The Andover

Page 24

Page 26

Page 27

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

connection

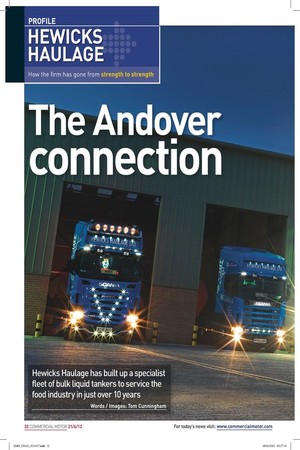

Hewicks Haulage has built up a specialist fleet of bulk liquid tankers to service the food industry in just over 10 years

Words / Images: Tom Cunningham CM is confused as to why a fledgling bulk liquids firm would choose a remote location in Suffolk to base its operations. After all, it’s hardly close to any of the country’s manufacturing powerhouses or bulk liquid storage facilities, is it? But the more Carl Brinkley, one of the Hewicks Haulage directors, explained the firm’s cargo, the more it started to sound like an agricultural movement specialist: as the answers came, it began to make a lot more sense.

“Hewicks is heavily involved in the collection and delivery of food co-product for the animal feed industry; namely milk, the residue from the brewing industry and molasses,” he told us. “Dairy product manufacturing is all around us – there’s a huge sugar beat processing factory just up the road at Bury St Edmunds and the entire county has always had strong links with brewing; directly or indirectly,” he continued. Add the fact that Felixstowe is 20 minutes up the road, and it all points towards a geographical location derived more from judgement than luck.

The relationship between the owners and the people who run the business is also an unusual one: directors Chris and Christine Hewick are Andoverbased farmers. The relationship between the group of people stems from the Hewick’s Cave Liquid Haulage business, a company set up by the couple to buy, sell and manage co-product. Along with supplying co-product commodities for large scale manufacture of animal feed, Cave Liquid Haulage also offers a full service for farmers – with the installation of on-site bulk tanks and ancillary equipment.

How it all started

“Hewicks Haulage was originally started as a costeffective, manageable means of collecting and delivering the products Cave Liquid Haulage bought and sold. It was a simple case of buying trucks to service the work the business already had, not the opposite way round,” Brinkley recalls. This all dates back to 2002 when Brinkley was one of the two founding drivers. Now his remit is looking after the office side of the operation, managing 18 tractors, 12 bulk liquid tankers and one semi-low-loader. Despite miles of separation and the fact both companies are run as two separate entities, one sentence from Brinkley confirms Chris and Christine undoubtedly favour the hands-on approach.

The working partnership performs well, with Chris and Christine understanding more about the nature of transport, and because their biggest client also owns the company, Brinkley and his team have been able to build a product knowledge base far exceeding that of a normal haulier. As co-product is heavily reliant upon farm-generated commodities, it’s largely seasonal. Dairy and brewing products may be available all year round, but sugar beat co-product is largely dependent on harvesting times. To manage the peaks and troughs, Hewicks can fall back on its semi-low-loader trailer, plus traction-only port work from Felixstowe. Brinkley says that during quiet periods as many as eight could be pulling tilt trailers, but never fewer than two.

When it comes to buying, Hewicks prefers a termbased finance package based on full ownership at the end of the period, rather than any lease or contract hire option. At the load-carrying end, there’s a mix of makes, some better than others. A road tank is nothing more complicated than a giant cylindrical object capable of holding liquid, pellets or powder, but how the cylinder is constructed dictates much of its functionality and longevity. “Take a look at this weld,” Brinkley enthuses, pointing towards a perfect join in one of the firm’s new recently purchased Magyar tankers.

Leasing a truck undoubtedly has its benefits: it’s an asset that quickly becomes someone else’s problem after three or four years. Looking beyond that point brings us neatly round to Scanias, or moreover V8 Scanias. The business was founded with a pair of 4-series V8s, one of which, a mint condition 164-480 Topline of 2003 vintage, is still on the fleet. In today’s environment, what is fast approaching a 10-year lifespan is not to be sniffed at.

After some discussion, the second raft of trucks Hewicks ordered were larger 164-580s: “Chris initially thought the 580 might be too big for our operation,” Brinkley recalls, but as the firm’s owner also holds a C+E licence, a test drive in the beefier 16-litre lump changed his opinion. “In the end we placed an order for three, all in Classic trim.” In service they’ve been almost 100% reliable, with all four needing replacement oil coolers, and two new turbos. “Other than that, there’s been absolutely nothing to report,” he concedes.

Planned maintenance (which includes a self-imposed oil change every 12 weeks) is done back at base by self-employed father and son team Terry and Jamie Barnes, who trade as TJB Repairs and take care of everything outside of the normal two-year R&M period.

Not all plain sailing

Long spells of reliability sadly haven’t extended to smaller engined versions. Four R480s with the 11.7-litre HPI injected Euro-5 powerplant have required more looking after – well past what you might consider to be a touch of newness. One required attention on a rather unbelievable 28 occasions in a 12-month period.

In the search for an alternative, Hewicks decided to look elsewhere – adding three Volvo FH500 Globetrotter XLs to the fleet earlier in the year. All came in ‘Hewicks spec’, with a 6x2 tag chassis configuration. “As a general rule, we’ve shied away from automated gearboxes in the past. When it comes to fuel consumption and slow speed control, we’ve always held the belief that three pedals are better than two.” But Brinkley and Chris do operate a solitary Mercedes Actros 2446, and despite the fact they’ve never specced Scania’s Opticruise, there will always be the temptation to think you might be missing something. “So we ordered one manual and the other two with I-shift.” So far, the trial has confirmed Brinkley’s suspicion – in many ways. In summary however, the manual Volvo is better on fuel than the automated pair.

After 10 years of trials and tribulations, Chris and Brinkley still believe the most recent Scania/Magyar combo is about right, or at least “for now” , the latter of the duo quips. The latest two Swedish additions are extremely high spec: both R620 Toplines riding on full air (front and rear) and shod with low profile tyres, bought from Truckeast in nearby Stowmarket. “The very nature of direct-to-farm deliveries means the potential for uneven ground. With air on the front end you’ve got a more stable ride, and the option to lift the truck clear of any danger.” Going back over a few of our topics, Brinkley admits that given the price for trucks changed in 2012, a high mileage, 10-year plus life for tractors should be the norm, not a total surprise. “If you take everything we’ve spoken about today into consideration, you’ll see why we’ve gone back to Scania and particularly the R620. Barring accidents or things we can’t foresee, both of those trucks should still be with us in 2022. This isn’t an owner-driver’s flight of fancy, it’s the simple fact a 620hp V8 has the potential to last longer,” he reckons.

A closely knit company

It’s a tightly knit team down here, with staff turnover extremely low. Given the industry fuel consumption perception that 11 or 13 litres equals good and 16 litres equals bad (a theory Brinkley might say is the wrong way round), does the operation of flagship V8 Scanias help with driver retention?

“Of course it does,” he replies with a wry smile. “But we’re helped along the way with good training too,” he adds. Trevor Buckle (who is ex-Scania) occupies an office directly above Brinkley’s. His brief is to keep the firm on top of driver training and compliance.

Staying on the subject of drivers, Brinkley closes with some thought-provoking words about the industry and its survival: these days, overzealous health and safety dictates children and trucks don’t mix.

“The result is an entire generation lost,” Brinkley sighs. “In 10 or 20 years’ time we’re going to be in real trouble.

With no new blood coming through, where will the next owners and drivers come from?” he concludes.

It’s a fair point to end on. n