FARMING

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

BY

FORD.

The Conversion Unit and the Small Farmer.

WHY CANNOT I put my car to work on the land? I do not want it on the Toad all the

. time ! Such is the cry we have often heard while discussing the problem of the motor exploitation of the land with mall farmers. Many of these yeomen have invested in a Ford car to enable them to complete .their business expeditiously, but the time occupied in this essential duty on the high Toad represents but a. trifling fraction in the working day. For the greater part of its time the ear is standing idle. Now as the, farmer abhors allowing his horse to rusticate in its stable, eating its head off, so does he . deplore his motor resting in its garage for hour after hour. True the vehicle, unlike the horse, incurs no expense While standing dormant, but to the farmer it. represents a potential source of power running to seed from lack of work. • , It must be admitted that no phase of the power farming issue makes such strong appeal tO the small fanner as the presentation. of ways and means whereby he can turn his Ford into a 100 per cent. motor unit. He realizes that any such Itpplication must follow the lines of an improvisation or attachment, but this con, sideration is immaterial so long as the process of converting the vehicle from one duty to the other is net intricate or lengthy to complete.

From the mechanical point of view the issue assumes a different aspect. There is no disputing the ability of the popular Ford to draw a Wn-furrow plough through the heaviest land. The 20 h.p. developed by the four-cylinder engine is adequate for thepurpose. The question is how to apply this source of energy in the most efficient manner.

Two or three sound efforts in this direction have been made. Such a one is the Eros, marketed by Morris, Russell and Co., Ltd., 75, Curtain Road, London, E.C. Of American design, this adaptation has proved successful in.-the land of its origin. The system has been previously described in these pages, and a few days ago we-were extended the opportunity to see the outfit at work. The conversion unit, which is of substantial design, an be attached and detached in about 30 minutes while it follows such lines as to reduce the strains and stresses upon the car to the minimum, except, possibly, the low gear.

The task imposed upon the latter varies with the character of the land and the furrow. In the operations we witnessed, owing to the adverse conditions of working upon rain-soddened, undrained, tough, old lea, the installation was submitted to a particulaily exacting test. But when a suitable plough, properly adjusted, was hitched, to the car the breaking of the land was convincingly satisfactory. The furrow was cleanly cut and the slice neatly turned and well laid over, as may be judged from the illustration on the preceding page.

This demonstration served to emphasize the significance of the plou. The implement which gave the best all-round showing was the Eros two-furrow selflifter, which is of British design and construction throughout. It may be best described • as a sound blacksmith's job, being of sturdy, simple construction, and representing the minimum of departure from proved British practice applied to, power. The selflifting arrangement is likewise ofa straightforward simple character, free from easy derangement.

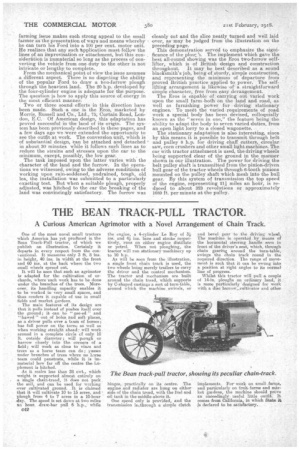

The Eros is capable -of carrying out Varied work upon the small farm both on the land and road, as • well as furnishing power for driving stationary engines. To meet the varied requirements of road work a special body has been devised, colloquially known as the "seven in one," the feature being the ability to adaptthe body to seven varied duties, from an open light lorry to a closed wagonette.

The stationary adaptation is also .interesting, since by this means it is possible to transmit through belt and pulley 8 h.p. for driving chaff cutters,. circular saw, earn crushers and other small light maclunes. The car with tractor attaohment is used, the driving wheels being supported clear of the ground in the manner shown in. our illustration. The power for driving the belt pulley shaft is transmitted from the pinion-driven bull gear of the tractor wheels through 6-tooth pinions mounted on the pulley shaft which mesh into the bull gear. By this system of transmission -the top speed of the engine, representing 21:1 miles an hour, is reduced to about 323 revolutions or approximately . 1689 ft. per minute at the pulley.