Stressed-skin Construction in Low-priced Coach

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

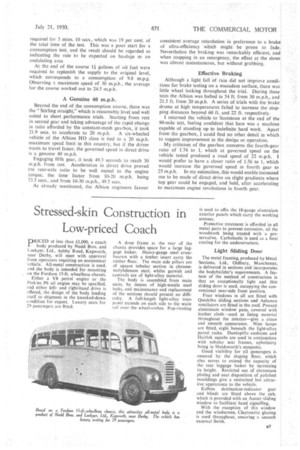

PRICED at less than £1,000, a coach body produced by Nudd Bros. and Lockyer, Ltd., Ashby Road, Kegworth, near Derby, will meet with approval frona operators requiring an economical vehicle. All-metal construction is used, and the body is intended for mounting on the Forclson I5-ft. wheelbase chassis.

Either a V8 petrol engine or the Perkins P6 oil engine may be specified, and either leftand right-hand drive is offered, the design of the body lending itself to shipment in the knocked-down condition for export. Luxury seats for 29 passengers are fitted. A drop frame at the rear of the chassis provides space for a large Wegage locker. Heavy-gauge steel crossbearers with a timber insert carry the timber floor. The main side pillars are of square tubular section in chromemolybdenum steel, whilst garnish and cantrails are of light-alloy material.

The body is assembled from main units, by means of high-tensile steel bolts, and maintenance and replacement of the sections should present no difficulty. A full-length light-alloy truss panel extends on each side to the waist rail over the wheel-arches. Pop-riveting is used to affix the 18-gauge aluminium exterior panels which carry the working stresses.

Protective treatment is afforded to all metal parts to prevent corrosion, all the woodwork being treated with a preservative. Carbolastic is used as a final coating for the understructure.

Light Sliding Door The metal framing, produced by Metal Sections, Ltd., Oldbury, Manchester, is delivered in sections and incorporates the bodybuilder's requirements. A feature of the method of construction is that an exceptionally light and thin sliding door is used, occupying the conventional near-side front position.

Four windows in all are fitted with Quicktho sliding sections and Ashanco ventilators are fitted in the roof. Pressed aluminium window pans, covered with leather cloth—used as lining material throughout the interior—give a clean and smooth appearance. Nine lamps are fitted, eight beneath the light-alloy parcel racks. Dunlopillo cushions and Hairlok squabs are used in conjunction with tubular seat frames, upholstery being in Holdsworth's moquette.

Good visibility for all passengers is ensured by the sloping .floor, which also serves to extend the capacity of the rear luggage locker by increasing its height. Retricted use of chromium plating and neat disposition of polished mouldings give a restrained but attractive appearance to the vehicle.

Kelbus destination-indicator gear and blinds are fitted above the cab. which is provided with an Auster sliding window to facilitate hand signalling.

With the exception of this window and the windscreen, Claytonrite glazing is used throughout, ensuring a smooth external finish.