IMPRESSIONS AVVD MULTIDRIVE

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

appears to be minimal. This has allowed Bennie to achieve around 70,000km from some of them: the last pair of orginal XZAs was only recently replaced.

Drive-axle tyres on the Volvo eightleggers are achieving only 30-32,0001= on average, and at £415 apiece for Michelin 12R22.5 XZAs, this represents a considerable saving despite it having four more fitted. With the extra four tonnes carried on each trip, the tyre cost per tonne is also obviously much better than that of the 8x4s.

Bennie is currently deploying the Multidrive on general delivery work, carrying in-fill and road building materials between its quarry east of Banbury to feeder routes under construction for the M40 extension. It also makes longer journeys with a return-load arrangement.

Under these working conditions, Rhead says that the 227kW (304hp) 14-litre Cummins NTE 320-powered Scammell 20.32 is giving a fuel return in the lower 40 litres/100km (upper sixes, in mpg terms) compared with around 37.5 litres/ 100km (7.5mpg) from the Volvo eightwheelers.

In terms of initial outlay, a Volvo FL10320 6x2 with an air-suspended pusher axle, coupled to a 200 steel or alloy body and with Edbro DS18 tipping gear, retails at around £68,000 — some 210,000 more than a typical conventional 8x4 rigid-bodied tipper.

Like the Scammell S26 version, the FL10 6x2 Multidrive combination is equipped with cross and inter-axle differential locks but with Tadchurch rubber suspension on the trailer bogie. Only the extra set of diff-lock control buttons for the rear bogie indicates that there is anything out of the ordinary inside the cab.

• HANDLING

To gain handling impressions we tried the Scamrnell S26 10x6 Multidrive, laden with 23.5 tonnes of infill soil to within 300kg of its 38.0 tonnes GCW limit, in company with its regular driver, Mick Roberts.

It was only about 18 kilometres along the A422 from the quarry to the roadworks near Middleton Cheney, but they were narrow winding roads with difficult junctions, especially the northern diversion around Banbury.

The way that the rearmost axles follow the path of the front steered axles is uncanny and takes a while to get used to after years of allowing room for artic trailers to cut in. This gives the entire outfit the same degree of manoeuvrability as the tractive unit itself.

Under power there is a certain amount of understeer, especially when laden, but the driver quickly becomes accustomed to it and makes the necessary allowance.

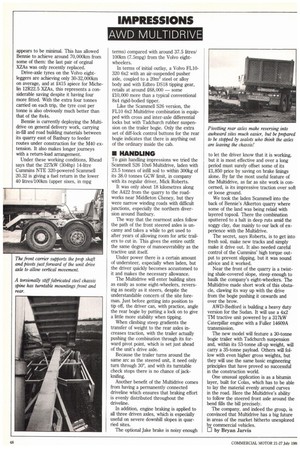

The Multidrive will enter building sites as easily as some eight-wheelers, reversing as neatly as it steers, despite the understandable concern of the site foreman. Just before getting into position to tip off, the driver can, with practice, angle the rear bogie by putting a lock on to give a little more stability when tipping.

When climbing steep gradients the transfer of weight to the rear aides increases traction, with the trailer actually pushing the combination through its forward pivot point, which is set just ahead of the unit's drive axle.

Because the trailer turns around the same arc as the steered unit, it need only turn through 300, and with its turntable check stops there is no chance of jackknifing.

Another benefit of the Multidrive comes from having a permanently connected driveline which ensures that braking effort is evenly distributed throughout the driveline.

In addition, engine braking is applied to all three driven axles, which is especially useful on severe downhill slopes in quarried sites.

The optional Jake brake is noisy enough to let the driver know that it is working, but it is most effective and over a long period must surely offset some of its £1,850 price by saving on brake linings alone. By far the most useful feature of the Multidrive, as far as site work is concerned, is its impressive traction over soft or loose ground.

We took the laden Scanuinell into the back of Bennie's Alkerton quarry where some of the land was being relaid with layered topsoil. There the combination sputtered to a halt in deep ruts amid the soggy clay, due mainly to our lack of experience with the Multidrive.

The secret, says Roberts, is to get into fresh soil, make new tracks and simply make it drive out. It also needed careful control of the Cummins' high torque output to prevent slipping, but it was sound advice and it worked.

Near the front of the quarry is a twisting shale-covered slope, steep enough to baulk the company's eight-wheelers. The Multidrive made short work of this obstacle, clawing its way up with the drive from the bogie pushing it onwards and over the brow.

AWD-Bedford is building a heavy duty version for the Sudan. It will use a 4x2 TM tractive unit powered by a 317kW Caterpillar engine with a Fuller 14609A transmission.

The new model will feature a 30-tonne bogie trailer with Tadchurch suspension and, within its 53-tonne all-up weight, will carry a 35-tonne payload. Others will follow with even higher gross weights, but they will use the same basic engineering principles that have proved so successful in the construction world.

One unusual application is as a bitumin layer, built for Colas, which has to be able to lay the material evenly around curves in the road. Here the Multidrive's ability to follow the steered front axle around the bend fills the bill precisely.

The company, and indeed the group, is convinced that Multidrive has a big future in areas of the market hitherto unexplored 12y commercial vehicles.

LJ by Bryan Jarvis