Progress an )roduction of a British Oil Engine

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

Pioneer of the Small Oil Engine, F. Perkins, Ltd., having Started 54 Years Ago from Scratch, To-day is a Leader in its Particu

lar Field

STORY. of difficulties overcome, A

obstacles suruiounted, . and a steady advance, from the lowest rung, up the ladder of success to a point where opens a vista of prosperity, is found in the fortunes Of the Perkins oil-engine company, since its birth to the present day. Young in age—it was founded only solong ago as 1932—and staffed almost exclusively by young personnel, the company is vigorous and up to date.

Five years ago, out of some 30 makes of vehicle oil engine, there was no foureylinclered unit of less than 3.7 litres capacity. The founders of F. Perkins, Ltd., saw a market for a smaller engine of low weight, suitable for commercial vehicles in about the 2-ton class, formed the company and commenced the development of the Wolf 2.75-litre unit.

That was in June, 1932, and Mr. F. Perkins, Mr. C. W. Chapman, and Mr. W. F. Failing, who are now, respectively managing director, technical director and works manager, left Aveling and Porter, Ltd., which, -)f course, was associated with Barford and Perkins, Ltd., to go to Peterborough for the ,purpose.

Six months later the first engine was running on test at 3,000 r.p.m. In January, 1.933, 4200 r.p.m. had become practicable. Now Commer Cars, Ltd., comes into the picture, and as a result a Perkins-engined Commer 2-ton chassis was exhibited at the 1933 Commercial Motor Show.

At the beginning of 1934 a demand for Perkins engines really started, and with it an enlargement and reorganization of works and personnel. Where a handful Of skilled men had themselves followed through alt the operations in the building, testing and despatching of the engines—even to the making of

-the packing cases departments . were formed and a step towards specialization was taken.

Following the success of the Wolf came a demand for a 60-70 b.h.p. engine and the Lynx and the Leopard (4 litres) were the answer. At the 1925 Show the Leopard II (4.4 litres) made

its appearance. Several commercialvehicle makers then began to offer Perkins units 35 alternatives to the petrol engines by which their chassis were normally powered, and in 1936 Vauxhall Motors, Ltd., listed it as

B24

available in its machines. for overseas. In the case of both the Commer and the Bedford, the Perkins Leopard II replaced a six-eylindered petrol job. Naturally, a few snags were, struck, but in every case these were soon rectified and the fine reputation that had already been gained was enhanced.

Up to 1935 progress had been steady both at home and abroad, the numbers of engines supplied for these two markets being approximately equal,. but the 1936 Budget constituted a serious setback. Home sales practically ceased. Further concentration, accordingly, was brought to bear on the overseas markets, and openings were found in South America, the West Indies, West, East and South Africa, India, Ceylon, Australia, New Zealand, and, nearer home, in Europe. Thus progress continued, but it was not until 1937 that there was a recovery in Great Britain.

Among the difficulties encountered was that of weight, the installation of the oil engine bringing the unladen vehicle lust outside

the 30 m.p.h. limit. Also, the Perkins engine was rougher, particularly at ticking-over speeds, than the petrol unit, and the price was an obstacle.

As a result, it was decided to add a light six-cylindered engine

to the Perkins range and to improve production methods. The former scheme. materialized in the P3, originally named the Panther, which was announced last summer, and the latter in laying down a really efficient assembly line.

Now the home trade is rapidly being regained, there is an oil " six " to replace a petrol" six," the former being no heavier, no larger, and more powerful. It is claimed that, in terms of power per sq. in. of piston area, the P6 is superior to any other commercialvehicle oil or petrol engine made. Moreover, the price is attractive.

The 50-50 home-to-export ratio is being approached once again, more agents in this country are being appointed, the works are being enlarged, and the number of men employed increased. A machine , shop is in course of being equipped which will be capable of handling sets of parts for 5,000 engines per year and a 32-acre site on the outskirts of Peterborough has been acquired against the day when a further extension is justified. To-day, the output averages 30-35 engines per week.

Each unit is run for seven hours before being passed out. There are 10 test beds for vehicle engines and, in addition, two for chassis shop five used vehicles in for conversion, one of a batch (so we were informed) of five new Leyland Cubs in which Perkins P6 units were being installed, six new Bedfords for equipment with P6 and Leopard H engines, and a new Chevrolet, which was being used for the operation of standardizing a Perkins conversion set for this make for export.

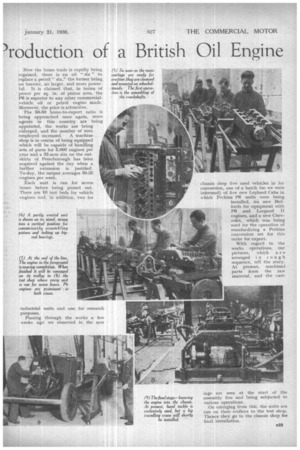

With regard to the works operations, our

pictures, which a r e -arranged in rough sequence, tell the story. At present, machined parts form the raw material, and the cast

ings are seen at the start of the assembly line and being subjected to various operations. On emerging from this, the units are run on their ,trolleys to the test shop. Thence they go to the chassis shop for final installation.