GARAGE TOOLS AND APPLIANCES.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

Practical Suggestions by Our Driver and Mechanic Readers.

THE Many uses to which a hand or breast drill can be put in the garage are apparent when reading the suggestions of " G.A.L.," of Washington, D.C., to whom this week's prize of 15s. is awarded.

The drill may be fixed to the bench by means of A bolt which passes through the bench and screws into the hole normally occupied by the fixed handle. Items which may be dealt with :when the drill is thus mounted are :— Cleaning carbon off valves, cleaning Spark phig porcelains and lapping small bearings by fixing the parts in question into the chuck and rotating them ; a small grinding wheel fixed to a spindle may be used, also small parts which require " trimming " can be driven round while a file is held against the surfaces.

In addition to the ordinary work of drilling holes, the drill May he used for carrying a wire scratch brush for carbon removal, a flexible wire cable can be fixed in the chuck and driven

while it is being passed through an oil pipe in order to clear it, a reamer may be driven for enlarging taper-pin holes, small screws may be inserted by means of a screwdriver blade, a scratch brush may be used for roughing inner tubes prior to patching, and so forth.

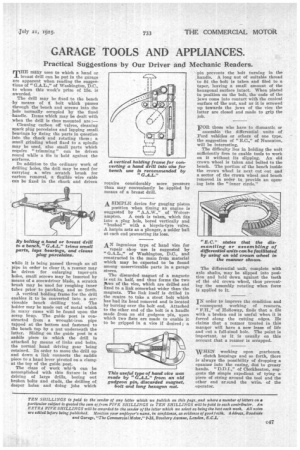

A vertical holding frame for the drill enables it to be converted into a serviceable bench drilling tool. The holder may be made out of metal which in many cases will be found upon the scrap heap. The guide post is constructed from a wrought-iron pipe tapped at the bottom and fastened to the bench top by a nut underneath the latter. Sliding on the guide post is a saddle piece to which the drill is attached by means of links and bolts, the normal hand driving gear being retained. In order to move the drill up and down a link connects the saddle piece to a hand lever pivoted on a clamp at the top of the guide post.

The class of work whi eh can be accomplished with this fixture is the driving of large drills, boring out broken bolts and studs, the drilling of deeper holes and doing jobs which require considerably more pressure than may conveniently be applied by means of a breast drill.

A SIMPLE device for gauging piston

position when timing an engine is suggested by " A.A.W.," of Wolverampton. A cork is taken, which fits into a plug hole, bored vertically and " hushed " with a bicycle-tyre valve. A hatpin acts as a plunger, a solder ball at each end preventing its loss.

AN ingenious type of hand vice for repair shop use is suggested by " G.A..L.," of Washington, D.C., and constructed in the main from material which may be expected to be found among unserviceable parts in a garage stores.

The discarded magnet of a magneto is cut in half, and thus forms the two Yaws of the vice, which are drilled and fixed to a link somewhat wider than the magnets. The link itself is drilled in the centre to take a stout bolt which has had its head removed and is located by burring over the bolt end. Attached to the other end of the bolt is a handle made from an old gudgeon pin, upon 'which two fiats are made to enable it to be gripped in a vice if desired ; a pin prevents the bolt turning in the handle. A long nut of suitable thread to fit the bolt is taken and filed to a taper, leaving a small amount of the hexagonal surface intact. When placed in position on the bolt, the ends of the jaws come into contact with the conical surface of the nut, and as it is screwed up towards the jaws of the vice the latter are closed and made to grip the job.

FOIt those who have to dismantle or assemble the differential units of Ford vehicles or others of one type, the suggestion of "E.C.," of Nuneaton, will be interesting.

The difficulty lies in holding the unit sufficiently firm to enable tools to work on it without its slipping. An old crown wheel is taken and bolted to the bench. The portion of the bench inside the crown wheel is next cut out and a sector of the crown wheel and bench removed in order to provide an opening into the "inner circle."

The differential unit, complete with axle shafts, may be slipped into position and held down against the teeth of the old crown wheel, thus preventing the assembly rotating when force is applied to it.

IN order to improve the condition and

consequent working of reamers, "PH.," of Holloway, finds that a file with a broken end is useful when it is forced along the cutting edges. He claims that a reamer treated in this maneer will have a new lease of life and cut a full-sized hole. The point is important, as it is usually on this account that a reamer is scrapped.

WHEN working upon gearboxes,

clutch housings and so forth, there is always the possibility of dropping a spanner into the casing, due to greasy hands. "D.D.I.," of Cleckheaton, suggests the simple expedient of tying a piece of string around the tool and the• other end armed the wrist. of the operator.