THE MOTOR SHOVI FROM OUR ANGLE

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

HALF.-DAY devoted to intensive

examination, from; the commer

cial-vehicle angle, of the exhibits at the Motor Show, now being held at Earls Court, London, revealed few points in respect of which the car designer can teach engineers in our industry. Moreover, in many ences where an advanced practice is employed, its object is to attain an end that is of greater importance in car usage than under the conditions of commercial-vehicle operation.

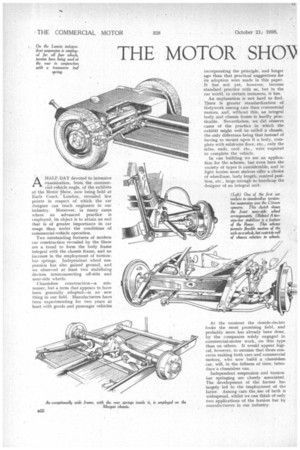

Two outstanding features of modern car construction revealed by the Show are a trend to form the body frame integral with the chassis frame, and an increase in the employment of torsionbar springs. Independent wheel suspension has also gained ground, and we observed at least two stabilizing devices interconnecting off-side and near-side wheels.

Chassisless construction—a misnomer, but a term that appears to have been generally adopted—is no new thing in our field. Manufacturers have been experimenting for two years at least with goods and passenger vehicles incorporating the principle, and longer ago than that practical suggestions for its adoption were made in this paper. It has not yet, however, become standard practice with us, but in the car world, in certain instances, it has.

An explanation is not hard to find. There is greater standardization of bodywork among cars than commercial motors, and, without this, an integral body and chassis frame is hardly practicable. Nevertheless, we did observe cases of the practice in which the exhibit might well be called a chassis, the only difference being that instead of having to mount upon it a body, complete with subframe floor, etc., only the sides, ends, roof, etc., were required to complete the vehicle.

In van building we see an application for the scheme, but even here the variety of types is considerable, and in light lorries most Makers offer a choice of wheelbase, body length, control position, etc., large enough to handicap the .designer of an integral unit.

At the moment the double-decker looks the most promising field, and probably more has already been done, by the companies solely engaged in commercial-motor work, on this type than on others. It would appear logical, however, to surmise that those concerns making both cars and commercial motors, who now build a chassisless car, will, in the fullness of time, introduce a chassisless van.

Independent suspension and torsion. bar springing are closely associated. The development of the former has largely led to the employment of the latter. Among cars the.usc of both is widespread, whilst we can think of only two applications of the torsion bar by manufacturers in our industry. Tgese, however, are enough to prove that the system is not only satisfactory. but also affords smoother riding than the conventional laminated spring.

With a big and fairly constant sprung weight, suspension problems are easier than when the relation of sprung and unsprung weight is low. Accordingly, the car designer has the harder task; moreover, to him smooth riding is of greater importance. Hence the wider use of torsion bars on cars.

Then there is the question of expense. %Ve were informed, however, on the Hotchkiss stand at Earls Court that a torsion bar costs only 15s. 6d.

Whether there be any real need for independent suspension is, in our opinion, a little doubtful. Certainly it must diminish tyre wear slightly and enhance road-holding and comfort; and our impressions of the Bedford van, which has torsion-bar independent suspension of the front wheels, were very favourable.

Nevertheless, there is little the matter in these respects with commercial vehicles following orthodox practice, and only where there is some further object to serve, such as increased up. and-down movement of the wheels for cross-country work, or an unusual chassis layout with other advantages, as on the Tilling-Stevens Successor and Yeoman models, can we see much prospect for independent suspension on commercial vehicles.

Stabilizers, or anti-roll devices of the torsion-bar type, feature on two makes of car, the Humber and the Rover. They are quite simple, comprising transverse bars, forming cross-shafts, coupled at their ends to the axles, so that upward motion of one wheel tends to twist the bar and raise the other wheel.

One disadvantage of utilizing soft springs to give smooth riding is that they allow the body to sway out, under the influence of centrifugal force, when cornering. Vehicles employed for the transport of light, fragile goods need softish springs, and there seems scope here for following the lead of the car designer.

In view of the simplicity and, probably, low cost of these devices we foresee their adoption to a moderate extent for light and medium-weight vans.

We observed an increase in frontwheel-drive cars. The merits are local

ization of mechanism at the front, and the freedom to bring an uninterrupted floor down to little more than a few inches above ground level. Apart from freak-hill climbing, the. wheel-spin tendency is of negligible consequence.

For buses both attractions are considerable, and although the lower power-to-weight ratio of the bus, as compared with the car, is off-set by the reduced gear ratio, we do not think the greater proneness of the front wheels to spin would prohibit its adoption. Again, however, arises the question of whether there is a real commercial demand.

Oil-engined cars we did not see in the Motor Show. We understood, however, that there would be on view a petrol injection pump. Learning that this was a Scintilla product, we pene trated into the fastnesses of the accessory section, but only to find that it had not yet arrived. (Doubtless it has since turned up.) However, its application opens up an interesting avenue for consideration.

Injection of petrol dispenses with a carburetter, only air needing to be induced into the cylinders. Ignition is, of course, still by spark. Compression. ignition would need pressures prohibitive, because of detonation. One of the objects of petrol injection is to ensure an equal charge to every cylinder. It supercharging be used, injection of the fuel cuts out carburation difficulties which might otherwise arise.

If control be by quality instead of quantity, as on oil engines, efficiency shbuld be higher, because the compression does not diminish as when a throttle valve is partially closed. 1Veak mixture no longer constitutes a source of trouble through burned valves, etc., as is proved by modern economical petrol engines, running on the leanest mixture practicable and having widegap plugs. Steliked valves and seatings, etc. The Vauxhall and Bedford engines are examples.

There might, perhaps, be difficulties with the lubrication of the injectionpump plungeM and sleeves, but no doubt these could be overcome, if necessary, by mixing lubricant with the petrol. , It is only to be expected that supercharging should make more headway among car users than commercial-motor operators, because it may still be regarded as in the nature of a luxury rather than a necessity. There ie, at Earls Court, a number of cars equipped with superchargers as standard, notable among these being the A.C., Graham and Mercedes-Benz.

V-type engines seem to have gained more ground with the private motorist than the goods or passenger-vehicle operator. Horizontally opposed units, however, show no signs of becoming more popular, whilst at the Commercial Motor Show, last year, there was evidence of good prospects for this type. We believe the Jowett four-cylinder car is the only representative of a flatengined vehicle at the Motor Show, but we saw a " tlat-five " Coventry-Victor engine, and a Meadows pancake unit in the motor-boat section, which looked easily adaptable for vehicle usage.

Helical Springs for Suspension.

Besides its supercharger, the Mercedes-Benz, referred to above, has many other points of interest to the commercial-motor engineer. Suspension at back and front is by large helical springs—certainly a novelty. They should be as efficient as torsion bars, but are not so neat. The transmission and final-drive gear are sprung, cardan shafts transmitting torque to the rear wheels. The frame is a welded job of oval-section tube—an example of splendid workmanship. Gauze-covered ventilators are fitted into the brake backplates.

Another Mercedes-Benz looks •much more like a commercial vehicle than a car. It is the colonial model with fourwheel steering and drive, which, of course, has for years been used in our field, notably on the Latil forestry tractor.

Miscellaneous details that attracted our eye as of interest to the operator include an increasing use of central chassis lubricators; the introduction by the Hardy Spicer concern of a rubbertype universal joint for application where there is only small axial movement; the popularity of paddle-boxenclosed rear wheels, such as the Morris van has had for some years; door handles on the Opel which require the same action to release the catch as to pull open the door, and on the same make grab handles on the backs of the front seats to help up the passengers in the rear seats (an obvious lesson from the coach or bus); an increased number of box-section frames, and the placing of rear road springs inside the frame.