AN ENTIRELY NEW STEAM WAGON.

Page 12

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

A Notable Addition to the List of Overtype Vehicles by Ransomes, Sims and jefferies, Ltd.

THERE is a number of interesting filit controversial matters in connection with commercial motor vehicles concerning which it almost ,

appears that we shall never reach any. definite conclusion, favouring one side or the other. ' Such a one • The last time we described a new steam wagon in these columns We had to record a ineetmg of east and west, for a, maker of over-type steam wagons was producing an undertype, in the same works. This week we have to register another addition to the ranks of makers of over-type steam wagons, a maker• of considerable experience in. other forms of mechanical road transport, particularly steam, but also electric, a maker who claims to have put a steam passenger vehicle on the road in 1871, and who, atleast, is one of the oldest firms engaged in this class of business, be ing established in 1784. 'Ws are referring to Ran sornes, Sims and Jefferies, of Orwell Works, Ipswich, whose new model steam wagon was shown at Olym pia and was again exhibited • last week in the Agricultural Hall at the aim Agricultural Hall at the aim ual Smithfield Show, attracting much attention. '012 The latest product of this well-imown concern

five-tonner. It is a characteristic over-type ste. wagon, but, both as regards its general design a as regards the details of its construction, it mai another step forward in the advance towards perf tion in respect of this class of vehicle. While, type, it is familiar, and one might almost say o fashioned in detail, it exemplifies the • most Mod(

practice and embodies i latest experience in au mobile engineering.

A Pressed Steel Boil The boiler isa fine 4 ample of the cornbin efforts of the pressing st and the boiler shop. had very brief ref erer in our "Patents Page " the issae dated Noveml 16th, the patentees bei Ruston and Hornsby, Lt with whom, as is known, Ransomes, Si

i

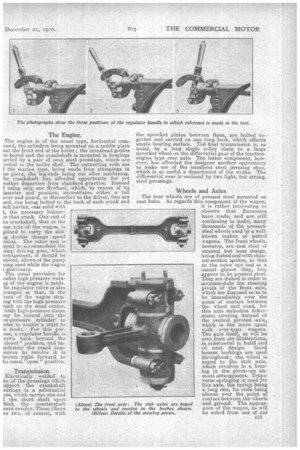

and Jefferies are n ci nection. It is construel from four pieces of ph only. The shell is made two halves, So that they j, round the vertical and 1, gitidinal centre line of I nailer. The joint is ale Joint, the strap bng 'side the boiler, and it finished off by electri welding. Thethird pli forms the fire-box; whict pressed out in one -pi( with .a domed top, thus minating the need i crown stays. The foil] plate is the front tube ph of the boiler; it is dish, and riveted to the shell the well-known mann There are 46 in. tub five of them being st 'tubes. It is con,strucl for a working pressure .225 lb. per square inch, I is tested hydraulically ti -much higher pressure.

The Engine.

The engine is of the usual type, horizontal cornamid, the cylinders being mounted on a saddle plate ear the front end of the boiler ; the crosshead guides re bored and the crankshaft is mounted in bearings arried by a pair of neat steel pressings, which are Lveted to the boiler shell. The connecting rods are f the marine type, being made from stampings in ne piece, the big-ends being cut after machining. he crankshaft has afforded opportunity for yet nother departure from standard practice. Instead f using only one flywheel, which, by reason of its iameter and position, necessitates either a tall over and guard, or discomfort to the driver, two are sed, one being bolted to the back of each crank and nth having, cast solid with

t, the necessary balance Dr that crank. One end of he crankshaft, that at the ear side' of the wagon, is plined, to carry the slidig double change speed

• inion. The other end is eyed to accommodate the Limp • driving gear, which rrangement, it should be oticed, allows of the pump eing Used while the wagon stationary. The usual provision for ouble high-pressure workig of the engine is made. he regulator valve is also rranged so that, in. the Vent of the wagon • stoping with the high-pressure rank on the dead centre, little high-pressure steam lay be turned into the )w-pressure cylinder in rder to enable a start to e made. For this purose, a regulator 'handle is rawn back beyond the closed " position, and imiediately the crank owniences to revolve it. is brown • right forward to ha usual "open " position.

Transmission. '

Electrically welded to ne of the pressings which aPport the crankshaft earings is a substantial oss, which carries one end f the short shaft u_pon rhich the couritershaft ears revolve. These (there re two, of course), with the sprocket pinion between them, are bolted together and carried on one long bush, which affords ample bearing surface. The final transmission is, as usual, by a long single roller chain to a large sprocket wheel on the differential gear of the tractionengine type rear axle. The latter component, however, has afforded the designer another opportunty to make use of the excellent steel pressing shop, which is se useful a department of the works. The 41ifferentia1 gear is enclosed by two light, but strong, steel pressings.

Wheels and Axles.

The rear Wheels are of pressed steel mounted on cast hubs. As regards this component of the wagon,

it is rather interesting to observe that Ransomes h-ave made, and are still continuing to make, many thousands of the pressedsteel wheels used by a wellknown maker of petrol wagons. The front wheels, however, are cast steel of unusual but neat design, being dished and with channel-section. spokes, so that to the outer eye and at a easual glance they, too,appear to be pressed steel. They are dished in order to accommodate the steering pivots of the front axle, which are disposed so as to be immediately over the point of contact between the wheel and road, for this axle embodies Ackermann steering instead of the central pivoted axle,_ which is the more ueual with over-type wagons. The axle itself, as will be seen from our illustrations, is substantial in build and of neat design. Good bronze bushings are used throughout ; the wheel is keyed to the Stub axle, which revolves in a bearing in the pivot—an unusual arrangement. Transverse springing -.s used for this axle, the spring being • a long one, its ends being almost over the point of contact between the wheels and ground. The appearance of the wagon, as will • be noted, from one of our

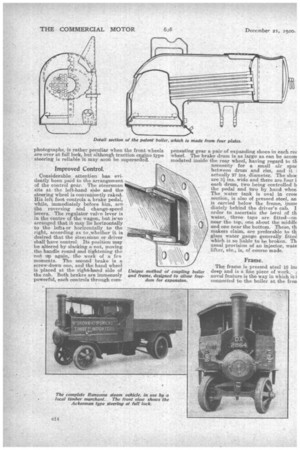

Improved Control.

Considerable attention h-a,s evidently been paid to the arrangement of the control gear. The steersman sits at the left-hand side and the steering wheel is conveniently raked. His left foot controls a brake pedal, while, immediately before him, are the reversing and change-speed levers. The regulator valve lever is in the centre of the wagon, but is'so arranged that it may, lie horizontally to the leftk or horizontally to the right, according as to whether it is desired that the ateei.sman or driver shall have control. Its position may be altered by slacking anut, moving the handle round and tightening the nut op again, the work of a few moments. The second brake is a screw-down one, and the handwheel is placed at the right-band side of the, cab. Both brakes are immensely powerful, each controls through com

pensating gear a pair of expanding shoes in each rez wheel. The brake drum is as large as can be accon modated inside the rear wheel, having regard to th necessity for a small air spac between drum and 'rim, and it i actually 27 ins_ diameter. The shoe are 31 ins, wide and there are. four i each drum, two being controlled b the pedal and two by hand .whee The water tank is oval in eras! section, is also of pressed steel, an is carried below the frame, ilium diately behind the driver's cab. I order to ascertain the level Of th

water,taps are fitted—on near the top, one about the middle and one near the bottom. These th makers claim, are preferable to th glass water gauge generally fitted which is so liable to be broken. Th usual provision of an injector, wate lifter, etc., is, of course made.

Frame.

The: frame is pressed steel 40 inE deep and is a fine piece of work_ 1 novel feature is the way in which it i connected to the boiler at the iron

end. It is there trimmed up squarely; so that it slides into brackets bolted to the boiler.. There is no positive connection between the frame and boiler at this end, but the former is free to slide, and' thus accommodate itself to the expansion and contraction of the boiler under heat. As a matter of fact, the front end of the boiler slides on the frame.

Specification.

We give below a few of the leading dimensions of this new chassis:—

The compound engine has cylinders of bore and stroke 4 ins. by 7 ins. high pressure, and 7 ins. by 7 ins, low pressure, The boiler pressure is 225 lb. pei sq. in., and the engine speeds and gear ratios

are such that on top gear the wagon travels at approximately 8 m.p.h., with the engine running at the normal rate, while on low gear the road speed is 31. m.p.h., the same condition prevailing as regards engine speed.

The travelling speeds are not, of c6urse, limited to this except in so far as the law affects them. Incidentally, this wagon is so constructed that, with five tons distributed in any reasonable manner over the standard body space, the rear axle weight is less than 8 tons. This is in part due to the Ackermann front .axle, which can be brought more to the rear than one which is centrally pivoted. The tyre sizes are 850 mm. by 160 mm., on the front wheels, and 1,050 mm. by 160 mm. (twin) on the rear. The overall length of the chassis is 21 ft. 8 ins., and width 7 ft.