• If this week's test truck looks familiar then don't

Page 65

Page 66

Page 67

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

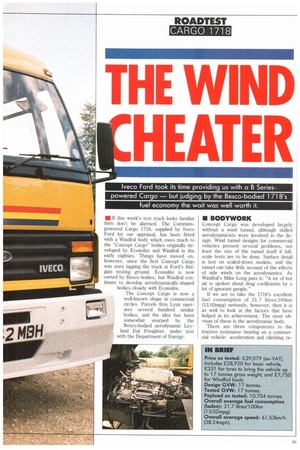

be alarmed. The Cumminspowered Cargo 1718, supplied by lveco Ford for our appraisal, has been fitted with a Windfoil body which owes much to the "Concept Cargo" bodies originally developed by Econolite and Windfoil in the early eighties. Things have moved on, however, since the first Concept Cargo was seen lapping the track at Ford's Belgian testing ground. Econolite is now owned by Besco bodies, but Windfoil continues to develop aerodynamically-shaped bodies closely with Econolite.

The Concept Cargo is now a well-known shape in commercial circles. Parcels firm Lynx operates several hundred similar bodies, and the idea has been somewhat usurped by the Besco-bodied aerodynamic Leyland Daf Freighter, under test with the Department of Energy.

• BODYWORK

Concept Cargo was developed largely without a wind tunnel, although skilled aerodynamicists were involved in the design. Wind tunnel designs for commercial vehicles present several problems, not least the size of the tunnel itself if fullscale tests are to be done. Surface detail is lost on scaled-down models, and the tunnel can take little account of the effects of side winds on the aerodynamics. As Windfoil's Mike Long puts it: "A lot of hot air is spoken about drag coefficients by a lot of ignorant people."

If we are to take the 1718's excellent fuel consumption of 21.7 litres/100km (13.02mpg) seriously, however, then it is as well to look at the factors that have helped in its achievement. The most obvious of these is the aerodynamic body.

There are three components to the tractive resistance bearing on a commercial vehicle: acceleration and climbing re sistance, rolling resistance, and aerodynamic drag.

With a four-wheeled truck on a typical distribution route, the largest component of total tractive resistance is the rolling resistance. Drag and acceleration are about equal, and are smaller contributors.

Reducing drag, therefore, can have only a limited effect on the fuel consumption of the truck. Estimates vary according to the type of vehicle and the type of terrain, but a 30% reduction in drag could be expected to gain fuel savings of around 3% for a 38-tonner on a hilly motorway, and around 8.5% for a light van on the same route. A four-wheeler 17-tonner might reasonably be expected to gain economy somewhere between the two extremes.

The Concept Cargo has a drag coefficient (CD) figure of around 0.5, which is around 30% better than many other 17tonners fitted with the most rudimentary aerodynamic aids. Coincidentally, this is also the percentage reduction in drag that one would expect to gain by running as the third vehicle in a convoy of similarlysized trucks at 80kin/h (50mph).

Lacking a convenient convoy of trucks for every trip, most of us have to make do with aerodynamic advantages, and this is where the Cargo's bodywork comes in. As might be expected, the areas of highest air pressure on a travelling truck like a box-bodied Cargo are the front of the cab and the front of the exposed box body. Considerable turbulence is created by the gap between the cab and the body, and there is also a certain amount of turbulence at the rear of the body.

The Cargo 1718 has had much work done on filling the gap between the cab and the body with spoilers and extra panels. There is a deep front spoiler and side skirts to prevent air getting underneath the non-aerodynamic chassis, and at the back there is a false collar to retain the air flow right to the rear of the body.

While the Cargo's angular cab may not be expected to give the best aerodynamic properties, with a large box body there is little to be gained by smoothing off the lines of the cab, which merely throws the air onto the even more angular box body. With a flat bed body, however, there would be considerable gains from a smooth cab shape. So the imposing Cargo's body might gain an operator anywhere between 3% and 8.5% in fuel economy. But are there any other reasons for running such a vehicle — after all, such vehicles don't come cheap. Good aerodynamics can reduce spray from a vehicle, and can reduce the soiling in winter months, but another important reason is the visual impact of the body on the streets.

Does the Windfoil/Econolite body succeed in this respect? You will have to judge for yourself, but with HRH Prince Charles conducting a skirmishing war with designers and architects at the moment, we think he might approve of the functionalist aims of the Concept Cargo.

• DRIVELINE

The Cummins-powered Cargo 17-tonner was introduced at the Motor Show last September. By the end of August this year. over 237 units had been registered. and the vehicle is firmly aimed at the largest sector of the 17-tonne market.

The range comes -with a spread of engine power from 97kW to 211kW (130280hp). There are wheelbases between 3.52m and 6.2m, and a host of gearbox options. Our test vehicle is powered by the Cummins 6BTA 5.9-litre diesel. It is an inlet-charge-cooled unit, giving 1271(W (170hp) at 2,500rpm, and 602Nm (444Ib ft) at 1,500rpm. The cylinder block is of an advanced design, which has a liner-less construction, and the oil and water pumps, oil cooler mounting, oil filter head and alternator mountings are cast integrally with the block.

In spite of the unit's relatively high power, there is space in the chassis to allow the Cargo's floor to slope down sufficiently at the front to give the crosscab access so essential for multi-drop delivery work.

The gearbox is Eaton's popular 4106 unit, fast becoming essential for 17tanners in search of a gearbox. It has six speeds, all with synchromesh, and a direct top gear. This takes the drive to a conventional propellor shaft leading to a Rockwell rear axle.

The addition of a sleeper cab to the vehicle adds 21,530 (ex-VAT) to the price, and there are a number of other extras on the specification which takes the basic price of 228,920 (ex-VAT) to a cool 239,079 (ex-VAT) for the whole shooting match.

The "17-tonne" Cargos are in fact 16,800kg Cargos, which need the optional extra of wheels and tyres uprated to take the gross weight to 17 tonnes. Apparently, some operators take the lower weight vehicles as the special wheels and tyres only add some 200kg to the Cargo's gross weight. As tested, the payload is 10.704 tonnes, although the body/payload allowance is 12.377 tonnes, which compares well with the equivalent figure of 11.830 tonnes for the similarly-powered Mercedes-Benz 1617 and 12.417 tonnes for the AWD TL 17-18 tested recently.

• PERFORMANCE

The first part of our Welsh route test is a long haul down the motorway to the Severn Bridge. The Cargo ate this up without any risk of fuel consumption penalties. Whether this was due to the Windfoil body is difficult to tell. There was a slight breeze bearing on the front threequarters of the truck, but 96km/h (60mph) was easily attained and maintained.

There was little wind noise in the cab, and the engine seemed well damped. lyeco Ford claims a drive-by noise level of 83dB(A) for the Cummins-powered vehicle and the engine certainly seemed quiet when outside the cab. The dual carriageway journey up to Hereford was equally pleasant and unstrained. With the gearlever in sixth position the Cargo ground its way up to the gentle slopes of the A449, albeit rather slowly at times.

Once on the A-roads and during the journey back towards Oxford, the aerodynamics stopped playing their part in the fuel consumption equation and the performance. The Cummins engine needs revving to persuade it to climb hills. It is a mistake to let the rev counter flutter down towards the bottom end of the green sector at 1,600rpm, because the engine will bog down and die. Six speeds, we feel, are too few for arduous A-road deliveries in 17-tonners. lveco Ford will, however, be announcing a nine-speed gearbox for the Cargo in time for the Scottish Motor Show this autumn. The gearchange quality on the Cargo is one of the best we have come across with the Eaton 4106 box. This is due partly to the excellent needle-roller bearings in the gear lever from the box to the cab, and partly to well thought-out engineering. Cargos have suffered premature failure of those needle-roller bearings in the past because of their proximity to the exhaust manifolding and turbocharger. We don't know if this problem has yet been solved, but the gear linkage does run over the top of the turbocharger in this truck as well.

The final fuel consumption figure of 21.7 lit/100km, boosted by the excellent motorway consumption of 21.95 lit/100km (12.87mpg), help propel the Windfoilbodied Cargo to the top of our fuel consumption chart for 17-tonners. The question has to be asked about that body, and what the performance of other trucks like the Mercedes would be with similar aerodynamics? It certainly helped the Cargo achieve these excellent fuel figures, but the Cummins engine looks fairly frugal as well. The difficulty is telling just how frugal.

• HANDLING

In general parabolic springs need more damping because they don't have the internal damping characteristics of a multileaf semi-elliptic spring. Iveco Ford's engineers were clearly exhausted after designing such a good gear-change system, as they have woefully mismanaged the front axle damping.

Admittedly the ride quality is reasonably good on medium-grade roads, hut when

the roads become bumpy, the truck starts to "float'', a most unpleasant sensation. In addition, the 1718 rolls noticeably on even the mildest of corners.

The Cargo's brakes are also affected by the inadequate damping of the front axle's parabolic springs. At 64km/h the front axle started to vibrate strongly as the wheels bounced under hard test braking. The overall braking distances are none too impressive either, and we feel there is considerable room for improvement.

By contrast, the steering weight is just right at all speeds, and the wheel is just the right size to get a good purchase without dominating the cab, as it does on a Mercedes-Benz.

• INTERIOR

By far and away the most outstanding aspect of the Cargo's interior is its seating. Having tested a succession of trucks with seats which could be improved by being replaced by a soap box, it was real pleasure to drive the Cargo. Th mechanical springing is just right, an there are small side supports that are hi enough to prevent the driver slipping o the seat when cornering, but not too bi to prevent an easy exit from the se when delivering. lveco Ford (or For more rightly) has always prided itself o trimming seats in-house at Langley, move we would recommend to certai other mass producers of 17-tonne trucks.

The sleeping part of the cab is too basi for more than the occasional night oui There is a thin, sparse mattrest rudimentary curtains and little else.

Like most 17-tonner Cargos we hay come across, the instrumentation an switchgear is of a high order. Easy t read and use, the plastics and desig show other manufacturers the way horn in practicality.

One addition to the standard Cargo ii tenor trim was a Mitsubishi televisic monitor, mounted on the centre conso with a small rear-view camera above tlrear door. The system costs betwee £800 and £900, and takes around half day to fit. The television monitor is autt matically switched on when reverse gei is selected. The driver is provided with view of the scene behind the truck up 15m away. Reversing is a cinch with tf system on, and we managed to get tlCargo within 100mm of the kerb. At tf moment, it is being sold to local autho ities for dustbin lorries, where there al workers around the back of the vehiclt Mitsubishi Electric hopes to get the syl tem into more haulage fleets soon.

The floor of the cab is covered in nil ber mats and, although we would haN preferred a little less exposed paintworl the whole interior should be easy to cleal

• SUMMARY

Aerodynamic trucks usually come with high price, a lot of hassle for the drive and debatable gains. The Concept Car design shows that efficient shapes neE not cost the earth. We did find that all if daily checks for the Cargo are hidde away under hatches, but apart from th there are no problems with the system.

The remaining question concerns if benefits of the aerodynamics in econom■ How would a base-model vehicle have dor against the Concept Cargo, we wonder?

Apart from that the Iveco Ford Carp range is as efficient as ever. The Cun mins B Series engines seem to suit if Eaton gearbox, and their installation in a Cargo is as good as any we have see' Our main concern remains with th springing, or more particularly the dam] ing on the vehicle. Always a compromis between the laden and unladen conditim the suspension on the Cargo seems to over-biased towards the part-laden. Stiff damping would help to allay our concern. El by Andrew English.