York talks on bodies

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

IN According to Jim Davies, managing director of York Trailer Holdings, York is now the country's largest body builder. The problem is, "probably no-one outside the York Group knows it".

If York is indeed the biggest bodybuilder in the UK, and there may well be a few other bodybuilders which will dispute it, how is it that nobody knows?

The answer could lie in the fact that, for most operators, York means trailers, and very little else.

Last year, however, York (part of the ever-expanding Bunzl Transportation empire) set itself up as a national rigid vehicle bodybuilder.

So what is new about that? There are after all, plenty of rigid body builders who already sell throughout the country. There, believes Davies, lies the subtle difference between his company's business, and the others, for York has established a national network of regional bodybuilders which all carry the York name.

The advantage of taking this route is that a truly 'local' bodybuilder can take advantage of the market that exists around dealers, which are often reluctant to send a chassis hundreds of miles to a larger big-name bodybuilder.

So far York's venture into the rigid bodybuilding market has got off to a rather quiet start. Four of York's Truck Equipment Centres — which previously concentrated solely on trailer servicing, spares and repairs — have now taken on additional rigid bodybuilding.

'The four, which have been renamed York Transport Engi neering sites to reflect their extra responsibilities are based at Glasgow, Warrington, Cannock and Watford.

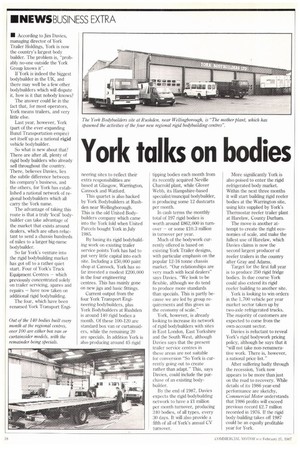

This quartet is also backed by York Bodybuilders at Rushden near Wellingborough. This is the old United Bodybuilders company which came into the York fold when United Parcels bought York in July 1985.

By basing its rigid bodybuilding work on existing trailer service points York has had to put very little capital into each site. Including a 250,000 paint shop at Cannock, York has so far invested a modest 2200,000 in the four engineering centres. This has mainly gone on new jigs and basic fittings.

Current output from the four York Transport Engineering bodybuilders, plus York Bodybuilders at Rushden is around 140 rigid bodies a month. Of these 100-120 are standard box van or curtainsiders, while the remaining 20 are specials. In addition York is also producing around 45 rigid tipping bodies each month from its recently acquired Neville Charrold plant, while Glover Webb, its Hampshire-based specialist/muncipal bodybuilder, is producing some 12 dustcarts per month.

In cash terms the monthly total of 197 rigid bodies is worth around 2862,000 in turnover — or some £10.3 million in turnover per year.

Much of the bodywork currently offered is based on existing York Trailer designs, with particular emphasis on the popular 12-16 tonne chassis market. "Our relationships are very much with local dealers" says Davies. "We look to be flexible, although we do tend to produce more standards than specials. This is partly because we are led by group requirements and this gives us the economy of scale."

York, however, is already looking to increase its network of rigid bodybuilders with sites in East London, East Yorkshire and the South West, although Davies says that the present trailer service centres in these areas are not suitable for conversion ''So York is currently going out to create rather than adapt." This, says Davies, could include the purchase of an existing bodybuilder.

By the end of 1987, Davies expects the rigid bodybuilding network to have a million per month turnover, producing 240 bodies, of all types, every 30 days. It will also provide a fifth of all of York's annual CV turnover. More significantly York is also poised to enter the rigid refrigerated body market. Within the next three months it will start building rigid reefer bodies at the Warrington site, using kits supplied by York's Therrnostar reefer trailer plant at Harelaw, County Durham.

The move is another attempt to create the right economies of scale, and make the fullest use of Harelaw, which Davies claims is now the second largest producer of reefer trailers in the country after Gray and Adams.

Target for the first full year is to produce 250 rigid fridge bodies. In due course York could also extend its rigid reefer building to another site.

York is looking to win orders in the 1,700 vehicle per year market sector taken up by two-axle refrigerated trucks. The majority of customers are expected to come from the own-account sector.

Davies is reluctant to reveal York's rigid bodywork pricing policy, although he says that it "will not take non-renumeralive work. There is, however, a national price list."

After suffering badly through the recession, York now appears to be more than just on the road to recovery. While details of its 1986 year-end performance are sketchy, Commercial Motor understands that 1986 profits will exceed previous record £2.7 million recorded in 1976. If the rigid body-building takes off 1987 could be an equally profitable year for York.