THE PROBLEM OF SPRING DESIGN.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

A Discussion of Some of the Factors Affecting the Efficiency of Leaf-spring Suspensions.

IT is probably true that in no part of the chassis of a motor vehicle has so little real progress been made as in the case of , springs. Leaf-spring suspensions have been in vogue for thousands of years, and, whilst certain improvements in materials and design have been made, the leaf springs of the Egyptian chariot of 2,000 2.C. bear a marked resemblance to those of a 20th century lorry.

Springing questions are of vital concern to the users of commercial vehicles. To begin with, it is well known that breakages and cost of upkeep are increased if a vehicle be badly sprung, and the takings of a charà.-bancs concern are, of course, directly affected by the qualities of the suspension systems used. Further, there are several kinds of load which may be badly damaged by vibration. There -is also the important fact that the combined effects of heavy loads, increased speeds and bad roads have caused a marked increase in spring breakages.

At first sight it would appear that these matters are the concern of the manufacturer and designer rather than the user of the vehicle. The writer believes that this is a mistaken view, because, although many improvements in design have originated from the works, still more have resulted from the demands of users for improvements. Such demands. can only be usefully made when the user has some knowledge of the principles involved and the difficulties to be inef, so that no excuse should be needed for devoting a little space in these pages to springing problems.

The function of the leaSisprirag is two-fold—it lessens the shock transmitted from the wheel to the chassis, and dissipates part of the energy of the blow in friction between the leaves. This friction effect is very important, and is one of the points to which the superiority of the leaf spring is due. Generally speaking, the effect is that the violent oscillations set up by a bump or pot-hole are rapidly damped out by the friction between the leaves. It is, therefore, rather amusing to see userskof light vans carefully B26 lubricating the leaves and enclosing the springs in gaiters, and then fitting rebound dampers ! Leaf lubrication is only needed to prevent rusting between the, leaves, which would tend to bind them together and make the spring harsh in action. Like all good things, leaf lubrication can be overdone, and an occasional insertion of graphite is all that is really necessary.

Turning to the question of spring design, the first points decided upon are the length and deflectinn. These are settled from considerations of periodicity and resilience, which need not be entered into here. Tho breadth of the plates is the next point ; this mustbe sufficient to provide for adequate strength without undue depth, and must give. sufficient resistance to torsion. Shackle and bracket design, overall dimensions, etc. are other factors which influence the choice of width.

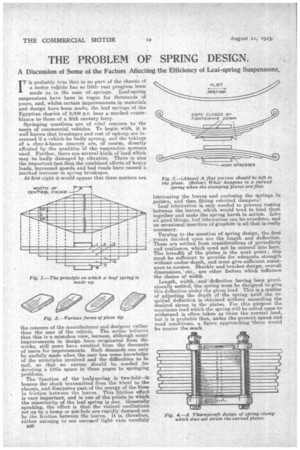

Length, width, and' deflection having been provisionally settled, the spring must be designed to give this deflection under the given load. This is a matter of adjusting the depth of the spring until the required deflection is obtained without exceeding the desired stress in the plates. For this • purpose the maximum load which the spring will be called upon to withstand is often taken as twice the normal load, but it is probable that, under the present speed and road conditions, a figure approaching 'three would be nearer tho mark. In order to design a spring capable of efficient service without undue weight, it is essential that the stresses in every part should be about the same. Now, the bending action of the load is at a maximum at the edges of the central fastening, and is zero at the ends of the spring, so that, if a spring consisted of a single plate, the shape in plan would be trapezoidal, as shown in Fig. 1. The same result is obtained without undue width by employing a number of superimposed plates of graduated lengths, the ends of which should be speared, or of t.ap-ering thickness.

.. The speared ends obtained by cutting up the hypothetical trapezoidal plate are not ideal from a practical view-point, because the loads on the plates are applied at the tips, and a pointed tip would wear rapidly and might tend to dig in. This accounts for the other forms of tip commonly adopted, which are shown in Fig. 2.

• The Central Fixing.

It is important that the central portion of the spring should be considered " dead " and should be firmly clamped to the axle. The majority of springs do not become flat until a considerable load is reached, owing to the camber of the unloaded plates, but when this camber is used the plates should •be rolled so as to leave a flat portion at the centre. If this point be neglected, the deflections of the spring cause the central fitting to work loose, and serious stresses may occur in the plates when the spring is temporarily deflected past the flat portion (Fig. 3).

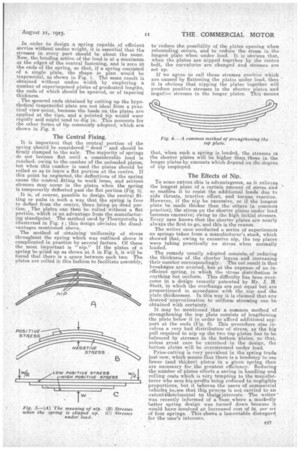

It is, of course, possible to design 'the central fitting or palm in such a way that the spring is free to deflect from the centre, there being no dead portion. The plates can then be rolled without a flat portion, which is an advantage from the manufacturing standpoint. The method used by Thornycrofts is illustrated in Fig. 4; this design obviates the disadvantages mentioned above.

The method of obtaining uniformity of stress throughout the spring which was outlined above is complicated in practice by several factors. Of these the most important is "nip." If the plates of a spring be piled up as shown at A in Fig. 5, it will he found that there is a apace between each two. The plates are rolled in this fashion to facilitate assembly, to reduce the possibility of the plates opening when rebounding occurs, and to reduce the stress in the longest plate when under load. It is obvious that, when the plates are nipped together by the centre bolt, the curvatures are changed and stresses are set up.

If we agree to call those stresses positive which are caused, by flattening the plates under load, then it is obvious that nipping the plates together will produce positive stresses in the shorter plates and negative stresses in the longer plates. This means

that, when such a spring is loaded, the stresses in the shorter plates will be higher than :those in the longer plates by amounts which depend on the degree of nip employed.

The Effects of Nip.

To some extent this is advantageous, as it relieves the longest plate of a certain amount of stress and so enables it to resist the additional loads due to side thrusts, tractive effort., and torque reaction. However, if the nip be excessive, or if the longest plate be made thicker than the others (a common practice), the stress on the shorter plates under load becomes excessive; &wing to the high initial stresses. Every. user knows that the shorter plates are nearly always the first to go, and this is the reason.

The writer once conducted a series of experiments on springs taken from a manufacturer's stock, which showed that, owing to excessive nip, the top plates were taking practically no stresS when normally loaded.

The remedy usually adopted consists, of reducing the thickness of the shorter leaves arra increasing their number correspondingly. The net result is that breaketges are averted, but at the expense of an inefficient spring, in .which the stress distribution is anything but uniform. This difficulty has been overcome in a design recently patented by Mr. J. H. Stott, in which the overhangs are .not equal but are proportioned in accordance with the .nip and the plate thicknesses. In this way it is claimed that any desired-approximation to uniform stressing can be obtained with certainty.

It may be mentioned that a common method of strengthening the top plate consists of lengthening the plate below it in order to afford additional support at the ends (Fig. 6). This procedure also involves a very bad distribution of stress, as the big pull required to nip up the two tap plates has to be balanced by stresses in the bottom plates, so that; unless great care be exercised in the design, the bottom plates will be overstressed under load.

Price-cutting is very prevalent in the 'spring trade just now, which means that there is a tendency to use fewer (and thicker) plates in a given spring than are necessary for the greatest efficiency. Reducing the number of plates effects a saying in handling and rolling costs which is very tempting to the manufacturer who sees his profits being reduced to negligible proportions, but it beheves the users of commercial vehicle toisee that thie process is not carried to an extentltdetrimeetal to th.eiso interests. The writer -was recently informed of a -Vase where a markedly better spring design was turned down because it would have involved an increased cost of 5s. per set of four springs. This .shows a lamentable disregard, for the user's interests.