VERNIGHT LOADIM

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

.Cement Deliver

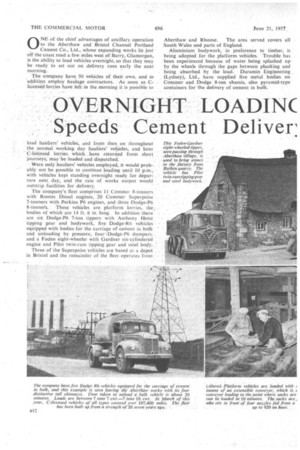

ONE of the chief advantages of ancillary operation to the Aberthaw and Bristol Channel Portland

, Cement Co., Ltd., whose expanding works lie just off the coast road a few miles west of Barry, Glamorgan, is the ability to load vehicles overnight, so that they may be ready to set out on delivery runs early the next morning. '

The company have 50 vehicles of their own, and in addition employ haulage contractors. As soon as.0licensed-lorries have left in the morning it is possible to load hauliers' vehicles, and from then on throughout the normal working day hauliers' vehicles, and later C-licensed lorries which have returned from short journeys, may be loaded and dispatched.

• Were only hauliers' vehicles employed, it would prob.. ably not be possible to Continue loading until 10 p.m., with vehicles kept standing overnight ready for departure next. day, and the rate of works output would outstrip facilities for delivery.

The company's fleet comprises 11 Commer 8-tanners with Rootes Diesel engines, 20 Con-imer Superpaise 7-tonners with Perkins P6 engines, and three Dodge-P6 8-tonnes. These vehicles are platform lorries, the bodies of which are 14 ft. 6 in. long. In addition there are six Dodge-P6 7-ton tippers with Anthony Hoist tipping gear and bodywork, five Dodge-R6 vehicles equipped with bodies for the carriage of cement in bulk and unloading by pressure, four Dodge-P6 dumpers, and a Foden eight-wheeler with Gardner six-cylindered engine and Pilot twin-ram tipping gear and steel body.

Three of the Superpoise vehicles are based at a depot in Bristol and the remainder of the fleet operates from Aberthaw and Rhoose. The area served covers all South Wales and parts of England.

Aluminium bodywork, in preference to timber, is being adopted for the platform vehicles. Trouble has been experienced because of water being splashed up by the wheels through the gaps between planking and being absorbed by the load. Duramin Engineering (Lydney), Ltd., have supplied five metal bodies on Commer and Dodge 8-ton chassis, also pyramid-type containers for the delivery of cement in bulk.

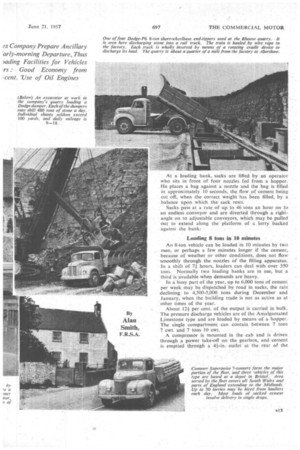

At a loading bank, sacks are fitled by an operator who sits in front of four nozzles fed from a hopper. He places a bag against a nozzle and the bag is filled in approximately 10 seconds, the flow of cement being cut off, when the correct weight has been filled, by a balance upon which the sack rests.

Sacks pass at a rate of up to 46 tons an hour on to an endless conveyor and are diverted through a rightangle on to adjustable conveyors, which may be pulled out to extend along the platform of a lorry backed against the barik., Loading 8 tons in 10 minutes •

An 8-ton vehicle can be loaded in 10 minutes by two , men, or perhaps a few minutes longer if the cement, because of weather or other conditions, does not flow smoothly through the nozzles of the filling apparatus.

In a shift of 74 hours, loaders can deal with over 350 tons. Normally two loading banks are in use, but a third is available when demands are heavy.

In a busy part of the year, up to 6,000 tons of cement per week may be dispatched by road in sacks, the rate declining to 4,500-5,000 tons during December and January, when the building trade is not as active as at other times of the year.

About 124 per cent. of the output is carried in bulk. The pressure discharge vehicles are of the Amalgamated Limestone type and are loaded by means of a hopper. The single compartment can contain between 7 tons 7 cwt. and 7 tons 10 cwt.

A compressor is mounted in the cab and is driven through a power take-off on the gearbox, and cement is emptied through a 44--in. outlet at the rear of the

body. Deliveries are J,nainly made to building sites

where silos are erected.

Bulk-delivery vehicles have been in use by the company for a year. Three more are on order, but their pyramid-type bodies will discharge not by pressure but by tipping, as is simply required for unloading into underground stores found at factories 'where concrete products are made.

Time taken to unload a bulk vehicle by pressure is about 20 minutes, compared with half an hour for a 7-tonner or an 8-tonner with four men handling sacks. Some deliveries to underground stores are being made by the six Dodge 7-ton tippers with pyramid-type bodies. These vehicles used to be employed on the haulage of stones from Ruthen quarry, a function now filled by the Foden, and are to be disposed of after some years of service.

The dumpers, which are 8-tonners and have Telehoist bodywork and Edbro tipping gear, are used internally, hauling stone from the quarry face. They are loaded by mechanical diggers and unload into trucks which are hauled along rails a quarter of a mile to the factory by wire rope.

Dumpers run only 9-18 miles a day, as their individual shunts seldom exceed 100 yd. Each vehicle may shift 480 tons in a day.• In March of this year C-licensed vehicles covered over 107,400 miles. Seven years ago the company had only 20 vehicles of their own,

but have built up an ancillary fleet in step with growing production. Currently, up to 50 lorries may be hired from private hauliers each day for the delivery Of long2 distance as well as local consignments. Most loads of , sacked cement involve delivery in single drops. _ When delivering, vehicles often have to cover rough ground, and this condition underlies the strict attention given to maintenance. Every afternoon there are three vehicles in the company's workshops being lubricated and inspected. Engines are checked and tuned, and the brakes and steering alignment tested.

Illuminated Pits There are two illuminated pits in the workshop, equipment in which includes a Juniper greaser (considered to be as practical and useful as pressure equipment), a Hartridge nozzle lapper, and a Laycock washing plant. Five filters are employed and a night shift is worked so that vehicles need be off the road for servicing for as short a time as possible.

Among the range of spares kept are a P6 engine, injection pumps, starter motors, dynamos, and wheel and master brake cylinders, but stocks need not be extensive because of the company's proximity to vehicle and engine manufacturers' agents in Cardiff and Barry.

Mr. E. V. Marsh, garage supervisor, quoted the follow_ing mileages pertaining to Perkins engines which had been in use since 1950 onwards: 260,768, 127,000, 122,000, 119,000, 117,000 and 115,000. New pistons and rings had been fitted to these units at 95,000 miles, and the engines were expected to give reliable service until the time came for the chassis to be replaced.

Lubricants specified are Shell Rotella S.A.E. 20 for Rootes Diesel and Perkins R6 'engines, and Royal Snowdrift S.A.E. 20 for Perkins P6 engines. Crankcase oils are changed at 3,000 miles and filters at 6,000 miles.

Life of tyres, which are supplied by the Briggs organization, is also remarkably good, 45,000 miles being reckoned as an average for a cover, which may be remoulded after 20,000 miles. Mr. Marsh attributed this success to the checking of pressures every morning before vehicles set out on their journeys, and to the trouble taken in pairing twin rear wheels so that one cover would not be matched with another that was much more, or less, worn.

Little trouble has been experienced with stones lodging between twin rear wheels except with the internal dumpers. Remoulded tyres are not fitted to front axles. Some covers have• lasted over 60,000 miles. Average 'cost per mile for tyres is 0.8d.

Apart from the road activities, a certain amount of cement is carried by rail, notably to the Bristol depot and to an asbestos company from the nearby Rhoose works. Great savings in the cost of hiring outside haulage have been made since the C-licence fleet has been built up, and the profitability of the company's vehicles is checked by a thorough costing system which also shows when it is economic to renew vehicles.

Each vehicle has a costing sheet, across the top of which run" the f011owing headings: earnings, mileage, •gallons Of fuel,. , tonnage, dayslost, and wages, split under sub-headings for drivers and repair staff.

There are further columns for: cost of fuel, lubricants, tax, insurance, interest, depreciation, repairs and renewals, tyres, and subsistence and garage expenses. Interest on capital outlay is, reckoned at 5 per cent. and depreciation at 20 per cent. a year.

All outgoings are totalled each month and compared _ with the income represented by delivery charges, which are on a par with reasonable haulage rates. In the final columns either a debit or a profit for a month's working may be entered.

Every six months the statistics for groups of vehicles, classified according to type, are summarized for purposes of comparison. • Drivers are awarded a conduct bonus at the end of the year. If free from accident, whether blameworthy or not, men gain a 10s. bonus every six months.