Patents Completed.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Lubricating Laminated Springs. Sparking Plug Construction, A Plate Clutch. Preliminary Heating of Fuel.

Copies of complete specifications of the patents published on this page can be obtained from the Sales Branch, Patent Office, Holborn, W.C., at the cost of sixpence for eackspecification.

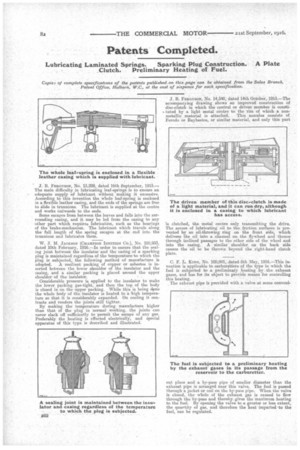

J. B. FERGUSON, No. 13,228, dated 16th September, 1915.— The main difficulty in lubricating leaf-springs is to ensure an adequate supply of lubricant, without making it excessive. According to this invention the whole leaf-spring is enclosed in a flexible leather casing, and the ends of the springs are free to slide in trunnions. The lubricant is supplied at the centre and works outwa.rda to the ends.

Some escapes from between the leaves and falls into the surrounding casing, and it may be led from the casing to any other part which requires lubrication, such as the bearings of the brake-mechanism. The lubricant, which travels along the full length of the spring escapes at the end into the trunnions and lubricates them.

W. J. M. JACKSON (CHAMPION IGNITION Co.), No. 100,933, dated 10th February, 1916.—In order to ensure that the sealing joint between the insulator and the easing of a sparking plug is maintained regardless of the temperature to which the plug is subjected, the following method of mannfacture is adopted. A resilient packing of topper or asbestos is inserted between the lower shoulder of the insulator and the easing, and a similar packing is placed around the upper shoulder of the insulator.

Considerable pressure is applied to the insulator to make the lower packing gas-tight, and then the top of the body is closed in on the tipper packing. While this is being dyne the whole body of the insulator is heated to a high temperature so that it is considerably expanded. On cooling it contracts and renders the joints still tighter. By making the temperature during manufacture higher than that of the plug in normal working, the joints can never slack off sufficiently to permit the escape of any gas. Preferably the heating is effected electrically, and special apparatus of this type is described and illustrated. J. B. Fzu.onsoic, No. 14,540, dated 14th October, 1915.--The acoompanyiug drawing shows an improved construction of disc-clutch in which the central or driven member is constituted by a light metal centre to the rim of which a non metallic material is attached. This annulus consists of Ferodo or Raybestos, or similar material, and only this part

is clutched, the metal centre only transmitting the drive. The access of lubricating oil to the friction surfaces is prevented by an oil.throwing ring on the front side, which delivers the oil into a channel on the flywheel and thence through inclined passages to the other aide of the wheel and into the casing. A similar shoulder on the back aide causes the oil to be thrown beyond the right-hand clutch plate.

C. F. L. KING, No. 100,991, dated 8th May, 1916.—This invention is applicable to carburetters of the type in which the fuel is subjected to a preliminary heating by the exhaust gases, and has for its object to provide means for controlling this heating. The exhaust pipe is provided with a valve at some conveni ant place and a by-pass pipe of smaller diameter than the exhaust pipe is arranged near this valve. The fuel is passed through a jacket or coil on the by-pass pipe. When the valve is closed, the Whole of the exhaust gas is caused to flow through the by-pass and thereby gives the maximum heating to the fuel. By opening the valve to a greater or less extent, the quantity of gas, and therefore the heat imparted to the fuel, can be regulated.