For DRIVERS MECHANICS & FOREMEN

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is _paid to the sender of any letter which we publish on this page, and an EXTRA FIVE SHILLINGS to the sender of the one which we select as being the best each week.All notes are edited before being published. lifention your emploor's name, in confidence, as evidence of good faith. Address, D. M. and F., "The Commercial Motor," 7-15, Rosebery Avenue, London, EX, 1.

amps Alight.

On Saturday, December 25th, light your lamps at 23 in London, 4.11 in Edinburgh, 4.10 in Newcastle, 23 in Liverpool, 4.24 in Birmingham, 4.33 in Bristol, nd 5.8 in Dublin.

.sks Help.

he sender of the following communication has been awarded the extra payment of Sc. this week,.

[2,169] " Worried Driver" (Lewisham) writes I we had a lot of trouble with a two-cylinder-engined rry.of well known make, and am writing this letter the hope that it will be read by other drivers who ill give me the benefit of their advice and assistance. he lorry is a Thornycroft, and if those who have had Eperience of this make and type would write to your Aper concerning the following difficulty, I should b6

ry grateful. I am a driver of 10 years' experience, d have been driving this particular machine during

e last four years.

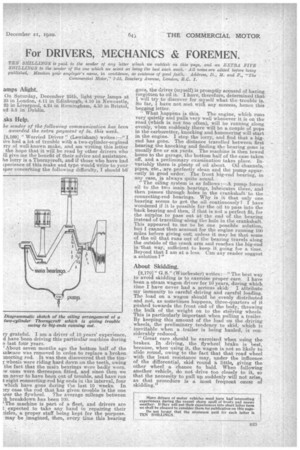

'About seven months ago the bottom half of the inkcase was removed in order to replace a broken meeting rod. It was then discovered that the timwheels were riding hard down on the teeth, owing the fact that the maii bearings were badly worn. av ones were thereupon fitted, and since then we im never to have been out of trouble, and have run eight eennecting-rod big ends in the interval, four which have gone during the last 10 weeks. In 3ry case the rod that has given trouble is the one ),rer the flywheel. The average mileage between ..:11 breakdown has been 100.

'The machine is part of a fleet, and drivers are t expected to take any hand in 'repairing their skies, a proper staff being kept for the purpose. may be .imagined, then, every time this bearing

goes, the driver (myself) is promptly accused of having forgotten to oil it. I have, therefore, determined that I will trY to discover for myself what. the trouble is. So far, I have not met wits any success, hence this begging letter.

" What happens is this. The engine, which runs very quietly and pulls very well whenever it is on the road (which is not too often), will be running along evenly, when suddenly there will be a couple of pops in the carburetter, knocking and hammering will start in the engine. I stop the lorry, and. find that a bigend has gone. The distance travelled between first hearing the knocking and finding the bearing gone is usually five or six yards. The machine is then towed house to the garage, the bottom half of the case taken off, and a preliminary examination takes place. Invariably there is plenty of oil about. Oil channels, pipes, etc., •are perfectly clean and the pump. apparently in good order. The front big-end bearing, in any case, is always quite sound. "The oiling system is as follows :—A pump forces oil to the two main bearings, lubricates these, and then passes through holes in the cranksha.ft to the connecting-rod bearings. Why is it that only one bearing seems to get the oil continuously ? I have wondered if it is possible for the oil to pass into the back bearing and then, if that is not a perfect fit, for the surplus to pass out at the end of the bearing instead of travelling-along-the hole in the crankshaft. ThiS appeared to me to be one possible solution, but I cannot then account for the engine running 100 • miles before giving out; unless it may be that some of the oil that runs out of the bearing travels along the outside of the crank arm and reaches the big-end in -that way, sufficient to keep it going for a time. Beyond that I amat a loss. Can any reader suggest

a solution?" •

About Skidding.

12,170] " G.S." (Winchester) writes " The best way to avoid skidding is to exercise proper care. I have been a steam wagon driver for 10 years, during which time I have never had a serious skid: I attribute my immunity to careful driving and careful loading. The load on a wagon should be evenly distributed and not, as sometimes happens three-quarters of it pushed towards the front end of the body, throwing the bulk of the weight on to the string wheels. This is particularly important when pulling a trailer. By keeping this amount of the load on the driving wheels, the preliminary tendency to skid, which is inevitable when a trailer is being hauled, is considerably reduced.

"Great care .should be exercised when using the brakes. In driving, the flywheel brake is best, because, when using it, the wagon is not so likely to slide round, owing to the fact that that road wheel with the least resistance may, under the influence of the differential, skid round a little, giving the other wheel a chance to hold. When following another vehicle, do not drive too closely to it, so that the necessity to pull up suddenly will not arise, as that procedure is a most frequent cause of skidding."