PREPARING COMMERCIAL MOTORS FOR EXPORT.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

How Vehicles are Packed at a London Works for Shipment.

IF the reader will imagine a convoy of lorries—heavy six-wheelers 'will not be too large—being driven under their own power' into one entrance of a factory and, later, the same lorries being hauled on trailers away from the factory literally packed in huge wooden boxes, he will have a rough idea of the work performed by the packing department of R. and J. Park, Ltd.

This company's Dominion Works, at Thames Road, Chiswick, London, W.& occupies an area of approximately 3 acres, 60,000 sq. ft. of which space are covered with up-to

date and well-arranged buildings. These buildings, as we have indicated above, are entirely devoted to the packing of heavy motor vehicles, machinery, etc., for shipment to the Colonies and foreign countries. We may say that commercial motors appear to predominate in the flow of produce of various kinds through the factory.

At this juncture it is as well to mention that there is a large bonded warehouse incorporated in the factory for imported vehicles passing through the works.. There is a Customs official in charge. This department, however, is

not our main concern at the moment, so we will return to our description of the packing section of the factory.

On entering the works, the vehicle, which is to be packed, or cased, is driven straight on to a wash, where it receives a thorough cleaning and all the fuel and oil is drawn or drained from the chassis. The machine, now spick and span, is pushed into the packing shop, where about 50 men are busily engaged. Here all the nickel and bright parts of the chassis and body are treated with a special form of compound to protect them from the ill-effects of moisture.

The foreman next takes the plan measurements of the machine, and wood, drawn from the company's £2,000 stock of timber in its own yard on the premises, is cut to the required sizes and pieced together to form a base, strengthened with runners, for the box. Incidentally, 12 circular saws are constantly employed in cutting the timber for these cases.

The wheels are removed from the vehicle, which is placed on the wooden base, the springs and other parts being held by wood blocks. The tyres are

deflated and the wheels are placed under the chassis, these also being secured by wooden blocks. All the delicate fittings are removed and placed inside the body of the vehicle, securely packed and wadded to prevent damage. Other hanging and loose equipment is, wherever possible, clamped down to the base.

The sides and ends for the box are then made, strengthened with battens and fixed into position on the base. When all the packing has been pronounced to be satisfactory by the foreman' the lids for the cases are constructed and fastened down. Incidentally, it may be mentioned that the whole ease is lined with strong, waterproof paper and that ventilation holes are left in the ends and sides.

When complete, the case is moved under a crane and lifted by means of slings on to a trailer, which is standing in the loading bay. The trailer is drawn away by a lorry and thus the commercial motor is carried to the docks on the first part of its journey overseas.

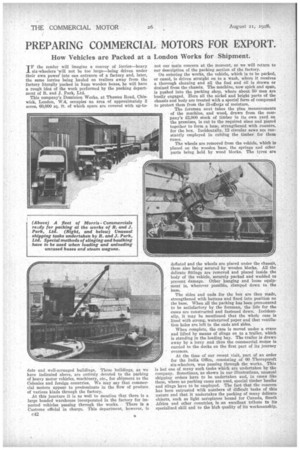

At the time of our recent visit, part of an order for the India Office, consisting of 60 Thornycroft

six-wheelers, was passing through the works.. This is but one of many such tasks which are undertaken by the company. Sometimes, as shown in our illustrations, unusual shipping orders have to be undertaken and, in cases like these, where no packing cases are used, special timber baulks and slings have to be employed. The fact that the concern has been entrusted with numbers of difficult tasks of this nature and that it undertakes the packing of many delicate objects, such as light aeroplanes bound for Canada, South Africa and other countries, is an excellent tribute to its specialized skill and to the high quality of its workmanship.