New Bicera Blower is Simple and Effective

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

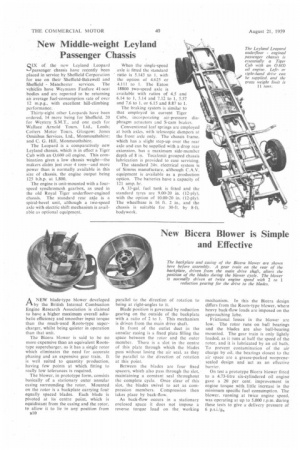

ANEW blade-type blower developed by the British Internal Combustion Engine Research Association is claimed to have a higher maximum overall adiabatic efficiency and smoother input torque than the much-used Roots-type supercharger, whilst being quieter in operation than that unit.

The Bicera blower is said to be no more expensive than an equivalent Rootstype supercharger, as it has a single rotor which eliminates the need for accurate phasing and an expensive gear train. It is well suited to quantity production, having few points at which, fitting to really low tolerances is required.

The blower, in prototype form, consists basically of a stationary outer annular casing surrounding the rotor. Mounted on the rotor is a backplate carrying foulequally spaced blades. Each blade is pivoted at its centre point, which is equidistant from the casing and the rotor, to allow it to lie in any position from

BT (I parallel to the direction of rotation to being at right-angles to it.

Blade position is governed by reduction gearing on the outside of the backplate with a ratio of 2 to I. This mechanism is driven from the main drive shaft.

In front of the outlet duct in the annular casing is a fixed plate filling the space between the rotor and the outer member. There is a slot in the centre of this plate through which the blades pass without losing the air seal, as they lie parallel to the direction of rotation at this point.

Between the blades are four fixed spacers, which also pass through the slot, maintaining a constant seal throughout the complete cycle. Once clear of this slot, the blades swivel to act as compression members. Compression then takes place by back-flow.

As back-flow occurs in a stationary enclosed space it does not impose a reverse torque load on the working mechanism. In this the Bicera design differs from the Roots-type blower, where heavy back-flow loads are imposed on the approaching lobe.

Frictional losses in the blower arc low. The rotor runs on ball bearings and the blades are also ball-bearing mounted. The gear train is only lightly loaded, as it runs at half the speed of the rotor, and it is lubricated by an oil bath. To prevent contamination of the air charge by oil, the bearings closest to the air space are a grease-packed neoprenesealed design and act as an effective barrier.

On test a prototype Bicera blower fitted to a 4.73-litre six-cylindered oil engin6 gave a 20 per cent. improvement in engine torque with little increase in the minimum specific fuel consumption. The blower, running at twice engine speed, was operating at up to 5,000 r.p.m. during these tests to give a delivery pressure of 6