Two New Mann Steam Lorries.

Page 4

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

One to Work Under the Traction-engine Law, and One for Fire-extinguishing.

When the Heavy Motorcar Order, 1904 (regulating the tare and axle-weights of motor vehicles) came into force, it was generally believed that it sounded the death-knell of all lorries having a capacity greater than 6 tons. Many manufacturers found some difficulty in producing a vehicle of even that capacity without, in some way, coming dangerously near the limits of the Act. At the time that the Order was issued, the regulation of the axle-weight was favourably received by the makers, who, however, took exception to the clause which stated that the total or loaded weight of a vehicle, in running order, should not exceed 12 tons. This limitation has, undoubtedly, Had an adverse effect on the design and capabilities of the heavier wagons. We believe that, had the axle-weight only been the subject of regulation, the order would have given more universal satisfaction, and we should have seen a greater advance in the evolution of this useful type of machine.

Yielding to a demand for a vehicle capable of taking a load of 7 tons on its own platform even if it became necessary to work it under the traction-engine law—Mann's Steam Cart and Wagon Company, Limited, of Pepper Road Works, IIunslet, Leeds, succeeded in producing such a machine. An example of this type of wagon is illustrated on page 267, and it is one of two supplied to Wm. Hancock and Company, Limited, of The Brewery, Cardiff. The latter company deserves the thanks of the whole commercial motor industry for the staunch and liberal support which it has given to heavy motor vehicles. At all shows where steam wagons are included in, the exhibits, one is almost sure to find a machine that has been built for this well-known Cardiff brewery.

The makers of the vehicle, at present under notice, not pretend that it comes under.the Motor Car Acts as regards weight, although, in other respects, the machine is within the requirements of the regulations. It is necessary, therefore, that the user of such a wagon should take out a traction-engine license, costing .4;.to, in order to legalise its use on the public highway. Under certain conditions, the additional load which may be carried would soon compensate for the extra annual expense for the license.

The general design of the new model which has been produced at the Hunslet Works, follows closely that of the same company's " 5-tormer," to which we have referred on many occasions, the most recent Of which was on page

234 ante. The " 7-tonner " is, however, much larger and is more powerfully constructed; it is not by any means modified " 5-tonner." The engine dimensions of the

latter model have been increased from 4i and 61 inches to 5 and 8 inches in the diameters of the high and low-pressure cylinders respectively for the 7-ton vehicle, and the pistonstroke has been increased from 7 to 8 inches. Such an increase in dimensions necessitated, of course, increased facilities for steam raising; the boiler was, therefore, made larger, and its working pressure was raised to 200I15. per square inch in consequence. Both the engine and the twospeed gear, which, by the way, gives speeds of 2 and 5

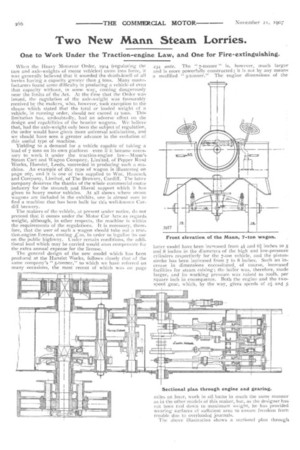

Sectional plan through engine and gearing.

miles an hour, work in oil baths in much the same manner as in the other models of this maker, but, as the designer has not been tied down to maximum weight, he has provided wearing surfaces of sufficient area to ensure freedom from trouble due to overloaded journals.

The above illustration shows a sectional plan through

the engine and driving gear, from which it will be seen that the cylinders are bolted on to a stout cross-plate coming between the main frame plates of the engine. The forward one of the two oil-baths contains the engine, crankshaft, and first motion gear-wheel and pinion. The other oil-bath contains the change-speed pinion (which comes between the second and third-motion shaft) and the main, driving gear to the hind axle, as well as the differential gear. The new oil is usually put into the engine oil-bath, which contains the quick-running parts, and any oil escaping from the same along the second motion shaft is collected in the after oil-bath; and, as the wheels contained in this are slow running, it is not so essential that the oil should be absolutely free from dirt. Nearly all the bearings have sealed or closed ends, to prevent any oil from escaping.

The second motion shaft revolves when the engine is " out of gear," and consequently, the slow-driven pump, which is worked by an eccentric cm the end of it, can be used when the wagon is standing. Reversing is effected by the company's patent, single-eccentric reversing gear, and slide valves are used in both cylinders. The change-speed pinions, which are shown out of gear, slide upon a square, and are work.ed by one lever (not shown), which comes outside the oil-bath. It will be noticed that the brackets for all four of the shafts have turned projections on them, which fit into large holes bored in the frame plates. This relieves the bolts from the strain of the gearing, and makes a thoroughly rigid job, as all the shafts are tied together by the same The steering-gear is arranged so that a duplicate wheel (see front view), can be put on the far side of the boiler ; this permits the attendant to relieve the driver, by sometimes steering the vehicle on the road. In order to accommodate the extra load, the platform is of large size and is no less than 17 feet long by 7 feet 3 inches wide. The overall dimensions of the wagon are : length, 24 feet, and width, 7 feet 3 inches. The driving wheels of this mammoth steam lorry are built of steel and are 4 feet in diameter by 14 inches wide. The water tank has a capacity of 200 gallons, but, with this tank and the bodee empty, with no fuel in the bunkers or in the fire-box, and no load on the platform, the vehicle weighs about 7 tons. The wagon is capable of taking 7 tons on its own platform, but, we are informed, some

lorries of this model are frequently used for loads exceeding that amount, and, in a few cases, no less than 8 tons have been carried on the wagon platform. We look forward, with interest, to the time when figures will be available which will show the cost of working a steam wagon of so large a l' cm ti'.

Fire-extinguishing and Fumigation.

A steam wagon for an extremely interesting type of service is another of the recent manufactures of this company. This vehicle, which we illustrate on this page, has been designed for export to Alexandria, where it will be used to extinguish fires, or to carry out disinfection in the holds ot ships, or in warehouses, by the sulphur dioxide process. In addition to this more ordinary purpose, it can be used to ex_ terminate rats and other vermin, where there is a suspicion of the plague, or where a vessel comes from one of the plague ports.

The fire engine which generates carbon dioxide under pressure, and diseharges this, mixed with water, on to the seat of the fire, is certainly an advance on the crude though common method of drowning a fire with water. As a rule, both of these methods do practically as much harm to the things one is attempting to save as the fire would have done, and, in a case of fire in the hold of a ship, the water may not only ruin the cargo, but endanger the ship's safety. A .third process of fire extinguishing depends upon the use of a gas only, and, for various reasons, Sulphur dioxide is the most suitable for the purpose : this process is used in the machine under discussion.

The complete apparatus consists of a Clayton; extinguishing and disinfecting machine, which is mounted on a standard, 2-ton, Mann, steam wagon. The extinguishing portion of the mechanism comprises : a chamber in which sulphur is burnt; and a steam-driven blower, by means of which the resulting gas is circulated through the compartment of the hold in which the fire is present. The gas is forced into the. lower part of the affected compartment under the pressure of the blower, and is withdrawn from the upper part, the circulation being continued until the proportion of gas thoughout the compartment is so high as to extinguish the fire, and until sufficient time has elapsed for it to penetrate into the very heart of the cargo in a way that would be impossible with water. A series of " headers " will be noted at the base of the apparatus; these are part of -a special cooler through which the gases pass during the period of their circulation, in order that the temperature in the hold may be reduced below the point at which combustion might again occur, when the sulphur dioxide gas is replaced by air ; this, of course, is a very important feature. The only alterations in the wagon itself are : the ordinary, lorry platform has been replaced by special brackets which carry the extinguishing machine; hinged platforms have been arranged for the attendant; and a special cock has been fitted to provide steam for the blower from the wagon boiler. The compact construction of the 2-ton wagon makes it particularly suitable for the work it is called upon to do in this -connection, as it will be obvious that the machine must get to its work under all circumstances, and very often through restricted avenues and confined situations. For use abroad; the locomotive boiler and straight-forward, compound engine are distinct advantages, as they are understood by any qualified engineer. In view of the heat of the climate, steel road wheels have been fitted.