CUSTOMER'S CHOICE

Page 34

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

Some recent examples of purpose-built bodywork, new methods and materials

BETWEEN the exotic one-off special body and the production jobs which are as alike as two peas lies a broad band of purpose-built bodywork whose design is an amalgam of the experience of bodybuilder, operator, and supplier. Very often the particular requirements of a single operator lead to features which are taken up by many customers; sometimes the changing demands of a particular trade or industry lead a wide awake bodybuilder to produce a new model which meets virtually all the operational points but which can be offered at much_ .reduced .cost through the economies of a wider market.

The incentive to produce capacious vehicles capable of being driven without an hgv licence has led to a host of under-3-tons-unladen trucks. One of the more interesting is a light alloy van with glassfibre roof and marine ply floor, plus full-depth roller shutter, produced by R. Partridge (Cassington) Ltd to meet the special needs of Langlow Products Ltd, Chesham, Bucks.

Langlow needed a roomy van to carry 45ga1 drums of oil and solvent, but it also wanted a better handling system than the practice of rolling drums off the tailboard to drop on a pile of old tyres, which some distributors use. The answer was a lightweight boxvan with a 5cwt-capacity Ratcliff hydraulic tail-lift having a 2ft-square platform.

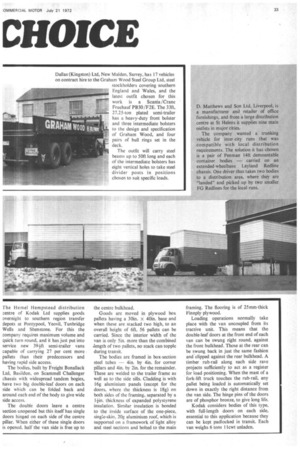

One man can now deliver the full drums without assistance, and Langlow reckons that the vehicle will save the company £1000 a year on transport costs. The chassis is a Commer VC5. Dallas (Kingston) Ltd, New Malden, Surrey, has 17 vehicles on contract hire to the Graham Wood Steel Group Ltd, steel stockholders covering southern England and 'Wales, and the latest outfit chosen for this work is a Scania /Crane Fruehauf PB30 /F2E. The 33ft, 27.25-ton plated semi-trailer has a heavy-duty front bolster and three intermediate bolsters to the design and specification of Graham Wood, and four pairs of bull rings set in the deck.

The outfit will carry steel beams up to 50ft long and each of the intermediate bolsters has eight vertical holes to take steel divider posts in positions chosen to suit specific loads.

The Hemel Hempstead distribution centre of Kodak Ltd supplies goods overnight to southern region transfer depots at Pontypool, Yeovil, Tunbridge Wells and Shenstone. For this the company requires maximum volume and quick turn-round, and it has just put into service new 394ft semi-trailer vans capable of carrying 27 per cent more pallets than their predecessors and having rapid side access.

The bodies, built by Freight Bonallack Ltd, Basildon, on Scammell Challenger chassis with widespread tandem bogies, have two big double-leaf doors on each side which can be folded back and around each end of the body to give wide side access.

The double doors leave a centre section unopened but this itself has single doors hinged on each side of the centre pillar. When either of these single doors is opened, half the van side is free up to the centre bulkhead.

Goods are moved in plywood box pallets having a 30in. X 40in. base and when these are stacked two high, to an overall height of 6f1, 56 pallets can be carried. Since the interior width of the van is only 5in, more than the combined .length of two pallets, no stack can topple during transit.

The bodies are framed in box-section steel tubes -4in. by 4in. for corner pillars and 4in. by 2in. for the remainder. These are welded to the trailer frame as well as to the side sills. Cladding is with 16g aluminium panels (except for the doors, where the thickness is 18g) on both sides of the framing, separated by a 1+in. thickness of expanded polystyrene insulation. Similar insulation is bonded to the inside surface of the one-piece, sing:e-skin, 20g aluminium roof, which is supported on a framework of light alloy and steel sections and bolted to the main framing. The flooring is of 25mm-thick Finnply plywood.

Loading operations normally take place with the van uncoupled from its tractive unit. This means that the double-leaf doors at the front end of each van can be swung right round, against the front bulkhead. Those at the rear can be swung back in just the same fashion and clipped against the rear bulkhead. A timber rub-rail along each side rave projects sufficiently to act as a register for load positioning. When the mast of a fork-lift truck touches the rub-rail, any pallet being loaded is automatically set down in exactly the right distance from the van side. The hinge pins of the doors are of phosphor bronze, to give long life.

Kodak considers bodies of this type, with full-length doors on each side, essential to this application because they can be kept padlocked in transit. Each van weighs 6 tons 1lcwt unladen. Although the inside is completely sealed — allowing it to be steam cleaned without risk to the lin.-thick polystyrene insulation — only the floor panel is moulded in situ. The sidewalls, roof panel and front bulkhead are of premoulded flat grp sheet, bonded to the orthodox alloy frame of the body.

Extending the floor moulding (which incorporates a non-slip filler) about lin. up the body sides seals the bottom corners; vertical corner joints and those around the roof panel are sealed with a moulded fillet of grp material.

External panelling is in alloy sheet, finished in Buswers characteristic varnished grey livery. A pair of narrow double doors which can be swung open within the width of the vehicle are fitted to the 32in.-wide rear doorway.

Instead of conventional channel-section cross-bearers, Barham has designed an all-welded base frame of lin.-square steel tube. Because of its shallow depth, floor height of the Buswell van has been kept down to only 284-in. unladen — on its Ford Transit 115 chassis. Overall length of the body is 9ft, while interior height is just 6ft. Unladen weight of the complete (petrol-engined) van is 1 ton 84-cwt.

Meat products from Buswell's main depot at Blisworth, near Northampton, are delivered to shops and supermarkets, using the new vans.

Long experience of supplying vehicles overseas gave Telehoist Ltd, Cheltenham, an advantage when asked to supply 12 special bodies on Bedford KELC5 chassis for Bangladesh. The main requirement was for the urgent movement of food supplies, but the vehicles had to be basically versatile.

The design solution was a 16ft by 7ft body with 3ft bin.-high removable stake sides, with a tailgate hinged in two sections for quick and easy loading. The stake sides are in three sections, thus adding to the versatility of the bodies. A dump truck manufactured by Decauville SA, France, uses a new British material that offers scope for payload increases and longer life. This is Nicuage Type I high yield structural steel in plate form fin. to -tin, thick. The Ni Cu-Nb steel was developed by International Nickel and supplied in slab form by Brown Bayley, of Sheffield, but Redheugh Iron and Steel Co Ltd, of Gateshead, is the first British company to commercially roll this type of steel in plate.

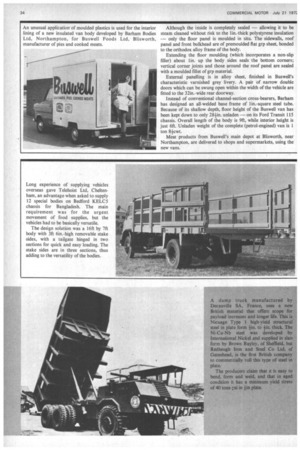

The producers claim that it is easy to bend. form and weld, and that in aged condition it has a minimum yield stress of 40 tons psi in +in plate. Blue Rosette Transport Ltd has just filled a requirement for 26 mediumtemperature refrigerated vehicles for delivering bacon, pies and other meat products, specifying Commer Walk-Thru KC 40 chassis-cabs of 10ft 3M. wheelbase on which are mounted Robert B. Massey bodies using a new type of construction. The ,vans are all under 3 tons unladen.

Massey's new structure is a combination of "all-plastics" and light-alloy-framed techniques, using double aluminium frames embedded between two grp skins so that interior and exterior are smooth. The object is to avoid some of the problems of all-plastics bodies — eg delamination between the glassfibre casing and the insulation.

The new bodies use the alloy framing as the stressed structure and they are built from flat slabs rather than by the one-piece-moulded method. This, says Massey, makes smaller production runs economic.

Interior racks are in galvanized mesh on aluminium framing, refrigeration is by holdover plates, and there is a Frigidaire compressor in the cab. Unladen weight is 2 tons 17ewt and payload I ton 18cwt.

Being able to offer bulk transport facilities while retaining the ability to carry other than bulk goods is essential for the husiness of the Hay and Straw Attency (Berkshire) Ltd. Crowthorne. Agriculture's transport requirements alter with the seasons, and this has led he company to specify a modified form of c.ontajfief in ordering a Tamplin belt discharge unit.

Mounted on is Ford DT 1417 chassis, it is a 950 cu ft model with extra wide 20in.) conveyor belt, and can discharge its load in less than I 01T1111, but the principal variation is that the container has double rear doors so that it can be used to cm.r.i, bagged foodstuffs.

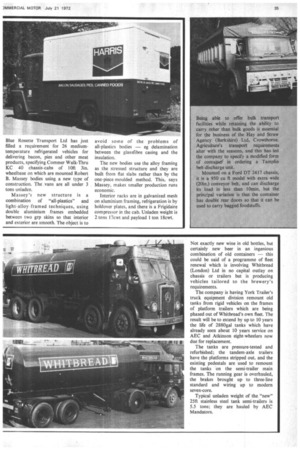

Not exactly new wine in old bottles, but certainly new beer in an ingenious combination of old containers — this could be said of a programme of fleet renewal which is involving Whitbread (London) Ltd in no capital outlay on chassis or trailers but is producing vehicles tailored to the brewery's requirements.

The company is having York Trailer's truck equipment division remount old tanks from rigid vehicles on the frames of platform trailers which are being phased out of Whitbread's own fleet. The result will be to extend by up to ICI years the life of 2880ga1 tanks which have already seen about 10 years service on AEC and Atkinson eight-wheelers now due for replacement.

The tanks are pressure-tested and refurbished; the tandem-axle trailers have the platforms stripped out, and the existing pedestals are used to remount the tanks 'on the semi-trailer main frames. The running gear is overhauled, the brakes brought up to three-line standard and wiring up to modern seven-core.

Typical unladen weight of the, "new" 25ft stainless steel tank semi-trailers is 5.5 tons; they are hauled by AEC Mandators.