Chassis Construction in the North Country.

Page 3

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

The Heavy Motor Section of the Armstrong-Whitworth Works is approaching compIetior.

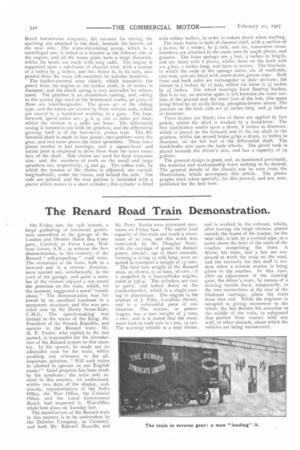

The fact that the construction of heavy motors is capable of giving a good return, upon the capital laid out, is evidenced by the entry of so many large, general-engineering companies upon the building of motorbus and lorry chassis : the extension is, certainly, worthy of their attentions. Numerous companies, whose speciality requires a large plant of heavy machinery, are in an excellent position to do, with quickness and despatch, the operations on the various parts which go to form a self-propelled vehicle. Again, if a special plant has been laid down, it is, always, possible, in a large undertaking, to pass some of the parts to one of the other shops for completion. In this way, quick delivery can, generally, be obtained, even when times of pressure occur in the legitimate motor departments. The foregoing remarks apply to Sir W. G. Armstrong, Whitworth and Company, Limited, of Newcastle-on-Tyne. This colossal engineering works covers, practically, a wide strip of land, on one of the banks of the River Tyne, no less than three miles long. The real significance of this statement can be appreciated, only, by one who has seen the endless succession of buildings, and machinery, and has made his way through the labyrinth of the main thoroughfares, either on foot, or by one of the numerous staff cars which, constantly, pass one, and which bear on their platforms some portion of light machinery, or castings, in course of transportation from one department to another. All the shops are connected to one another, by a railway, and this has branch lines wherever needed. The company does not, at the present time, contemplate the bringing out of standard commercial chassis of its own, but its programme will be confined to the construction of vehicles, in quantities, to the order, and design, of the purchaser. It would be superfluous for the writer to enter upon the subject of 9uality of material, and he will, at once, pass a few descriptive re marks upon the new motor shops, which are situated at Scotswood, the westerly extremity of the buildings. Two s' ops have, so far, been erected : the first of these has a ground area of nearly 14,400 square feet, and will contain the machine tools; these are, temporarily, placed in a gallery which will, eventually, contain a certain number of the smaller machines. The gallery is, therefore, congested to such an extent that full advantage cannot be taken of many of the tools. This trouble will, speedily, be rectified, as the shop is near completion.

The second building is one of six units; others will be built as required, the one in course of erection having a floor area of about 7,875 square feet. This shop has no gallery, and it is, now, being used for the assembling of different vehicles, as by our full-page illustration. The writer examined one of a number of bus chassis, which are being brought through the shops to the order of a large company in London, and this vehicle will be described later in the article. When the plant in the machine shop is properly arranged, it will be possible to turn out about six bus, or lorry, chassis per week, in addition to the pleasure cars which the company has been making for about three years. The standardisation of parts, and the machining to limits, which methods have been brought to a high standard in the company's ordnance sections, will be adopted in the building of motors, and absolute interchangeability of all machine work will be guaranteed. Numerous, and expensive, jigs have been made for the orders in hand, and these are stored, carefully, for use on repeat orders of the same design.

An interesting feature in the economic distribution of the different processes, is the employment of about three hundred girls, who work in a shop which is fitted with machines —capstan lathes, and other tools—for the production of small bolts and nuts, The company makes most of the steel used ; there are, also, separate foundries for steel, brass, and aluminium. The laboratories are spacious, and employ a large staff of chemists. The making of artillery wheels, for the chassis under construction, is, also, undertaken, and these are brought through in the same section where the wheels of gun carriages, etc., are built. The motor patternshop is a small branch of the larger one, where about soo men are to be seen.

One of the most interesting points, in the organisation of the works, is the fire brigade. A stall of 5o men is kept, and there is a head station, and five sub-sta

tions. All the stations are fitted with fire escapes, and other tackle, whilst the head station is equipped with two selfpropelled vehicles; one of these is a fire escape, and the other carries everything that can., be required to cope with a conIlagration.

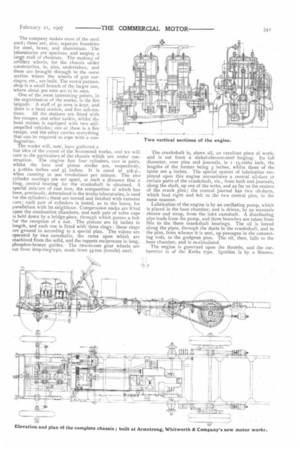

The reader will, now, have gathered a fair idea of the extent of the Scotswood works, and we will turn to the particulars of the chassis which are under construction. The engine has four cylinders, cast in pairs, whilst the bore and piston stroke are, respectively, 4 5-16ths inches and 5i inches. It is rated at 32h.p., when running at goo revolutions per minute. The two cylinder castings are set apart, at such a distance that a long, central bearing for the crankshaft is obtained. A special mixatre of cast iron, the composition of which has been, previously, determined in the works laboratories, is used for the cylinders; these are turned and finished with extreme care ; each pair of cylinders is tested, as to the bores, for parallelism with its neighbour. Compression cocks are fitted upon the combustion chambers, and each pair of valve caps is held down by a bridge-piece, through which passes a bolt for the reception of a nut. The pistons are 6i inches in length, and each one is fitted with three rings these rings are ground in according to a special plan. The valves are operated by two camshafts, the cams upon which are machined from the solid, and the tappets reciprocate in long, phosphor-bronze guides. The two-to-one gear wheels are cut from drop-forgings, made from 45-ton (tensile) steel.

The crankshaft is, above all, an excellent piece of work, and is cut from a nickel-chrome-steel forging. Its full diameter, over pins and journals, is x 15-16ths inch, the lengths of the former being 3 inches, whilst those of the latter are 4 inches. The special system of lubrication employed upon this engine necessitates a central oil-duct at certain parts of the crankshaft, viz., from both end journals, along the shaft, up one of the webs, and as far as the centres of the crank pins; the central journal has two oil-ducts, which lead right and left to the two central pins, in the same manner.

Lubrication of the engine is by an oscillating pump, which is placed in the base chamber, and is driven, by an eccentric sheave and strap, from the inlet camshaft. A distributing pipe leads from the pump, and three branches are taken from this to the three crankshaft bearings. The oil is forced along the pipes, through the ducts in the crankshaft, and to the pins, from whence it is sent, up passages in the connecting rods, to the gudgeon pins. The oil, then, falls to the base chamber, and is re-circulated.

The engine is governed upon the throttle, and the carburetter is of the Krebs type. Ignition is by a Simms Bosch low-tension magneto; the cut-outs for testing the sparking are attached to the dash, beneath the bonnet, on the near side. The water-circulating pump, which is a centrifugal one, is bolted to a bracket at the exhaust side of the engine, and all the water pipes have a large diameter, whilst the bends are made with long radii. 1 he engine is supported upon a sub-frame of channel secei, with a section of 2 inches by 3 inches, and this frame is, in its turn, suspended from the main side-nu:inhere by suitable brackets.

The leather-covered cone clutch, which transmits the power from the engine to the cardan shaft, is 18 inches in diameter, and the clutch spring is very accessible for adjustment. The gearbox is an aluminium casting, and, owing to the special jigs used at the Scotswood works, all parts of these are interchangeable. The gears are of the sliding type, and the ratios are altered by three selector rods, which are moved by a hand-lever working in a gate. The four, forward, speed ratios are : 3, 6, 9, and 12 miles per hour, whilst the reverse is 3 miles per hour. The differential casing is formed in one with the gearbox, and the differential gearing itself is of the four-bevel, pinion type. The differential shaft is made in four pieces : two portions carry the gear, and two outer pieces the chain sprockets. These outer pieces revolve in ball bearings, and a square-head and socket joint is employed to drive them from the inner members of the shaft. Side chains are used for final transmission, and the numbers of teeth on the small and large sprockets are, respectively, 15 and 43. The radius rods, by which the tension of the chains is adjusted, are carried, longitudinally, under the frame, and behind the axle. The rods are jointed, and the rear portion is furnished with a piston which moves in a short cylinder; this cylinder is fitted

with rubber buffers, in order to reduce shock when starting.

The main frame is built of channel steel, with a section of 5 inehes, by 2 inches, by I inch, and six, transverse crossmembers are attached to the main ones by angle pieces, and gussets. The front springs are 3 feet, 3 inches in length, and are fitted with 8 plates, whilst those on the back axle are 4 feet, 2 inches long, and have ii leaves. The brackets, in which the ends of the springs move, arc of malleable, cast iron, and are fitted with screw-down grease cups. Both front and back axles are rectangular in their sections; the former is 3 inches, by rq inch, whilst the latter is 3,1 inches by :4 inches. The wheel bearings have floating bushes, that is to see, an annular space is left between the outer suie face of the journal and the inner face of the hub, this space being fitted by an easily-fitting, phosphor-bronze sleeve. The journals on the back axle are 94 inches long, and 3Ainches in diameter.

Three brakes are fitted; two of these are applied by foot pedals, whilst the third is worked by a hand-lever. The first foot-brakes works upon a drum, 8 inches in diameter, which ie placed on the forward end of the lay shaft in the gearbox, whilst the second brake grips a drum, 12 inches in diameter, on the left half of the differential shaft. The hand-brake acts upon the back wheels. The petrol tank is placed beneath the driver's seat, and has a capacity of 25 gallons. The general design is good, and, as mentioned previously, the material and workmanship leave nothing to be desired. The general details of the chassis can be seen from the illustrations, which accompany this article. The photo.. graphs were taken speeially, for this journal, and are, now, published for the first time.