ROLLER BEARING SPRINGS.

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

A Striking New American Development. By Henry Sturniey.

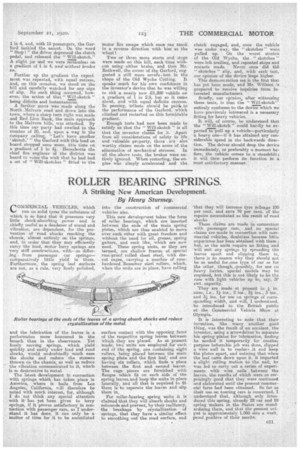

COMMERCIAL VEHICLES, which run on solid tyrea the substance of which is so hard that it possesses very little shock-absorbing power . and is chiefly useful as a deadener of sound and vibration, are dependent, for the prevention of road shocks reaching the chassis, almost entirelyon the springs, and, in order that they may efficiently carry the: load, motor lorry springs are very stiff constructions, with—as differing from passenger car springs— comparatively little . yield in them. Furthermore, the spring leaf surfaces ere not, as a rule, very finely polished, and the lubrication of the leaires is a performahce more honoured in the breach than in the observance. Yet freely moving springs, which yield quickly and easily under load and road shocks, would undoubtedly much ease the shocks and reduce the stresses thrown on the chassis, as well as reduce the vibration communicated to it, which is so destructive to metal.

The latest development in connection with springs which, has taken place in America, where it hails from Los Angeles, California, will therefore be noted with much interest, for, although I do not think any special attention with it has yet been given to lorry springs, if it proves satisfactory in connection with passenger cars, as I understand it has done, it can only be a matter of time for it to be assimilated into the construction of commercial vehicles This new development takes the form of roller bearings, which are inserted between the ends of the main spring plates, which are thus enabled to move over each other with great freedom and without the need for oil, grease, spring gaiters, and such like, which are now used. These spring units., as they are termed, are shallow frames of special rust-proof rolled sheet steel, with diecut cages, carrying a number of casehardened Bessemer steel rollers, which, when the units are in place, have rolling

surface contact with the opposing faces of t'he. respective spring leaves between whieh they are placed. As at present made, two units are employed for each end of the spring, one containing eight rollers, being placed between the main spring plate and the first leaf, and one having six rollers, which finds a place between the first and, seemed leaves. The cage pieces are furnished with flanges -which fit on each side of the spring leaves, and keep the units in place laterally, and allthat is required to fit them is to separate the leaves and slip them in

For roller-bearing spring units it is claimed that they will absorb shocks and rebounds and prevent, by their resiliency, the breakage by crystallization of springs, that they have a similar effect to smoothing out the road surface, and

*that they will increase tyre mileage 100 per cent, and save 70 per cent, or the repairs necessitated as the result of road shooks

These claims are made in connection with passenger cars, and no special

• claims are made in connection with commercial vehicles, doubtless because little experience has been abtained with them ; but, as the units require no fitting and

suit any springs by spreading the leaves apart and slipping them in, there is no reason why they should not be as useful for-aerie type of car as for the other, though, possibly, for .useon heavy lorries, special models may be required, but this is not likely to be the case With light vehicles up to, say, 31' cwt. capacity.

-They are made at present in L. in, sizes, i.e., 14ins., 2 ins., ins., 3 Ma, and 31 ins. for use en springs of corresponding width, and will, I understand, be introduced to the British public at the Commercial Vehicle Show at Olympia.

It is interesting to note that their invention, like many another good thing, was the result of an accident, the inventor, using a screwdriver'to separate his spring plates for lubrication, finding he needed it temporarily for another purpose beforedas job was done, slipped a wire nail in to replace at and keep the plates apart, and noticing that when the leaf came down upon it, it imparted a slight rolling motion to the nail, he was led to carry out a series of experiments with wire nails between the leaves, the results of which were so surprisingly good that they were continued and elaborated until the present commercial form had been obtained. So far as their use on touring cars is concerned, I understand that, although, only introduced this spring, already 23 car and 10 spring makers in the States are standardizing them, and that the present output is approximately 1,000 sets a week, proof positive of their merits.