Kom Drivers &Mechanics

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send us an account of any special incident of your work or ex,herience. If suitable, we will edit your votes, sutfily a sketch when required, and pay you for everything published. Mention your employer's name, in confidence, as evidence of good faith. Address to The Editor, THE COMMERCIAL MOTOR, Rosebery Avenue, London, E.C.

Light Up Your Lamps At 8.50 on Thursday ; 8.51 on Friday ; 8.53 on Saturday ; 8 58 on Monday ; 8.58 on Tuesday ; 8.59 on Wednesday.

Try This Instead of a Pit.

7'1ce sender of the following communication has been awarded the 10e. prize this week.

[1500J "RT. "(Bedford fill) writs :—" I am enclosing a sketch [We have had this redrawn.—En.] and description of a special inspection platform which may possibly be appreciated by the proprietors of

garages, as well as drivers and mechanics in general. Readers of the 'D. and M.' pages who have had the job of taking down gearboxes, base chambers a:nd other parts of a car know how difficult and uncomfortable it is to work in a pit.

" The platform is made of timber, and is so designed as to take to pieces readily for re-erection in other places. To give it stability the wooden uprights are braced by adjustable tie-rods, and if found necessary tie-rods can also be placed across the ends, but I have found it quite sufficient to mortise-in a stout beam at each end, held, of course, by strong bolts.

"To enable the car to run up on the platform, runners are provided, which hook on to one end of it. Bath the runners and the platform itself are provided with side flanges, to prevent any possibility of the ear being driven over or slipping over the side. By the use of this construction, free access to the whole of the under side of the chassis is obtained without the slightest inconvenience. Having used one for a long time I can testify asto the comfortable working conditions obtainable by its use. 'The platform can, of course, be altered to suit special requirements. For instance, if it be found necessary, a bench and vice can be fitted up beneath the platform and attached to it, so that work can he conducted on the spot, without having to run to and fro between the car and the fitting-shop bench.

E2

Anether advantage which is obtained by the use of an overhead construction like this is that there is no danger of workers' being overcome by the fumes of waste petrol which are often present at the bottom of pits. In most pits the floor usually becomes a congealed mass of mud and grease, and it is a difficult matter to keep them thoroughly clean.'

A Neat Gearwheel Repair.

[1501] " D.F.J." (Edinburgh) writes :—" I am employed in a company which owns a number of buses. During a very busy part of the season, one of these buses mid to be withdrawn from service because of a detect in the gearbox. On making an examination I found that the teeth on the first-speed pinion of the sliding sleeve had stripped, and as the first and second-speed pinions were in one piece, it seemed as if it would be essential to obtain a complete new set.

"It would have taken some time to get it from the manufacturers, and as the bus was wanted for immediate service, I decided to endeavour to fit another pinion by splicing it to the undamaged part. This pinion I obtained from a similar sleeve in which the teeth had stripped off the second-speed gear, leaving the one which was requireu in fairly good condition.

"To start with I softened the two sets and cut off the damaged portion of each, leaving Ili in. more than the original length of the sleeve to allow for the making of a double-check dog-joint. "After placing the -two serviceable parts on the square shaft upon which the sleeve slides, I laid this shaft, on a surface-plate, and scribed off the parts of each pinion which would have to be cut up to form the joint. Then, by the judicious use of the hacksaw, drill and file, I cut away the superfluous metal in such a manner, that the dogs in onepinion would fit into recesses in the other.

"It will thus be seen that, when the repaired sleeve is on its shaft, the two pinions are effectively locked together, the shaft acting as a key. It was necessary that a double-cheek joint should be formed, as the sleeve has to be moved by a change-speed fork, which acts on a collar fixed to the second-speed pinion, and, of course, the fork has to move in both directions." Oil and Sawdust Will Clean Your Hands.

L1502] "H.A.S." (Westeliff) writes : —"During many years' experience as a mechanic and driver, I have endeavoured to find methods of getting dirt and oil off my hands as quickly as possible, and a few tips on the subject may be of interest to those of your readers who are employed in occupations where they come in contact with oil and dirt.

" The method which I have found very useful is to use a small quantity of lubricating oil to soften the skin, and to mix with this a little sawdust. After rubbing the hands well together, a small quantity of petrol on a rag should be used to rennae the oil. This, should be followed by a wash with ordinary soap and sawdust, or, if preferred, powdered soap and sae dust will remove almost all traces of dirt.

The hands should never be dipped into petrol, as this only drives the dirt further into the skin. It should always be applied in small quantities on a rag, and simply.used for wiping off the dirt."

How to Remove Wheels and Pinions from Shafts.

1.1503] " J.C.H." (Eastville) writes :—" In every garage it is necessary at some time or other to remove wheels, pinions and suchlike from their shafts, and at times great trouble is experienced during this work when the parts are rusted together, or have been designed with a small-angle taper.

In manv cases manutacturers make the ends of the shafts slightly rounded. This of course, is good design and workmanship, but often causes trouble 'when removing parts from the shaft, as the removing tool slips on the rounded end and .sometimes ruins some of the threads. Should there be a centre left in the shaft, a pointed screw is sometimes used with the removing dogs. This, however, is very bad practice, for centres should be left severely alone, as, if the shaft is to be put into the lathe at any time to be treed up, the centres may be all out of position, and it is also possible to split the thread by using a pointed screw.

After experiencing much trouble, I made a small block, of which T enclose a sketch [We have had this redrawn.—En.]; this entirely obviates the difficulty of removing parts from shafts. It is made from a short piece of round steel, each face being slightly undercut.

" If, as it is in many cases, the wheel puller is made up of old bits of plate and bolts which are found in every engineering. shop, the value of the device is even greater, as A, is never possible to put exactly even pressure on the end of the shaft, and this little fitment adjusts itself and prevents pressing the shaft to one, side. it also has not the spreading action which sometimes occurs when a pointed screw is used.

" It will be found that about three sizes will be quite enough to cover all classes of work from a read wheel to a magneto or pump driving-wheel.

"A few days ago I had to deal with a number of engines having timing wheels of very light design, and the camshaft taper being very slow and the pinions being held on by large nuts, these were often pulled up much too tightly, making it a very difficult matter to remove the wheels, and in doing so some of them were considerably damaged. Up to that time the withdrawal-cramp used for removing the pinions had only two arms, and I found that a great improvement was effected by increasing the number to three, as this prevented the wheels from being put out of truth.

' With road wheels it may be found difficult to use a three-armed cramp, but in cases like these the arms need not be equally spaced. This would, of course, not be worth while doing for a small number of wheels, but if the cramp is in. constant use, it would be advantageous. " Another point I should like to mention is that the arms of the cramp should be secured to it by means of bolts of small diameter ; by doing this they will constitute a kind of safety valve against damage being done to either the wheel or the axle by pressure which may be too great."

How to Enlarge the Bore of Case-hardened Parts.

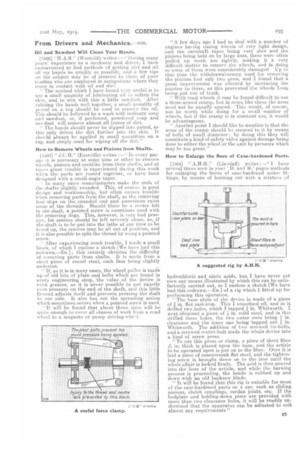

[1504] "A.11.11." (Llardell) writes :—" I have several times seen in your 'D, and M.' pages methods for enlarging the bores of case-hardened motor fittings, by means of burning out with a mixture of

hydrochloric and nitric acids, but I have never yet seen any means illustrated by which this can be satisfactorily carried' out, so I enclose a sketch [We have had this redrawn.—En.1 of a rig which I fitted up for performing this operation.

" The base plate of the device is made of a piece of in, flat cast-iron. This I smoothed off, and in it drilled two holes, which I tapped a in. Whitworth. I next obtained a piece of in. mild steel, and in this drilled three holes, the two outer ones being tin. clearance and the inner one being tapped out a in. Whitworth. The addition of two screwed tie-bolts, and a screwed centre-bolt made the whole device into a kind of screw press.

"To use this press or clamp, a piece of sheet fibre -A. in, thick is placed upon the base, and the article to be operated upon is put on to the fibre. Over it is laid a piece of countersunk flat steel, and the tightening screw is brought down on to the iron until the whole affair is locked firmly. The acid is then poured into the bore of the article, and while the burning process is proceeding, the inside is rubbed up and down with an old hacksaw blade.

" It will be found that this rig is suitable for most of the ease-hardened parts on a car, such as sliding pinions, clutch couplings, Garden joints, etc. If the bedplate and holding-down piece are provided with more than two clearance holes, it will be readily understood that the apparatus can he adiusted to suit almost any requirements"