UPDATING BRAKES FOR 1973

Page 32

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

The handbrake regulations for 1973 applicable to pre-1968 vehicles are cut and dried but vehicle manufacturers and equipment makers are restlessly awaiting details of implementation. And many operators have been making the wrong assumptions.

by Paul Brockington, MIMechE

WHEN new braking standards were introduced four years ago for "heavy motor cars" (vehicles of at least 3 tons unladen weight) first used on or after January 1 1968, concessions for existing, pre-1968 vehicles were announced. These allowed rigid two-axle vehicles to have braking efficiencies of only 45 per cent and 20 per cent, while multi-axled rigids, artics and vehicle/ trailer combinations were required to have efficiencies of only 40 and 15 per cent for their two principal systems.

These concessions were given on the understanding that such vehicles would eventually have to meet service and secondary brake efficiencies of 50 and 25 per cent — but not before January 1 1973.

A recent CM investigation of conversion problems and prospects relating to these pre-1968 heavy motor cars — in practice mainly lorries and vans — has revealed that some vehicle manufacturers, the majority of operators and a number of brake conversion specialists, have made the wrong assumptions about the 1973 handbrake requirements.

The Department of the Environment's engineering section has recently advised CM that in 1973 the handbrake of a pre-1968 vehicle which is equipped with a main system giving a service-brake efficiency of 50 per cent and a secondary-brake efficiency of 25 per cent will not have to comply with an efficiency requirement, given that it is of the mechanically-applied type. It will simply be required "to effectively prevent a minimum of two wheels from turning when the vehicle is left unattended".

But where a mechanical handbrake on a pre-1968 vehicle is dispensed with, and spring brakes are fitted, they must be capable of holding the vehicle on a 1 in 6.25 gradient (16 per cent) regardless of whether they are used solely for parking or for both parking and secondary brake application.

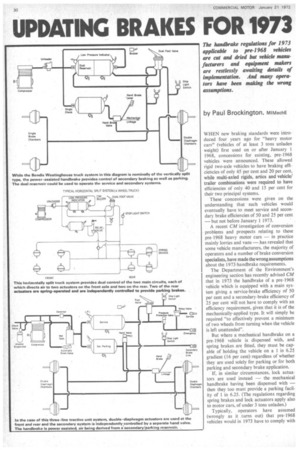

If, in similar circumstances, lock actuators are used instead — the mechanical handbrake having been dispensed with — then they too must provide a parking facility of I in 6.25. (The regulations regarding spring brakes and lock actuators apply also to motor cars, of under 3 tons unladen.) Typically, operators have assumed (wrongly as it turns out) that pre-1968 vehicles would in 1973 have to comply with vehicles, which must be equipped with a handbrake having a parking capacity to meet the 1 in 6.25 rule. The brake may be power assisted, the vehicle being held parked by the force locked in the mechanical linkage. Operators have been known to apply power assistance to the handbrake of a pre-1968 vehicle to obtain this parking performance in addition to service and secondary systems because they have wrongly assumed that it would be necessary in 1973.

When a pre-1968 vehicle is modified so that the mechanical handbrake, probably with power assistance, is used to meet the secondary-brake efficiency of 25 per cent. this handbrake may also be used for parking but without the need to meet the I in 6.25 requirement.

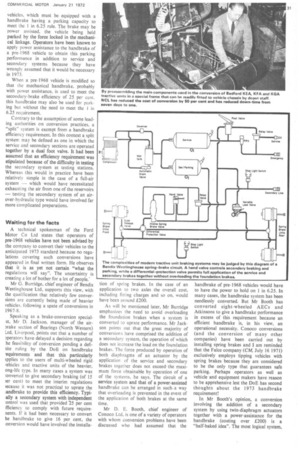

Contrary to the assumption of some leading authorities on conversion practices, a "split" system is exempt from a handbrake efficiency requirement. In this context a split system may be defined as one in which the service and secondary sections are operated together by a dual foot valve. It had been assumed that an efficiency requirement was stipulated because of the difficulty in testing the secondary system at testing stations. Whereas this would in practice have been relatively simple in the case of a full-air system — which would have necessitated exhausting the air from one of the reservoirs — testing the secondary system of an airover-hydraulic type would have involved far more complicated preparations.

Waiting for the facts

A technical spokesman of the Ford Motor Co Ltd states that operators of pre-1968 vehicles have not been advised by the company to convert their vehicles to the anticipated 1973 standard because no regulations covering such conversions have appeared in final written form. He observes that it is as yet not certain "what the regulations will say". The uncertainty is creating a lot of bother for a lot of people.'

Mr G. Burridge, chief engineer of Bendix Westinghouse Ltd, supports this view, with the qualification that relatively few conversions are currently being made of heavier vehicles, following a spate of conversions in 1967-8.

Speaking as a brake-conversion specialst, Mr D. Jackson. manager of the airDrake section of Bearings (North Western) Ltd, Liverpool, points out that a number of verators have delayed a decision regarding he feasibility of conversion pending a deliinc ruling by the DoE on handbrake tquirements and that this particularly 1pplies to the users of multi,wheeled rigid rehicles and tractive units of the heavier, ong-life type. In many cases a system was :onverted to give secondary braking (of 15 ier cent) to meet the interim regulations iecause it was not practical to uprate the Landbrake to provide this efficiency. Typi:ally a secondary system with independent :ontrol was used that provided 5 per cent ,ificiency to comply with future requirenents. If it had been necessary to convert he handbrake to give 16 per cent, the .onversion would have involved the installa

tion of spring brakes. In the case of an application to two axles the overall cost, including fitting charges and so on, would have been around £200.

As will be mentioned later, Mr Burridge emphasizes the need to avoid overloading the foundation brakes when a system is converted to uprate performance. Mr Jackson points out that the great majority of conversions have comprised the addition of a secondary system, the operation of which does not increase the load on the foundation brakes. The force produced by operation of both diaphragms of an actuator by the application of the service and secondary brakes together does not exceed the maximum force obtainable by operation of one of the systems. he says. The circuit of a service system and that of a power-assisted handbrake can be arranged in such.a way that overloading is prevented in the event of the application of both brakes at the same time.

Mr D. E. Booth, chief engineer of Conoco Ltd, is one of a variety of operators with whom conversion problems have been discussed who had assumed that the handbrake of pre-1968 vehicles would have to have the power to hold on 1 in 6.25. In many cases, the handbrake system has been needlessly converted. But Mr Booth has converted eight-wheeled AECs and Atkinsons to give a handbrake performance in excess of this requirement because an efficient handbrake is, in his view, an operational necessity. Conoco conversions (and the conversion of many other companies) have been carried out by installing spring brakes and I am reminded that the Falce company (CM, July 16 1971) exclusively employs tipping vehicles with spring brakes because they are considered to be the only type that guarantees safe parking. Perhaps operators as well as vehicle and equipment makers have reason to be apprehensive lest the DoE has second thoughts about the 1973 handbrake requirement!

In Mr Booth's opinion, a conversion involving the addition of a secondary system by using twin-diaphragm actuators together with a power-assistance for the handbrake (costing over £200) is a "half-baked idea". The most logical system, in his view, is the application of secondary /parking spring brakes to both axles of the bogie, in part because it enables the original handbrake and linkage to be eliminated. In a typical application it gives an efficiency of 27 /28 per cent which is the order of efficiency that is considered desirable. Mr Booth thinks application to one axle is unsatisfactory.

A four-line system has been evolved for Conoco 24-ton three-axle artics, all the wheels of which are braked for parking by spring actuators. Mr Booth points out that the mechanical brake of a semi-trailer is seldom used and the necessity for the driver to leave his cab to apply the brake may be hazardous. Secondary braking is applied to all the axles of threeand four-axle artics and foundation brakes are equipped with SAB slack adjusters which keep the stroke uniform at +in /lin.

Unlikely test case Commenting on the regulation stipulating that the handbrake shall "effectively prevent a minimum of two wheels from turning ...", Mr Burridge observes that a responsible person might reasonably argue in a court of law (in view of current practice) that it implied a gradient holding power of 1 in 6.25 or an efficiency of 16 per cent. The DoE state that such a court case is a "theoretical possibility that is very unlikely to happen".

Comparing spring brakes and lock actuators Mr Burridge told me that Bendix Westinghouse decided to concentrate on the production of spring brakes after producing a number of prototype lock actuators, partly because a lock actuator retracts a short distance before it locks in the parking position. While this is acceptable for cam brakes, lock actuators are less suitable for wedge brakes. The main disadvantage of spring brakes, cited by Mr Burridge, is that inverse control pressure is required, and air may have to be applied under pressure to a semi-trailer system while it is exhausted under pressure from the brakes of the tractive unit. This difficulty has been successfully overcome.

The danger of fatigue failure of foundation brakes arising from the use of higher-capacity actuators in a conversion is the responsibility of the vehicle maker, according to Mr Burridge, and all conversions should therefore be approved by the maker. When power assistance is applied to a handbrake the linkage mechanism may be inadequate to cope with the extra braking force. And with this in mind it is preferable to mount the actuator as close as possible to the wheel brakes to reduce the length of linkage to a minimum.

In the Bendix Westinghouse view the braking-test practices of the DoE testing stations generally favour the operator. For example, the method of checking brakes dynamically on the roller tester with less than the rated load on the axle would normally result in a higher efficiency being recorded than that obtainable on a gradient test. A reading taken when the wheels are revolving in a forward direction of rotation may be "optimistic". Typically, a brake is more efficient when operating in a forward direction and if a handbrake efficiency of 16 per cent or more is recorded, the brake might not hold the vehicle on a 1 in 6.25 gradient when facing up the gradient.

Mr Burridge also emphasizes that the operator may benefit from the service-brake requirement of 0.4g (40 per cent) applicable to a semi-trailer which makes allowance for weight transference when the vehicle is braked on the road and would normally be compatible with an overall efficiency of 0.5g.

NCL's conversions pay off Whether or not it is economic to convert pre-1968 vehicles to the 1973 standard may well depend on the number of vehicles involved and the facilities available to the operator for doing the job in his own workshops. In the case of National Carriers Ltd, such facilities are available and this has enabled a large number of vehicles to be retained in service that would otherwise have been replaced.

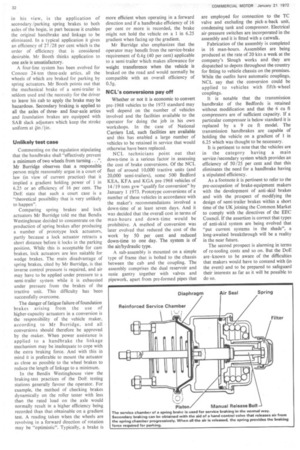

NCL technicians point out that down-time is a serious factor in assessing the cost of brake conversions. Of the NCL fleet of around 10,000 tractive units (and 20,000 semi-trailers), some 500 Bedford KEA, KFA and KGA pre-1968 vehicles of 14/19 tons gvw "qualify for conversion" by January 1 1973. Prototype conversions of a number of these vehicles in accordance with the maker's recommendations involved a down-time of at least seven days. And it was decided that the overall cost in terms of man-hours and down-time would be prohibitive. A method of conversion was later evolved that reduced the cost of the work by 50 per cent and reduced down-time to one day. The system is of the air/hydraulic type.

A sub-assembly is mounted on a simple type of frame that is bolted to the chassis between the cab and the coupling. The assembly comprises the dual reservoir and susie gantry together with valves and pipework, apart from pre-formed pipes that are employed for connection to the TC valve and excluding the pick-a-back unit, condensing tank and compressor. Electrical air-pressure switches are incorporated in the assembly and it is fitted with a catwalk.

Fabrication of the assembly is completed in 16 man-hours. Assemblies are being produced at the rate of 20 kits a week at the company's Slough works and they are dispatched to depots throughout the country for fitting to vehicle chassis on the premises. While the outfits have automatic couplings, NCL say that the conversion could be applied to vehicles with fifth-wheel couplings.

It is notable that the transmission handbrake of the Bedfords is retained without modification and that the 6 cu ft compressors are of sufficient capacity. If a particular compressor is below standard it is replaced by a 9 cu ft model. The transmission handbrakes are capable of holding the vehicle on a gradient of 1 in 6.25 which was thought to be necessary.

It is pertinent to note that the vehicles are in the category having a main serviCe /secondary system which provides an efficiency of 50/25 per cent and that this eliminates the need for a handbrake having a stipulated efficiency.

As a footnote it is pertinent to refer to the pre-occupation of brake-equipment makers with the development of anti-skid brakes and with the prospect of modifying the design of semi-trailer brakes within a short time of the UK joining the Common Market to comply with the directives of the EEC Council. If the assertion is correct that types of anti-skid system are being evolved that "put current systems in the shade", a long-awaited breakthrough will be a reality in the near future.

The second prospect is alarming in terms of re-tooling costs and so on. But the DoE are known to be aware of the difficulties that makers would have to contend with (in the event) and to be prepared to safeguard their interests as far as it will be possible to do so.