PROGRESS IN COMMERCIP -VEHICLE ENGINE DESIGN.

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Factors Which Have Had to be Considerec The Importance of Silent and Sm( Obtaining More Power from Smaller Units. It Running. Constructional Features.

WHENW o

one compares the commercial vehicle of to with that of only a few years ago the most striking differences usually observed are the speed and silence when running. In fact, so great has been the progress in both respects that the modern vehicle, and particularly that designed for the transport of passengers, is comparable with the private car ; some of the best are even an improvement on many cars in these points.

Many factors have entered. into the obtaining of this all-round betterment, and perhaps the most important is the modification carried out in engine design.. At one time, what may be termed general chassis noises were so great that a quiet, smooth-running engine was not really essential, but with the silencing of the rest of the chassis engine noise and vibration became of primary importance, and coupled with this was the demand for engines which would combine economy of fuel an.0 lubricant with the capacity for 'developing a high torque, and which, whilst developing adequate power at comparatively low speeds to give the steady pulling required on gradients that can be climbed on top gear, would give rapid acceleration and a power curve risingsteadily to 2,000 r.p.m. or more, The casual inquirer may well ask what important alterations in design can have been made to permit such improvements to be effected, and even to the technically minded the answer to such a question cannot be definite. Improvements have not resulted from radical changes, but from a close study of detail design and, in many instances, the incorporation of what might seem comparatively minor changes.

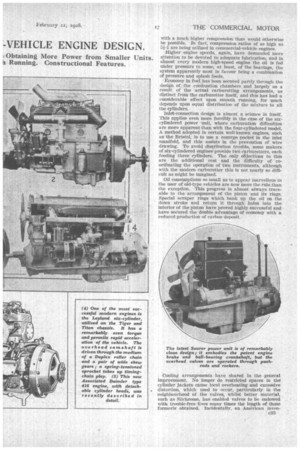

The obtaining of greater power from smaller engines called for more revolutions per minute. This, in turn, meant lighter reciprocating parts, better balance and easier flow, of gases to and from the valves.

The demand for further efficiency has also enforced the employment of higher compressions, and these have been rendered possible only by the securing of a much higher degree of turbulence, such as is afforded by the Ricardo design of cylinder head and other forms of what may be termed the wedge-shaped combustion chamber. At this point it may be mentioned that differences in the design of the combustion chamber exercise an extraordinary influence upon the combustion of the fuel, and a good design will permit an engine to run smoothly without any "pinking" and c32 with a much higher compression than would otherwise . be possible. In fact, compression ratios of as high as 54-1 are being utilized in commercial-vehtele engines.

Higher engine speeds, again, have demanded more attention to be devoted to adequate lubrication, and in almost every modern high-speed engine the oil is fed under pressure to some, at least, of the bearings, the system apparently most in favour being a combination of pressure and splash feeds.

Economy in fuel has been secured partly through the design of the combustion chambers and largely as a result of the actual carburetting arrangements, as distinct from the carburetter itself, and this has had ,a considerable effect upon smooth running, for much depends upon equal distribution of the mixture to all the cylinders.

Inlet-connection design is almost a science in itself. This applies even more forcibly in the case of the sixcylindered power unit, where carburation difficulties are more apparent than with the four-cylindered model. A method adopted in certain well-known engines, such as the Bristol, is to use a resurge pocket in the inlet manifold, and this assists in the prevention of wire drawing. To avoid distribution trouble, some makers of six-cylindered engines provide two carburetters, each feeding three cylinders. The only objections to this are the additional cost and the difficulty of coordinating the operation of two instruments, although with the modern carburetter this is not nearly so difficult as might be imagined.

Oil consumptions so small as to appear marvellous to the user of old-type vehicles are now more the rule than tile exception. This progress is almost always traceable to the arrangement of the piston and its rings. Special scraper rings which bank up the oil on the down stroke and return it through holes into the interior of the piston have proved highly successful and have secured the double advantage of economy with a reduced production of carbon deposit.

Cooling arrangements have shared in the general improvement. No longer do restricted spaces in the cylinder jackets cause local overheating and excessive distortion, which used to occur, particularly in the neighbourhood of the valves, whilst 'better material, such as Silchrome, has enabled valves to be endowed with trouble-free lives many times the length of those formerlv obtained. Incidentally, an American inven tion in this connection involves the internal cooling of valves by molten salt, which assists in dissipating the heat from the valve head.

We must not forget that great success is aLso being obtained from various types of engine employing sleeve valves, both single and double.

In the Daimler thin and light steel sleeves have replaced the cast-iron pattern formerly employed, whilst in the Panhard the steel valves are coated with white metal, thus avoiding all danger of scoring.

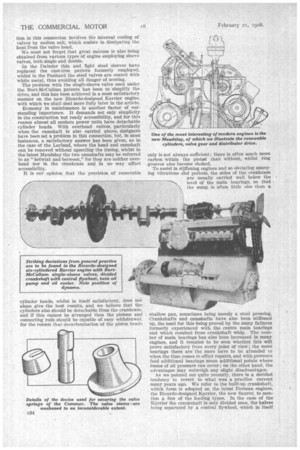

The problem with the single-sleeve valve used under the Burt-McCullum patents has been to simplify the drive, and this has been achieved in a most satisfactory manner on the new Ricardo-designed Karrier engine, with which we shall deal more fully later in the article.

Economy in maintenance is another factor of outstanding importance. It demands not only simplicity in the construction but ready accessibility, and for this reason almost all modern power units have detachable cylinder heads. With overhead valves, particularly when the camshaft is also carried above, designers have been set a problem in this connection, but, in most instances, a satisfactory answer has been given, as in the case of the Leyland, where the head and camshaft can be removed without upsetting the timing, whilst in the latest Maudslay the two camshafts may be referred to as "betwixt and between," for they are neither overhead nor in the crankcase and in no way affect accessibility.

It is our opinion that the provision of removable

cylinder heads, whilst in itself satisfactory, does not alone give the best results, and we believe that the cylinders also should be detachable from the crankcase, and if this cannot be arranged then the pistons and connecting rods should be capable of easy withdrawal, for the reason that decarbonization of the piston head,: only is not always sufficient ; there is often much more carbon within the pistod than without, whilst ring groeves also become choked.

To assist in stiffening engines and so obviating annoying vibrations Aid periods, the sides of the crankcase are usually carried well below the level of the main bearings, so that the starm is 'often little else than a shallow pan, sometimes being merely a steel pressing. Crankshafts and camshafts have also been stiffened up, the need for this being proved by the many failures formerly experienced with the centre main bearings and which resulted from crankshaft whip. The manber of main bearings has also been increased in many engines, and it remains to be seen whether this will prove satisfactory from every point of view ; the more bearings there are the more have to be attended to when the time comes to effect repairs, and with pressure feed additional bearings mean additional points where losses of oil pressure can occur ; on the other hand, the advantages may outweigh any slight disadvantages.

As we pointed out quite recently, there is a decided tendency to revert to what was a practice current many years ago. We refer to the built-up crankshaft, which form is adopted on the latest Dorman engines, the Ricardo-designed Karrier, the new Saurer, to mention a few of the leading types. In the case of the Karrier the crankshaft is onlY divided once, the halves being separated by a central flywheel, which in itself

forms a striking deviation from standard practice and one which does much to reduce torsional stresses on the shaft We do not propose to enter into a discussion upon the merits or demerits of various methods of fitting big-ends, as this subject has ireally been threshed out in our columns. We may point out, however, that there is a decided tendency towards the adoption of the twobolt big-end, and with the modern materials which are available there appears to be no objection on the score of reliability and the fitting is simplified to a considerable degree. Even for main bearings, the two-bolt method is, in some instances, being adopted for the caps, as with the latest Associated Daimler unit. which we described only a few weeks ago.

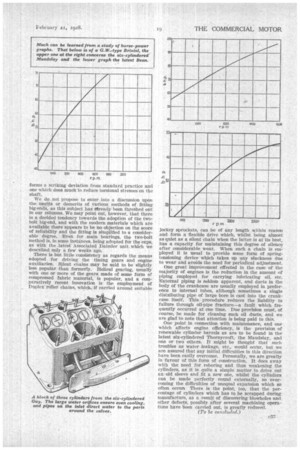

There is but little consistency as regards the means adopted for driving the timing gears and engine auxiliaries. Silent chains may be mid to be slightly less popular than formerly. Helical gearing, usually with one or more of the gears made of some form of

compressed fabric material, is popular, and a comparatively recent innovation is the employment of Duplex roller chains, which, if carried around suitable jockey sprockets, can be of any length within reason and form a flexible drive which, whilst being almost as quiet as a silent chain when the latter is at its best, has a capacity for maintaining this degree of silence after considerable wear. When such a chain is employed it is usual to provide some form of springtensioning device which takes up any slackness due to wear and avoids the need for periodical adjustment.

One great improvement effected in the ease of the majority of engines is the reduction in the amount of piping employed for carrying lubricating oil, etc. External piping is seldom apparent, and ducts in the body of the crankcase are usually employed in preference to internal tubes, although sometimes a single distributing pipe of large bore is cast into the crankcase itself. This procedure reduces the liability to failure through oil-pipe fracture—a fault which frequently occurred at one time. Due provision must, of course, be made for cleaning such oil ducts, and we are glad to note that attention is being paid to this.

One point in connection with maintenance, and one which affects engine efficiency, is the provision of renewable cylinder barrels as are to be found in the latest six-cylinclered Thornycroft, the Maudslay, and one or two others. It might be thought that such troubles as water leakage, etc., would occur, but we are assured that any initial difficulties in this direction have been easily overcome. Personally, we are greatly in favour of this form of construction. It does away with the need for reboring and thus weakening the cylinders, as it is quite a simple matter to drive out an old sleeve and fit a new one, whilst the cylinders can be made perfectly round externally, so overcoming the difficulties of unequal expansion which so often occure There is the point, too, that the percentage of cylinders which has to be scrapped during manufacture, as a result of discovering blowholes and other defects, possibly after several machining operations have been carried out, is greatly reduced.