MAKING BEST USE OF THE FORD.

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which will Appeal to the Owner, Driver and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck, we endeavour to deal with the subject from every viewpoint, so that the advice will appeal to the owner, driver, maintenance engineer or mechanic.

We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for any which are published.

372.—Preventing Side Play in the Brake Cams.

Examination of many vehicles will show that at the points where the brake cams pass through their bushes in the axle flanges pronounced signs of wear will be seen if the vehicles have

much mileage to their credit. In addition to wear in the brake-cans bush, a slot may have been cut in both bush and flange through side pressure of the cam.

This may have two results. In the first place, it may be found impossible to fit a new bush, which will remain fast in positioh once braking stresses are applied, as there will be little support left for this bush.

The second result is sometimes somewhat embarrassing, for if the slot which has been cut in the flange is sufficiently deep the cam may lodge there, and sudden application of the hand lever to draw the clutch into neutral sometimes has the effect that the lever remains fast and the clutch can only be released by pressure on the clutch pedal. It can easily be understood how awkward this may prove in traffic.

The trouble can be prevented, either as a permanent or temporary expedient, by fitting an end stop to the earnoperating shaft. This can be done by bolting a piece of flat mild steel, suitably bent, to the lower anchorage of the radius rod, the plate pressing against the end of the cam spindle.

00

373.—Facilitating Reversing.

Many drivers, when reversing, are in the habit of doing so with the hand lever holding the clutch in the neutral position, the advantage of this proceeding to them being that they have one foot free to apply to the foot brake when it would otherwise be required to hold the clutch pedal in the neutral position.

The actual point of travel on the hand-lever quadrant at which thd clutch is brought into neutral without applying the brakes of the rear wheels may not be easily determined, but a very effective expedient, which at the same time secures a positive neutral, may be employed.

Observe the line of travel of the clutch-lever screw, and draw the hand lever back until the clutch has been brought into neutral without application of the hand brake. This can easily be determined by jacking up the rear axle and watching the rear wheels. They will have a tendency to spin, and to ensure that the clutch is really disengaged, apply the foot brake to arrest the wheels.

Having ascertained the exact point on the speed lever, mark it and drill a countersink to receive the point of the clutch-lever screw. As the hand lever is now being drawn into the neutral position, the clutch-lever screw will find its way into the depression which has been made by the countersink, and will arrest further movement in a way which will be sufficiently noticeable to the operator to let him know that the neutral position has been secured.

This small refinement will be found a great convenience, as it will act as an additional check to prevent the clutch slipping into engagement when the ratchet of the hand lever is not very effective, as is sometimes the case.

374.—Replacing Ford Springs.

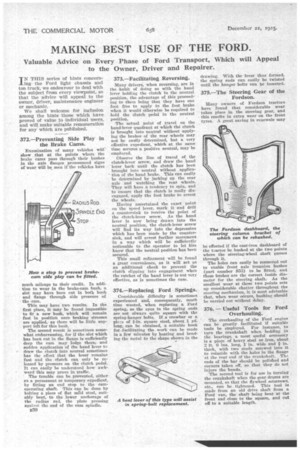

Considerable difficulty is sometimes experienced and, consequently, much time wasted, when replacing a Ford spring, as the eyes in the spring ends are not always quite square with the spring-hanger bolts. If a crowbar or a pieca of t-in. square steel, about 1 long, can be obtained, a suitable hook for facilitating the work can be made in a few minutes by heating and bending the metal to the shape shown in the drawing. With the lever thus formed, the spring ends can easily be twisted until the hanger bolts can be inserted.

375.—The Steering Gear of the Fordson.

Many owners of Fordson tractors have found that considerable wear takes place in the steering gear, and this results in extra wear on the front tyres. A great saving in renewals may

be effected if the east-iron dashboard of the tatetor be bushed at the two points where the steering-wheel shaft passes through it.

The holes can easily be reamered out to enable front axle trunnion bushes (part number sm) to be fitted, and these bushes are the correct inside diameter for the steering shaft. As the smallest wear at these two points sets up considerable chatter throughout the steering mechanism, it is most advisable that, when wear occurs, bushing should be carried out without delay.

376. Useful TQOIS for Ford Overhauling.

The overhauling of the Ford engine can be greatly facilitated if suitable tools be employed. For instance, to turn the crankshaft when bedding in the bearings. a most useful accessory is a piece of heavy steel or iron, about 2 ft. 6 ins. long, 1 in. wide and

thick, with two studs screwed into it to coincide with the holes in the flange at the rear end of the crankshaft. The ends of the bar should be polished and corners taken off, so that they do not injure the hands. The second tool is for use in turning . the crankshaft when the gear drums are mounted, so that the flywheel setscrews, etc., can be tightened. This tool is made from an old drive shaft from a Ford van, the shaft being bent at the front end close to the square, and cut off to a suitable length.