Brewery Fleet Costed Per Crate Carried

Page 42

Page 43

Page 44

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Taylor, Walker and Co., Ltd., is Building up its Own C-licence Fleet to Become Independent of Contract Haulage Services to the Greatest Possible Extent : Albion and Austin are to be the Company's Standard Makes of Vehicle

By Man Smith

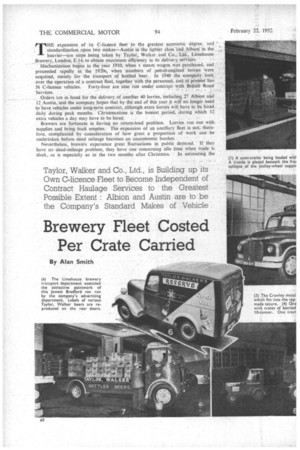

HE expansion of its C-licence fleet to the greatest economic degree, and standardization upon two makes—Austin in the lighter class. arid Albion in the heavier—are steps being taken by Taylor, Walker and Co., Ltd., Litnebouse Brewery, London, L.14, to obtain maximum efficiency in its delivery services. '

Meehanization began in the year 1910, when steam wagon was purchased, and proceeded rapidly in the 1920s, when numbers of petrol-engined lorries were acquired, mainly for the transport of bottled beer. In 1948 the 'company took over the operation of a contract fleet, together with the personnel and at .piesent has

56 C-licence vehicles. Foity-four are also run under contract with British Road Services.

Orders are in hand for the delivery of another 40 lorries, including 27 Albion and 12 Austin, and the company hopes that by the end of this year it will no longer need to have vehicles under long-term contract, although extra lorries will have to be hired daily during peak months. Christmastime is the busiest period, during which 12 extra vehicles a day may have to be hired.

Brewers are fortunate in having no return-load problem. Lorries run out with supplies and bring back empties. The expansion of an ancillary fleet is not, therefore, complicated by consideration of how great a proportion of work can be undertaken before dead mileage becomes an uneconomic burden.

Nevertheless, brewers experience great fluctuations in public demand. If they have no dead-mileage problem, they have one concerning idle time when trade is

slack,. as is especially so in the two months after Christmas. In estimating' the maximum economic size of a fleet, they have to determine the point at which overheads on vehicles idle in slack periods offset savings made by direct operation, compared with hiring during the busier months.

To obtain an accurate picture of transport economy, Taylor, Walker and Co., Ltd., keeps the most detailed costings. The Limehouse headquarters directly controls its own fleet, keeps check on the work of the fleets of the provincial depots, and is in close contact with the fleets of the subsidiary concerns of the group, some of which are the Cannon Brewery Co., Ltd., Curtis Distillery Co., Ltd., Victoria Wine Co., Ltd., Pelican Caterers, Ltd, Alperton Bottling Co., Ltd., and Bushell, ,Watk ins and Smith, Ltd., Westerharn, Kent. The transport activities of the Alperton Bottling Co., Ltd., were described in " The Commercial Motor" on August 3, 1951.

The Limehouse fleet serves 1,500 delivery points each week on regular runs in the London area and comprises 15 Albion rigid lorries, two Albion 10 ton tractors operated with six •Carrimore semi-trailers, two Austin 25-cwt. models and an Austin MO pick-up, apart from the contract vehicles---11 2-tonners, -nine 4-tonners, 15 6-tonners, five 7-tonners and two 10-tonners. To serve

outlying districts, bases are maintained at Hoddesdon. Hunton Bridge and Chelmsford. The articulated vehicles run feeder services between Limehouse and these depots, and two loads can betaken each day into Chelmsford, for instance, by one tractor operating with three semi-trailers. Hoddesdon has a fleet of six vehicles, Hunton Bridge nine and Chelmsford 10.

Limehouse also serves the Brighton area. Although the group has a brewery at Westerham, Kent, lying nearer to Brighton, account has to be taken of local public tastes, which make it necessary for Brighton to be supplied from Limehouse. London beers are sweeter than country brews, such as Westerham produces, and the Brighton trade is virtually an extension of that of the Metropolis.

Link with Uannon The Cannon Brewery at aerkenwell produces only draught beers, so deliveries of bottled beers are effected by Limehouse vehicles direct to Cannon houses. The Alperton Bottling Co., Ltd., concentrates on Guinness and delivers to all houses direct.

One of the distinctive features of the Alperton factory is the conveyor running under the arched loading bank on to which crates are unloaded. The vehicles based there have a quarter-circle cut-way at the rear, so that when they are backed against the bank, the conveyor is not impeded. (This was the subject of an illustration in the August 3 article.) To allow for the interchange of transport, when necessary, new vehicles now supplied to Limehouse also have this body contour.

The Limehouse brewery—the Barley Mow Brewery— is in two functional sections. Half is the brewing establishment and, on the ground floor of this building, beer is racked into barrels. The other half, comprising two buildings, is a bottling plant and is connected to the brewery section by pipelines. A given quantity of bottled beer requires approximately three times as much vehicle capacity as draught for its transport.

No Slackening in Demand A 6-tonner can carry 27 36-gallon barrels of draught beer, or 258 boxes each containing two-dozen I-pint bottles, the equivalent of 10i barrels. More people are turning from draught to bottled beer, and Taylor, Walker and Co., Ltd., finds that increasing demands are being made on its transport services. Although a large volume of the business in bottled beers has been taken over by the newly opened Alperton plant, there has been no diminution in the demands made upon the Limehouse bottling establishment.

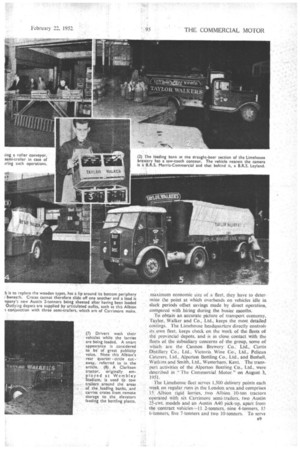

Of the two sections, that devoted to draught beer is the better laid out for transport working. The loading bank is open on each side of the building; lorries draw up on one side to unload and are loaded on the other side, where the bank has a saw-tooth contour.

Transport routine in the bottling section is more complicated, because of limitations of ground space. The main bottling building houses bottling units on floors one above the other and all output goes through a loading bank accommodating 17 vehicles. As this bank is not big enough to handle all dispatches, bays in the other bottling building are also used. A Clarkson tractor, originally employed at Wembley Stadium during the Olympic Games, ferries trailer-loads of crates to repair shops and stores.

At the side of the main building there are elevators, one for each bottling unit, which carry empty crates up to the appropriate storey. At ground level there is a large area around the elevators for crate storage, and vehicles usually unload there, but at slack periods all available spare space around the brewery is used for at 0 stacking crates, and vehicles unload wherever necessary. The Clarkson tractor finds further employment in bringing remotely stacked crates to the elevators.

Inside the bottling plant there is a mechanized conveyor system for moving crates from the units to the stock rooms and thence to the ground-floor dispatch bays. Lansing-Bagnall battery-electric trucks are used on the banks to assist in the collation of the loads. Large numbers of crates are stored internally and thought has been given to saving floor space by employing fork-lift trucks for higher stacking. The variety in the sizes of crates, however, is considered to make the use of pallets impracticable.

The old wooden boxes are being replaced by Crawley metal crates which when stacked form a rigid formation. The bases of these containers halm lips which fit into the tops, so that, unlike the wooden crates, they cannot slide off one another.

Disposal of Yeast Besides the company's transport for the delivery of its products, the road haulage activities ancillary to brewing are interesting. Hops are carried from outside cold stores and warehouses to the brewery in the company's vehicles. The malted barley from the maltsters is delivered by road and after extraction the spent grain is chuted into lorries to be taken away for making cattle food. Yeast used for fermenting the wort (the liquid extract from the malt) grows during the brewing process, the surplus' being carried away by road to make a wellknown brand of yeast extract.

Taylor, Walker and Co., Ltd., regards its vehicles as good publicity media and particular attention is paid to their appearance. When the Alperton fleet was built up, vans were chosen because of the greater amount of body space available for carrying coloured advertisements. Platform lorries, with Dekaloy flooring, are preferred at Limehouse, and the bodybuilders, R. G. Hodges and Co., Rainham, Kent, provide detachable skirt panels which present a neat appearance and afford space for the slogan "For the Best Bottled Beers."

During loading, the driver washes his vehicle. The other members of the crew, the drayman and the trouncer, attend to loading. The drayman is responsible for checking in full beers and return empties collected on delivery rounds. Trouncers, or labourers, are carried on all vehicles of 3-ton payload and over. The dispatch department has a system by means of which each load is checked three times.

Running Repairs

Besides necessitating a smooth-working operational routine, space limitations demand that a great deal of maintenance work be put out. During slack trade periods, vehicles are put in for major overhauls, but running maintenance can be carried out with the com pany's own facilities. Minor repairs are effected at once, and one man attends to tyre pressures and battery and oil levels. Much of the body repainting and signwriting is done on the premises, and routine service work is undertaken at week-ends. Stores of vehicle spares are recorded by the Kalamazoo system.

The exhaustive costing system was devised by the transport manager, Mr. A. C. Earle. Separate accounts are kept for vehicles run under C-licence, contract and normal hiring arrangements. Day-to-day figures arecollated monthly and monthly figures annually in a detailed schedule in which costs are worked out to a sum per crate carried. Mr. Earle showed me this schedule, and I noted that the costs for C-licence, contract and other hired vehicles worked out in the approximate ratio of 7: 8: 9.

Account is taken in the costing headings of bonuses paid to transport and yard staff, including Christmas gifts, besides the usual items—licence, fuel, insurance, and so on. Vehicles are depreciated over live years. Record is kept of daily hours Worked against the total possible and adjustments are made in the figures for tonnages dealt with to accord with part consignments of bottled beer carried on lorries handling mainly draught, and vice versa. Mileage run by contract lorries in excess of the agreed distance is also checked. Most of the contract vehicles are Leylands.

The vehicles operating from Limehouse have a total tonnage capacity of 307 and each year carry well over 90,000 tons of bottled and draught beer, bottled forming about three-quarters of the aggregate tonnage. The company's own fleet covers about 340,000 miles a year, the 22 Litnehouse vehicles being responsible for 125,000 miles and the 10 Chelmsford-based lorries 100,600 miles. in the year ended May, 1951, the 44 B.R.S. contract vehicles, which have a total payload capacity of 203 tons, ran over 400,000 miles.

Fuel-consumption rates of different vehicles are note

worthy. Six Albion 6-ton oilers average 14.5 m.p.g. and seven 4-tonners of the same make 18 m.p.g. The figure for the Albion 10 ton articulated vehicles is 13.5 m.p.g. A difference appears with some Albion petrol-engined 6-toriners, numberi.of--wl*h on country work return 8 m.ps and others on town deliveries 6.5 m.p.g. Vehicles are mainly running in the London area in heavy traffic, and the country vehicles are subject to many delivery stops. Austin vehicles in the fleet show 25.5 m.p.g. for an A40 pick-up and 15 m.p.g. for the 25-cwt. models. Of• the 12 A ustins.on. order, 10 are 2-tonners. -Some similar vehicles already operating show an average of 10 m.p.g.

Mr. Earle looks forward to the time when outstanding vehicle orders are fulfilled. By undertaking delivery services with •a modern fleet of selected types, he is confident that substantial savings can be made. Looking farther into the future, he hopes that licences will be granted for the erection of new buildings at Limehouse that will ease some of the difficulties in transport operation caused by the layout of buildings put up some 70 years ago.