Words: Ian Griffin / Images: Craig Eccleston

Page 31

Page 32

Page 33

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

ocks away

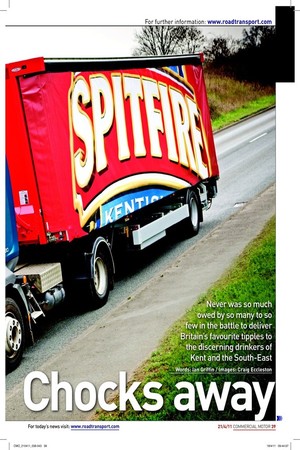

Never was so much owed by so many to so few in the battle to deliver Britain’s favourite tipples to the discerning drinkers of Kent and the South-East

As you nurse a pint of best bitter in your local pub or down a gin and tonic at the bar after a hard day enjoying the cricket, spare a thought for the transport people who did their bit to make sure your drink reached your hands in good time and condition. In particular, the dray crews who deliver the kegs, casks and cases of bottled beer to pubs and clubs, who not only have to cope with today’s stringent parking enforcement and congested roads, but also with having to manoeuvre laden trucks into some very tight spaces to get close enough to make their pub deliveries. It’s something dray crews do every day but, having to reverse a truck down what is basically an alley, with only millimetres to spare either side, is enough to make your average driver yearn for the comparatively wide open spaces of a supermarket DC. Although the architectural quirks are part of its charm, it’s a fact that your typically picturesque, traditional English hostelry was often built in the 16th or 17th centuries when horse and cart would have provided the transport.

Over the past 25 years, and certainly since the Beer Orders of 1989 created more competition between brewers, wholesalers and pub retailers, the drinks industry has developed what has pretty much become a standardised distribution system for getting the beer to the pub on time. In effect, this usually involves the primary distribution of product being carried out using maximum weight artics trunking between breweries’ and producers’ RDCs and their customers’ – such as retailers’ RDCs. Meanwhile, this is supported with secondary distribution duties being handled by smaller trucks and vans. The latter being used especially for bespoke deliveries – sometimes consisting of only a single case of spirits or cask of beer and often to a pub in a remote location in the countryside.

Faversham, Kent-based Shepherd Neame is a typical operator of an urban artic secondary distribution leet that they use to make pub deliveries. The irm claims to be Britain’s oldest brewer, tracing its roots back to at least 1698. Now predominantly owned by the ifth generation of the Neame family, the company brews and retails its own beers under a range of highly successful brands like Spitire and Bishop’s Finger, which are sold both through its 369 pubs across the South East and its customer base of other retailers and public houses. Both Spitire and Bishop’s Finger are currently in the top 10 premium bottled ales league.

Shepherd Neame also brews a range of beers and lagers under licence, including Oranjeboom, Asahi, Kingisher and the Hong Kong Brewery’s Sun Lik. Total product output from Faversham is around 300,000 brewers’ barrels of around 36 gallons each that are shipped every year. Pub deliveries add up to around 2,500 tonnes a month. Deliveries to supermarket customers and wholesalers is growing, and two independent third party hauliers, Young Brothers and Fast Forward Transport at Sittingbourne look after the primary distribution.

According to the interim inancial results announced on the 16 March, Shepherd Neame shipped ‘record beer volumes’ in the six months to 25 December 2010 and retail sales for the nine weeks since the end of last year were up by 11.4%.

CM went along to see how it uses its 15-strong leet of Volvo FL urban artics and ask what beneits they bring to the in-house transport operation. Our guide is transport manager Simon Lathwell-Fisher, who has been with Shepherd Neame for four years. Lathwell-Fisher has worked for some of the biggest names in the drinks industry logistics sector, such as Carlsberg, and explains why he continues to use Volvo as the main vehicle on the secondary distribution leet: “Urban artics were in the leet before I joined Shepherd Neame,” he says. “They have excellent manouverability compared with a rigid. The Volvos have proven to be very reliable and we get really good support from our local dealer, MC Truck and Bus at Maidstone. Downtime is minimal, which is good as it’s such a specialised combination that it wouldn’t be possible to get hold of a replacement if one was off the road.” The Volvo dealer also carries out MoT tests, and Lathwell-Fisher says that he is happy with the irst time pass rate achieved currently. Trailers are all Don-Bur and feature Safe Suzie boom mounts on the front bulkhead, in order to reduce the need for the crew to climb between the tractor and the trailer. The trailer spec is almost identical to the industry standard Don-Bur urban artic trailers used by KNDL among others.

In the interests of reducing fuel costs, Shepherd Neame is looking at introducing a Tear Drop coniguration urban artic trailer next year. Half the leet is already at Euro-5, but, says Lathwell-Fisher, they need to be convinced of the eficiency of the return on investment before switching to alternative fuelled vehicles or hybrid power. Speciication of the Volvos includes a longer cab to allow the two man crew to stow wet weather gear, and a manual six-speed gearbox – the preferred choice of the drivers.

The Shepherd Neame leet of HGVs consists of 19 vehicles with, in addition to the 15 Volvos, 2 Renault rigids, a Mercedes-Benz 7.5-tonner and an Iveco 6.5-tonne van. To paraphrase the Heineken television commercial, the latter vehicles are used to restock the pubs other trucks can’t reach – either due to poor access or the bespoke, ie small, nature of the load. A new Volvo 18-tonne rigid is on order too. The latter is to be based at Crayford to reduce the amount of manual handling at the depot when trans-shipping smaller loads. The FL’s 280hp is an improvement on the previous FL6’s 220hp. “Kent is surprisingly hilly and the FL at 280hp is easy and nice to drive,” says Lathwell-Fisher.

I don’t like cricket...

Shepherd Neame’s Volvo FL urban artics are plated for operation at 25 tonnes GCW and, in addition to making pub deliveries, are pressed into service to provide stocks of drink for wedding venues and even cricket matches. Indeed, the brewer has been a high proile sponsor of both Kent and Essex County Cricket Clubs for many years. A novel innovation at outdoor events is the use of several insulated, chilled trailers to help keep the stock of beer, wine and non-alcoholic beverages in perfect condition for customers in the summer heat.

In addition to the soon to be expanded (to meet increased demand) DC at Faversham, where it has been located for seven years after outgrowing the old brewery site, the company also has an outbase at Crayford to handle London and Essex deliveries. Deliveries are made to many famous landmark London pubs, such as the Freemason’s Arms in Covent Garden and the Jamaica Inn at Moorgate. Deliveries from Crayford can range as far north as Harwich. Deliveries to the west of London from Crayford include those to Berkshire, while Faversham looks after Kent and the South Coast. As the majority of the Volvos are Euro-4 and -5, compliance with the London Low Emission Zone (LEZ) from January 2012 is not an issue. More of a concern, says Lathwell-Fisher, is the management of the Olympic Routes and delivery schedule windows next year. “We’re going to end up delivering to pubs at night and we’re concerned on behalf of residents about the noise that metal kegs make when dropped and rolled into pub cellars. There’s also going to be a £200 penalty ine for making deliveries outside of the midnight to 6am slot. We’re concerned that delivery companies will end up being forced to deliver outside of the schedule because of the sheer volume of companies trying to get into London at the same time on the restricted Olympic routes.” Shepherd Neame is a member of the Brewery Logistics Group and, like other affected hauliers, is waiting for the results of noise tests being carried out in London by local authorities, and subsequent announce ments about the Olympic routes and delivery terms following a meeting in this month.

Each of the Volvo urban artics makes up to 25 deliveries a day and averages 65,000km a year. Fuel currently accounts for around 30% to 35% of costs, explains Lathwell-Fisher. The irm is looking at installing black box telematics on the Volvos to integrate into the Paragon load planning, routeing and scheduling systems, which itself is linked to the SAP logistics system.

Fuel savings is the main driver for this, he says: “We use the services of Petroplus to spot buy and get the most competitive price for the diesel we bunker at Faversham. However, we have also studied how we can improve fuel economy by up to 15% through other means such as tyre pressure monitoring, tracking, wheel alignment and tyre choice.”

Looking at Shepherd Neame’s latest Volvo urban artics, it’s easy to see how the concept has proved such an attractive formula. The small 4x2 tractor unit just looks right with its tapered Don-Bur trailer, and – to use the tried and tested Jeremy Clarkson Top Gear formula: if it looks right, it is right! ■