LOW-LOADING ADVANTAGES.

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

Why Platform Heights Could Profitably be Lowered Generally. Special Loading Lines for Special Purposes.

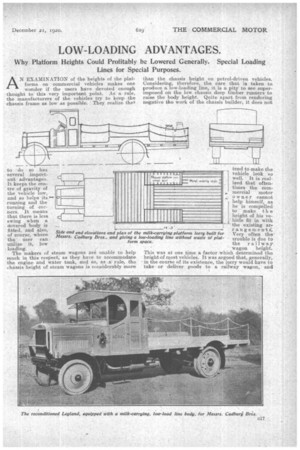

AN EXAMINATION of the heights of the platforms on commercialvehicles makes one• . . wander if the users have devoted enough thought to this very important point. AS a rule, the manufacturers of the vehicles tryto keep the chassis frame as low as possible. ' They realize that to do so has Several important advantages. It. keeps the centre of gravity of the vehicle low, and BO helps -its .= running and the turning of corners. It means that there is less swing when a ciovered body is fitted, and also, of course, where the user canutilize it, low . loading.

The makers of steam wagons are unable to help much in this resPect, as they have to accommodate the engine and water tank, and so, as a ride, the chassis height. of steam wagons is considerably more than the chassis height on petrol-driven vehicles. Considering, therefore, the care that is taken to firocluce a low-loading line, it is a pity to. see superimposed on the low chassis deep timber runners to raise the body height. Quite apart from rendering negative the work of the chassis builder, it does not

tend to make the vehicle look so well. It is realized that oftentimes the commercial motor Owner cannot help himself, as , he is compelled to make the height of his vehicle fit in with the existing arrangeme nt S. Very often the trouble is due -to the railway

wagon height. This was at one time a factor which determined the height of most vehicles, it was argued that, generally, in the course of its existence, the lorry would have to take. or deliver goods • to a railway wagon, and

-therefore, it was made approximately this height. Fr the same reason the loading docks in factories were madeto correspond. When motors are first -used it is the line of least resistance to make them the height to correspond with the docks. Thesquestion is: hit, really necessary and are we bound to follow the slavish practice started by horse lorries' to conform with railway trucks 1r We, know that it was done with army lorries, but, of course, these had definitely to work from the rail head, and it was-possibly the best arrangement in their ease.

Allusionyhas already been made to horse vehicles, which were usually made a standard height to suit the railway wagons. Even with these, however, there were exceptions. It has long been recognized that in the case of pigs, fer instance, a special vehicle is the best, and we get the pig float with an exceptionally low floor, so that the pigs can be driven straight in.

The argument we are trying to develop is that what ;Jas been done to some 'extentfin the case of horse vehicles may be done even more with motor vehicles, and that we should have more single-purpose vehicles. We quite realize this in the engineering industry.. No manufacturer's works are equipped solely/with universal lathes ; there are capstan lathea and ether single-purpose lathes for special jobs. This is what should be done with motor, vehicles.They. should be designed specially for the job they have to carry out, and theplatform height should be made as lew-as possible, _other things being equal.

Advantage of Low Loading. •

The advantages of a low-loading line a-re fairly obvious. Assuming the goods have to be lifted from the ground, the height to be lifted is much less, and consequenfly the amount of work which has to be done by the driver and his man is reduced. This means that the lorry is leaded in quicker time and there.

018 is less risk of hernia occurring to the men who are lifting the goods ; the prevalence of this class of accident among men employed on loading and unloading lorries is such is to call for some reform in this direction.

Where a lorry is fitted with a low body, the advantageg},;in driving are considerable. The chaver looking out through the window at the back of his cab has a clearer vision and, as previously stated, he feels less sway and difficulty in tuining corners; in unloading there is less drop for the goods. These who have noticed theunloading of horse and motor vehicles during the last few years will have seen that the general practice is to pull the cases of goods to the edge of the lorry and then let them drop. It seems impossible to persuade carters to unload by any other means and it is undoubtedly an advantage, so long as they do thig, to reduce the height from which the goods have to drop. _

The trouble, when goods are dropped like this, is not only that the contents may be broken, but that the case is often split open, rendering more likely the liability to theft. Many firms have been compelled to go in for costly boxes because of the damage which ha-s oocurred in this direction.

Special Applications.

In the collection of milk, a low loading platform is very advantageous ; lorries fitted up in this way for unloading have been described and illustrated in these pages. We show on page 629 an outline drawing of a body designe-d for a 4 ton reconstructed W.D. Leyland. It has boxes over the wheel which carry a certain number of churns and enable the rest of the body to be dropped down to the level -of the chassis.

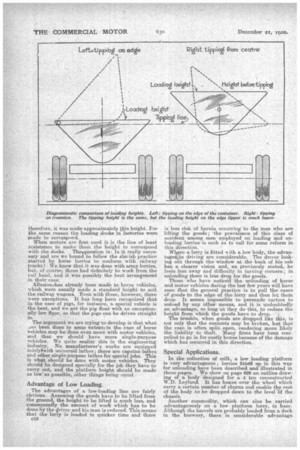

Another commodity, which can also be carried advantageously on a low platform lorry, is beer. Although the barrels are probably loaded from a dock in the brewery, there is considerable advantage found in unloading from a low body. There is less slope, and the barrels can be handled with less men. In the case of milk and agricultural preduce, much of this has to be lifted from the ground. We have already alluded to the pig cart, and we know that special motor horse-boxes have already been designed. Most veMcles employed on this work are now furnished with tipping bodies. While these are very satisfactory for unloading, they have the drawback of increasing the height to which the aefuse has to he thrown. Although introducing difficulties in connection with the weight an the edge of the chassis, one is inclined to suggest that ultimately designers will consider a tipping body which tips on the edge something like the design of a mixer well known in the chemical and bakery trades. The outline sketches show what is meant. As will be seen, this will throat the weight on the side of the chassis, but if the tipping body were made in two or three parts, the weight would be more evenly distributed, and, no doubt, any disability in this direction would be overcome. This would reduce the height considerably over bodies which tip on trunnions or from the centre, while still tipping at the same height. The great trouble with refuse collection is the loading, and one is inclined to think thatadesigners will eventually incorporate something of the elevator type, so that the men will throw into the boot of an elevator situated quite close to the ground, and the refuse saill be taken up by scrapers or buckets and distriboted into the tipping body.

It will be gathered from the above that what we wish to suggest is that, users of commercial vehicles should not be bound to existing arrangements, but should endeavour to get the very best out of their vehicles by studying body as well as chassis design. To do this, they should be prepared to modify the lay-out of their factory or premises, to consider the adoption of devices which have been found useful in other spheres of industrial activity, -and, wherever possible to take advantage of the low loading line, which is now provided by many chassis makers, who have realized that considerable scope for improvement lies in this direction.