ANOTHER A( IESS ALBION

Page 38

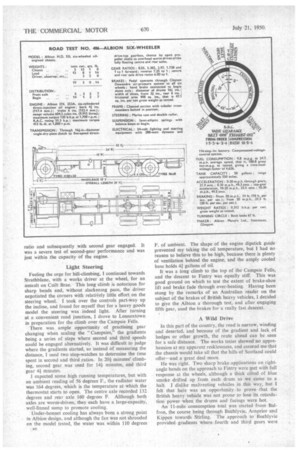

Page 39

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

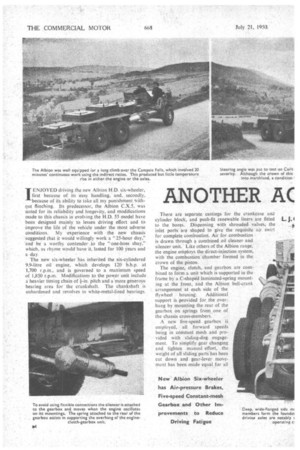

IENJOYED driving the new Albion H.D. six-wheeler, first because of its easy handling, and, secondly, because of its ability to take all my punishment without flinching. Its predecessor, the Albion C.X.5, was noted for its reliability and longevity, and modifications made to this chassis in evolving the H.D. 55 model have been designed mainly to lessen driving effort and to improve the life of the vehicle under the most adverse conditions. My experience with the new chassis' suggested that it would willingly work a ".25-hour day," and be a worthy contender to the "one-boss shay," which, as rhyme would have it, lasted for 100 years and a day.

The new six-wheeler has inherited the six-cylindered 9.9-litre oil engine, which develops 120 b.h.p. at 1,700 r.p.m., and is governed to a maximum speed of 1,850 r.p.m. Modifications to the power unit include a heavier timing chain of 4--in. pitch and amore generous bearing area for the crankshaft. The chankshaft is unhardened and revolves in white-metal-lined bearings. There are separate castings for the crankcase and cylinder block, and push-fit renewable liners are fitted to the bores. Dispensing with shrouded valves, the inlet ports are shaped to give the requisite air swirl for complete combustion. Air for combustion is drawn through a combined oil cleaner and silencer unit. Like others of the Albion range, the engine employs the direct-injection system, with the combustion chamber formed in the crown of the piston.

The engine, clutch, and gearbox are combined to form a unit which is supported in the frame by a C-shaped laminated-spring mounting at the front, and the Albion bell-crank arrangement at each side of the flywheel housing: Additional support is provided for the overhang by mounting the rear of the gearbox on springs from one of the chassis cross-members.

A new five-speed gearbox is employed, all forward speeds being in constant mesh and provided with sliding-dog engagement. To simplify gear changing and lighten manual effort, the weight of all sliding parts has been cut down and gear-lever movement has been made equal for all changes of ratios. The new gearbox case is a singlepiece aluminium casting which is adequately ribbed for rigidity and soundproofing.

Hardy Spicer universal joints are provided in a twopiece propeller shaft, which has a torsion damper to reduce vibration. Both driving axles and their moving parts have the appearr ance of being able to resist the worst treatment that could be given them overseas. Formed from a single forging, each axle is mounted On a pair of semi-elliptic springs anchored at one end to the frame and coupled at their adjacent ends to a rocking beam carried on a large-diameter trunnion btaring. The axle shafts are l ins. in diameter and are machined from 100-ton steel.

A change has been made in the braking system, and the H.D. model has Clayton Dewandre compressed-air equipment operating the shoes at all six wheels. The air-pressure operating cylinders. one for each wheel, are connected zo levers, which in turn actuate the cams. The Albion designers are conservative in their policy of vehicle braking, and hold the opinion that cam operation is a

most reliable system for combating fade when descending long declines.

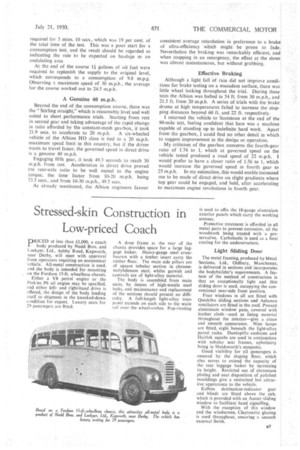

Because of the compressed-air equipment, the pedal effort required for normal retardation is relatively light, and additional physical effort increases braking efficiency proportionally. The air equipment includes a twocylindered engine-driven compressor, supplied with air from the engine induction system, and a large reservoir with an unloader to rest the compressor when the system is at working pressure. The hand brake is of multi-pull ratchet type, with trigger release, and is connected to the shoes of the centre and rear axles.

I collected the Albion, together with its 13i-ton load, from Scotstoun, and straightaway put it to test on the 1-in-6 gradient of Clevedon Road. Glasgow abounds with short, sharp gradients such as this, which often reduce some of the best vehicles to a bottom-gear crawl. During a straight climb, the Albion made the grade in second gear. with a reserve of engine power. After returning to the steepest section, a stop-start trial was successfully accomplished, first by employing the lowest

ratio and subsequently with second gear engaged. It was a severe test of second-gear performance and was just within the capacity of the engine.

Light Steering

Feeling the urge for hill-climbing, I continued towards Strathblane, with a works driver at the wheel, for an assault on Cuilt Brae. This long climb is notorious for sharp bends and, without slackening pace, the driver negotiated the corners with relati■rely little effort on the steering wheel. I took over the controls part-way up the incline, and found for myself that for a heavy goods model the steering was indeed light. After turning at a convenient road junction, 1 drove to Lennoxtown in preparation for the climb over the Campsie Fells.

There was ample opportunity of practising gear changing when scaling the " Campsies," the gradients being a series of steps where second and third speeds could be engaged alternatively. It was difficult to judge where the gradients started, so instead of measuring the distance, I used two stop-watches to determine the time spent in second and third ratios. In 20i minutes' climbing, second gear was used for 14i minutes, and third gear 4i Minutes.

I expected some high running temperatures, but with an ambient reading of 56 degrees F., the radiator water was 164 degrees, which is the temperature at which the thermostat starts to open. The centre axle recorded 132 degrees and rear axle 160 degrees F. Although both axles are worm-driven, they each have a large-capacity, well-finned sump to promote cooling.

Under-bonnet cooling has always been a strong point in Albion design, and although the fan was not shrouded on the model tested, the water was within 110 degrees 136 F. of ambient. The shape of the engine dipstick guide prevented my taking the oil temperature, but I had no reason to believe this to be high, because there is plenty of ventilation behind the engine, and the amply cooled base holds 41 gallons of oil.

It was a long climb to the top of the Campsie Fells, and the descent to Fintry was equally stiff. This was good ground on which to test the extent of brake-shoe lift and brake fade through over-heating. Having been stung by the remarks of an Australian reader on the subject of the brakes of British heavy vehicles, I decided to give the Albion a thorough test, and after engaging fifth gear, used the brakes for a really fast descent.

A Wild Drive

In this part of the country, the road is narrow, winding and deserted, and because of the gradient and lack of hedges or other growth, the route ahead can be seen for a safe distance. The works tester showed no apprehension at my apparent recklessness, and assured me that the chassis would take all that the hills of Scotland could offer—and a great deal more.

He was right. Two sharp brake applications on rightangle bends on the approach to Fintry were met with full response at the wheels, although a thick clOud of blue smoke drifted up from each drum as we came to a halt. I dislike maltreating vehicles in this way, but I felt that here was an opportunity to prove that the British heavy vehicle was not prone to lose its retardation power when the drums and facings were hot.

An I1-mile consumption trial was started from Balfron, the course being through Buchlyvie, Arnprior and Kippen towards Stirling. The approach to Buchlyvie provided • gradients where fourth and third gears were required for 5 mins. 10 secs., which was 19 per cent, of the total time of the test. This was a poor start for a consumption test, and the result should be regarded as indicating the rate to be expected on haulage in an undulating area.

At the end of the course l gallons. of oil fuel were required to replenish the supply to the original level, which corresponds to a consumption of 9.8 m.p.g. Observing a maximum speed of 30 m.p.h., the average for the course worked out to 24.5 m.p.h.

A Genuine 40 m.p.h.

Beyond the end of the consumption course, there was the "Stirling straight," which is reasonably level and well suited to short performance trials. Starting from rest in second gear and taking advantage of the rapid change in ratio' afforded by the constant-mesh gearbox, it took

21.9 secs. to accelerate to 20 m.p.h. A six-wheeled vehicle of the Albion HD class is tied to a 20 tn.p.h. maximum speed limit in this country, but if the driver wants to travel faster, the governed speed in direct drive is a genuine 40 m.p.h.

Engaging fifth gear, it took 49.3 seconds to reach 30 m.p.h. from rest. Acceleration in direct drive proved toe rear-axle ratio to be well mated to the engine torque, the time factor from 10-20 m.p.h. being 23.5 secs., and from 10-30 m.p.h.. 49.5 secs.

As already mentioned, the Albion engineers favour consistent average retardation in preference to a brake of ultra-efficiency which might be prone to fade. Nevertheless the braking was remarkably efficient, and when stopping in an emergency, the effect at the shoes was almost instantaneous, but without grabbing.

Effective Braking Although a light fall Of rain did not improve conditions for brake testing on a macadam surface, there was little wheel locking throughout the trial. During these tests the Albion was halted in 54 ft. from 30 m.p.h., and 21.5 ft. from 20 m.p.h. A series of trials with the brake drums at high temperatures failed to increase the stopping distances beyond 60 ft. and 22 ft. respectively.

I returned the vehicle to Scotstoun at the end of the 90-mile test, feeling confident that here was a machine capable of standing up to indefinite hard work. Apart from the gearbox, I could find no other detail in which to suggest improvement in the design or operation.

My criticism of the gearbox concerns the fourth-gear ratio of 1.74 to 1, which at governed speed on the vehicle tested produced a road speed of 22 m.p.h. 1 would prefer to have a closer ratio of 1.56 to 1, which would increase the governed speed in fourth gear to 25 m.p.h. In my estimation, this would enable increased use to be made of direct drive on slight gradients where top gear could be engaged, and held, after accelerating to maximum engine revolutions in fourth gear.