How THE ROAD TANKE

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

HAS ACHIEVED SUCCESS

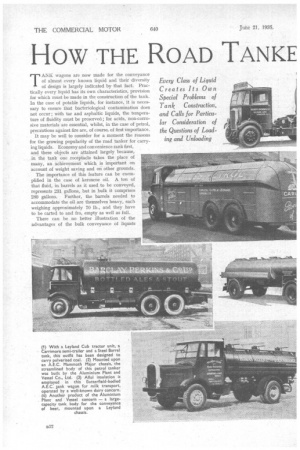

TANK wagons are now made for the conveyance of almost every known liquid and -their diversity . of design is largely indicated by that fact. Practically every liquid has its own characteristics, provision for which must be made in the construction of the tank. In the case of potable liquids, for instance, it is necessary to ensure that bacteriological contamination does not occur ; with tar and asphaltic liquids, the temperature of fluidity must be preserved ; for acids, non-corrosive materials are essential, whilst, in the case of petrol, precautions against fire are, of course, of first importance.

It may be well to consider for a moment the reasons for the •growing popularity of the road tanker for carrying liquids. Economy and convenience rank first, and these objects are attained largely because, in the tank one receptacle takes the place of many, an achievement which is important on account of weight saving and on other grounds.

The importance of this feature can be exemplified in the case of kerosene oil. A ton of that fluid, in barrels as it used to be conveyed, represents 231 gallons, but in bulk it comprises 280 gallons. Further, the barrels needed to accommodate the oil are themselves heavy, each weighing approximately 70 lb., and they have to be carted to and fro, empty as well as full.

There can be no better illustration of the advantages of the bulk conveyance of liquids than in the case of petrol. fn • pre-tanker days, petrol was carried in two-gallon cans—a most expensive method of handling. The present-day 2,400gallon tank replaces, of course, 1,200 of these cans. The tank is filled once and emptied once, these two operations comparing with 2,400 in the case of the cans.

In considering the various fluids, and the features of the tanks which are used for their conveyance, petrol. comes first to mind, as involving more peculiarities in the chassis and tank than does any other liquid. Petrol tankers are made in capacities as great as 2,500 gallons for use in this country up to 4,000 gallons and even larger for operation abroad. In the case of road tankers for use in this country, for quantities in excess of 1,500 gallons, the sanction of the Home Office has to be obtained, both as to the construction of the tank and its materials, and as to the design of the chassis, with particular reference, amongst other things, to axle weights.

These petrol tanks are divided into compartments and none must contain more than 600 gallons. Moreover, baffle plates must be fitted in each compartment to minimize surging of the liquid. A manhole or man-way is fitted to each section and the cover embodies the filling apparatus. The filling pipe has to be designed to afford a liquid seal and any opening in it is usually covered by Davy gauze.

A pressure-relief valve is sometimes fitted to each compartment and is adjusted to blow off • at 2-3. lh,. per sq.:in. This is a! safeguard against the pressure in the tank building up during hot weather. Each COMpartment has a foot valve embodied in the pipes for emptying, so that in the event of the vehicle accidentally moving while the petrol is being discharged, this valve automatically closes. It also operates. in the event of an accident which dainages. or otherwise opens the dis-, charge cocks. The cocks by which the tank is emptied must be padlocked when not in use and be protected from the possibility of damage in collision.

A special precaution is that 'which has to he taken against the risk of explosion from the generation of static electricity while petrol is being poured into the tank. To obviate this ,possibility, the metal of the tank is earthed during the filling operation.

Generally, the filling orifice is designed so that it cannot be opened until this earthing has been effected. Before the cover can be opened, a brass plug must be inserted in the fitting, the plug being properly earthed.

There are further precautions taken in respect of the chassis of the tanker. The most important of these is the 4, provision of a fire-proof screen between the engine and all its essential components, including, of course, the fuel tank and the main tank. This screen must extend upwards to at least the topmost portion of the tank and downwards to within 12 ins, of the ground, and there must be a clear space of 6 ins. between it and the tank.

All essential components of the electrical equipment must' be in front of the screen. The wiring on the chassis must

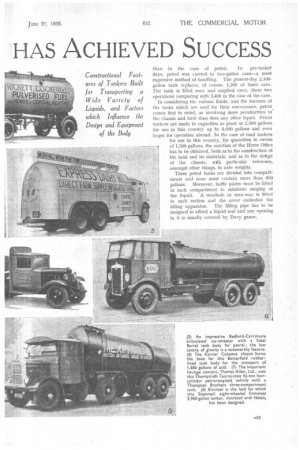

be of the armoured type, the circuit must be double pole and must embody a special double-pole switch or similar device fitted close to the battery. If the vehicle be left standing in a garage, the switch must be " off." Milk is another liquid of which vast quantities are carried by road in tankers. Tanks for the conveyance, of milk may be glass-lined, steel-coated with special materials, of stainless steel, of pure aluminium or aluminium alloy. The interior of the tank, if of metal, must be perfectly smooth and have widely radiused corners. All welds are hammered or ground smooth according to the metal employed.

Milk tanks are insulated and one of the most popular materials for that purpose is Alfol, which is extremely thin aluminium foil packed lightly between the outer surface of the main tank and an outer covering of light mild steel or aluminium sheets. Milk is usually delivered to the.ta,nk at a temperature of about 40 degrees F. and should not rise more than a few degrees in transit, sometimes over a distance of 200 miles.

Other potable liquids, such as beer, fruit juices, syrup and nut oils, are carried in tanks similar in general description to those for milk, but there is not always the need for such effective insulation.

In the case of tar and asphaltic liquids, provision is sometimes 'made for maintaining the temperature or even raising it prior to discharge, heater tubes being fitted into the tank. Generally speaking, however, careful insulation, after the manner described in connection with milk tanks, is sufficient.

Sonic curious and seemingly contradictory conditions prevail in connection with the conveyance of certain acids. B34 Strong sulphuric acid, for example, can be carried in plain mild-steel tanks, the only concession" being to use metal of a little heavier/gauge, in order to provide against the extra corrosion that may occur.

Pure sulphuric acid cannot be carried in this way, and for its conveyance only glass-lined tanks are permitted. Glass-lined tanks are used also for ammonia, but for hydrochloric acid the tanks must be lined with rubber or ebonite, whilst ebonite cocks are usually fitted to control the outWard flow. Incidentally, in the case of all tankers carrying acids or similar dangerous liquids, the same provision as regards the padlocking and guarding of the cocks has to be made as in connection with petrol tankers. , The most recent development in tank construction is the use of containers of this kind for pulverized coal, as supplied for power and central heating.

In many cases, the liquid, such as acid, tar or glucose, is too viscous to be discharged under the influence of gravity alone. In such instances, the vehicle carries an air compressor which delivers air into the tank at the top, forcing out the liquid. The compressor is usually driven by gearing from the mechanism of the chassis. In some instances, however, an independent compressor is mounted, provided with its own small petrol engine. The latter type is, perhaps, the more economical for use on extremely large tankers carrying slow-moving liquids, because in the alternative method the operation of the much bigger vehicle engine, during the whole of the discharge period, is involved.

In selecting the compressor, regard must be had to the eeed for haste when unloading. Capacities vary from 10 cubic, ft. of free air per minute to 60 cubic ft., and the pressure is from 30 lb. to 65 lb. per sq. in,. As an example of compressor size in relation to speed of emptying, a typical example is the three-cylindered unit incorporated in Scammell chassis. This appliance has a capacity of 60 cubic ft. of free air per minute, operating at a pressure of up to 70 lb. per sq. in. With it, -a 3,000-gallon tank can be discharged in.15 minutes through a 3-in. hose pipe.

Another consideration to be borne in mind, when determining the dimensions of a compressor and the pressure at which it works, is the possibility of the need for lifting the fluid from the tank to a height above ground level.

In the majority of cases, the tanks are mounted on bearers and some form of shock insulation is embodied in the mounting. Some manufacturers of tanks use Silentbloc bearings between the tank and the bearers, whilst others employ rubber. In certain articulated vehicles the tank itself is made to do duty as the chassis of the load-carrying portion of the complete unit.

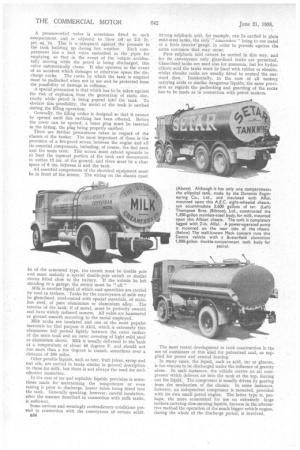

Aluminium is largely replacing steel as a constructional material. This procedure is comparatively recent, becoming possible only when methods of welding aluminium into of this size were perfected.

The most recent development is not so much a matter of utility as of appearance. Plain aluminium tanks are attractive in their natural finish, and they can be used to advantage for advertising purposes if polished, varnished and lettered, In the case of other uninsulated tanks, external panelling of aluminium or metal-faced plywood is sometimes fitted. The panels are supported on brackets attached to the chassis and an attractive streamline effect is attained.