TOUGH ON

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

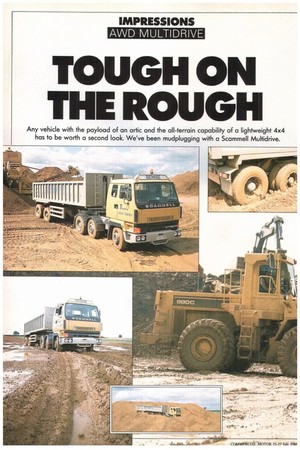

THE ROUGH • Onlookers gaped in astonishement as, with all its wheels driving, the AWDBedford TM8x8 Multidrive clawed its way up and over a 30° knife-edged test slope.

It ground its way over relentlessly, forcing the front of the truck to dangle in mid-air on its travel stops before being lowered gently as the combinations' three still-gripping axles drove on.

The stunt was staged at last month's British Army Equipment Exhibition (BAEE'88), where Bedford Truck's successor was demonstrating an intriguing addition to its range of military vehicles. With its 25-tonne payload capacity, the 8x8's astonishing climbing capability made it abundantly dear, that here was a logistical support vehicle with a difference.

Its quintessential element is the Multidrive system, which propels and steers the rear axles of the trailer, and interest in the on/off road package (which meets all Construction and Use requirements) is not confined to the military — forestry, mining and construction companies as well as a number of important overseas markets have shown great interest.

Tipper operator Bennie of Northampton has been operating a Leyland Daf Scammell S26 Multidrive 10x6 combination for almost a year — and it has ordered another four. Bennie runs the Multidrive alongside an 80-strong fleet of Volvo rigid 8x4 tippers, but due to the earlier uncertainty of the Leyland Daf Scamrnell situation, Bennie has insisted on FL10s as the base units for its new quartet, the first of which will be delivered next month. We were intrigued to see how the S26 Multidrive was faring in a cost-sensitive civilian environment, and to find out how it handled on normal roads.

EARLY PROTOTYPE

Multidrive's situation has changed somewhat since our brief drive of an early prototype two years ago, when the company was an offshoot of the DJI/Artix group of specialist vehicle manufacturers. Now that David Brown has bought the Bedford Truck and Bus business from General Motors, Multidrive is part of a family that employs nearly 2,000 people in its former base of Peterlee, County Durham and at the 39ha Dunstable plant.

Few detail changes have been made to the earlier Multidrive design, which applies David J B Brown's successful dumper driveline system to an articulting trailer with a live bogie, permanently driven by a set of three propellor shafts from the tractive unit. The centre shaft has extra long splines in its flexible joint to absorb the extra deflection of full-lock steering. Trailers are built to the same fabricated spine-back design and have a sealed drawbar-type turntable (similar to one on the rear bogie) in place of a conventional fifth wheel.

They are connected by flat steel bars (hexagonal ones were used originally) which cross through slots in the trailers centre spine and steer the rear axles through angles which correspond with the turning angles of the tractor's axles.

The unit's turntable is mounted on Multidrive's patented carrier frame. This supports the output propshaft through its 30° pivoting movement which allows for oscillation between the unit and trailer. Its movement is restricted by stops on the turntables which can be moved to suit an operator's needs.

Over the past twelve months Bennie has used the Scammell S26 6x2 Mackworth-bodied combination on a variety of tipping jobs, comparing it against its Volvos, and in a number of areas the Multidrive artic beats them.

According to Bernie's transport manager Bob Rhead, it carries 20% (4.00 tonnes) more payload than the Volvos and certainly lives up to Multidrive's claim of increased trailer tyre life. Thanks to its rear-steer arrangement, tyre scrub