, whilst the exhaust valves are at the side. Silent chains are employed for the timing gears. The space at our disposal prevents us from giving a full description of this engine, which is certainly one of the most interesting of modern types.

Here, again, the clutch is of the cone pattern, and the clutch-withdrawal mechanism is completely enclosed in the front end of the gearbox, ,which, incidentally, is a separate unit, but mounted, together with the engine, on a sub-frame. Two fabric universal joints are utilized for the clutch shaft, Behind the gearbox is a band-type transmission brake operated by hand.

The propeller shaft is in two sections with two fabric joints which, like those on the clutch shaft, have centring devices.

Spiral-bevel gearing is utilized in the full-floating rear axle, which is a steel stamping of verticalbanjo shape reinforced by seamless-steel sleeve s. All the wheels are mounted on Timken rolltr bearings, and the steering gear is a Marles, which is particularly easy to operate.

The gearbox ratios are : fourth, direct ; third, standard axle reduction is 6.428 to 1. Other details of the chassis are as follow : — Chassis weight (including oil, water and fuel), 1 ton 15 cwt.; wheelbase, 12 ft. 6 ins.; track, 5 ft.; ' frame height (l oa de d), 2 ft. 3 ins. ; tyre equipment, 33-in. by 5-in. pneumatics.

It will be noted that in both these chassis the frames are perfectly straight. That in the 5P has a maximum depth of 5i ins. and the flanges are 2 ins, wide, the material employed being .in. steel of high grade. Fitted bolts are utilized throughout, so that any parts can be re

placed without great difficulty. The frame is strongly reinforced by pressed-steel cross-members, that behind the gearbox, and which carries the rear end of the sub-frame, being dropped and of particularly stout construction. A little aft of this is a tubular cross-member which carries the centre bearing a the propeller shaft.

The suspension is exceptionally good, and the springs are of special design to ensure the highest degree of riding comfort; they are of. the semi-elliptic pattern, made of silicomanganese steel with solid-forged eyes. Each shackle bolt has a grease-gun nipple.

The front axle is an H-section stamping of high-tensile steel, and the spring seats are so positioned in relation to the wheel centres as to reduce the stresses in the axle ends and spring bolts due to the brakes operating on the front-wheel drums.

The steering connections are exceptionally strong and the track rod, being mounted behind the axle, it is not so liable to damage.

A radiator of distinctive design with polishedaluminium header and bottom tanks assists in giving a smart appearance to the whole vehicle.

The water piping is so arranged and propor portioned as to ensure efficient cooling when the water is circulated only by thermo-siphonic action, but, as a matter of fact, the circulation is assisted by the water impeller. The equipment of this chassis is particularly complete. It includes spare wheel, air compressor, electric lighting, horn and speedometer.

The price of the 5? model chassis is £455, and that of the 4PP model, £845.