For your part, keep it clean

Page 69

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

It takes only one piece of grit to wreck a rebuilt engine, writes Richard Longworth. Somewhere between a strip and rebuild, there must be an effective cleaning process

• It is said that cleanliness is next to godliness, and this is particularly true where machinery is being rebuilt. Working machinery always brings dirt and filth into the workshop, but it only takes one piece of grit to wreck a rebuilt engine and cost a lot of money. Somewhere between strip and rebuild, there must be an effective cleaning process.

There are many different ways of cleaning a part back to the metal, but they nearly all start with a basic degreasing process. Only after a rudimentary cleaning can a part be passed with confidence to either the scrap bin, or for further service.

One of the largest suppliers of degreasing machinery to British workshops is Safety-Kleen UK, a subsidiary of SafetyKleen Corporation of America. One factor that makes these machines popular is that Safety-Kleen supplies a complete service rather than hardware.

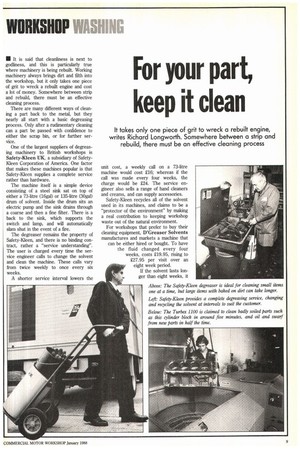

The machine itself is a simple device consisting of a steel sink sat on top of either a 73-litre (16gal) or 135-litre (30gal) drum of solvent. Inside the drum sits an electric pump and the sink drains through a coarse and then a fine filter. There is a back to the sink, which supports the switch and lamp, and will automatically slam shut in the event of a fire.

The degreaser remains the property of Safety-Kleen, and there is no binding contract, rather a "service understanding". The user is charged every time the service engineer calls to change the solvent and clean the machine. These calls vary from twice weekly to once every six weeks.

A shorter service interval lowers the unit cost, a weekly call on a 73-litre machine would cost £16; whereas if the call was made every four weeks, the charge would be £24. The service engineer also sells a range of hand cleaners and creams, and can supply accessories.

Safety-Kleen recycles all of the solvent used in its machines, and claims to be a "protector of the environment" by making a real contribution to keeping workshop waste out of the natural environment.

For workshops that prefer to buy their cleaning equipment, D'Greaser Solvents manufactures and markets a machine that can be either hired or bought. To have the fluid changed every four weeks, costs 219.95, rising to £27.95 per visit over an eight week period.

If the solvent lasts longer than eight weeks, it becomes more economical to buy the machine, which costs £230 for the standard model, the larger version costing £285. The drums of solvent still come on an exchange basis, and cost £27.95.

Degreasing machines such as those already described are only really efficient for cleaning small items, such as parts being stripped out of an engine that is being overhauled.

Large items are best cleaned by a different type of machine which uses hot water under pressure as a cleaning medium, with a small proportion of rust inhibitor. Although these cleaners are more expensive, for a workshop with a high throughput, one could supply clean parts without tying up skilled labour.

The Ardrox Rotajet range of machines are claimed to be able to degrease, derust, strip paint and decarbonise. The smallest machine is the 1)24, which is 82cm square, and 115cm high, weighs 227kg, and will clean 90kg at a time. The 3kW heaters use either electricity or gas, and have a sump filled with 45 litres of solvent.

The Ardrox machines are not available for hire, and the D24 costs £1,988 if heated by electricity, and 22,698 if it uses gas. There are four more models in the range, the 1)40, D60, D80 and D108, which has a load capacity of 1,360kg.

The D60, which will clean 454kg at a time, costs £7,197 heated electrically, and £8,521 using gas. The machines are built for Ardrox by Oaldiffe Engineering in Yorkshire, and Ardrox which has recently merged with Pyrene Chemicals will supply cleaning chemicals, but cannot dispose of used material.

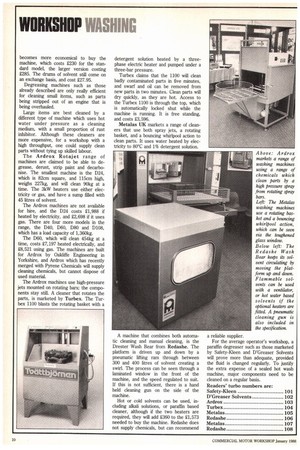

The Ardrox machines use high-pressure jets mounted on rotating bars; the components stay still. A cleaner that rotates the parts, is marketed by Turbex. The Turbex 1100 blasts the rotating basket with a detergent solution heated by a threephase electric heater and pumped under a three-bar pressure.

Turbex claims that the 1100 will clean badly contaminated parts in five minutes, and swarf and oil can be removed from new parts in two minutes. Clean parts will dry quickly, as they are hot. Access to the Turbex 1100 is through the top, which is automatically locked shut while the machine is running. It is free standing, and costs £3,596.

Metalas UK markets a range of cleaners that use both spray jets, a rotating basket, and a bouncing whirlpool action to clean parts. It uses water heated by electricity to 80°C and 1% detergent solution.

A machine that combines both automatic cleaning and manual cleaning, is the Drester Wash Bear from Redashe. The platform is driven up and down by a pneumatic lifting ram through between 300 and 400 litres of solvent creating a swirl. The process can be seen through a laminated window in the front of the machine, and the speed regulated to suit. If this is not sufficient, there is a hand held cleaning gun on the side of the machine.

Hot or cold solvents can be used, including alkali solutions, or paraffin based cleaner, although if the two heaters are required, they will add £360 to the £1,573 needed to buy the machine. Redashe does not supply chemicals, but can recommend a reliable supplier.

For the average operator's workshop, a paraffin degreaser such as those marketed by Safety-Kleen and D'Greaser Solvents will prove more than adequate, provided the fluid is changed regularly. To justify the extra expense of a sealed hot wash machine, major components need to be