THE HALL OF FAME 3

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

More of our transport veterans make their case for the all-time drive of the century praising quality, innovation and, some of the time, just being Swedish.

With a Rolls-Royce engine, a Fuller twin-countershaft gearbox and Leyland hub-reduction axles, the Crusader was built for a long, strong life.

Could it happen today? Not a chance. For a start operators have neither the time nor the inclination.And the truck manufacturers would argue, with ample justification, that they offer a spec for every occasion, Back in the early seventies the situation was different. Vertically integrated manufacturers were feeling their way into a parochial British market that was littered with vehicle assemblers who relied on third-party suppliers for most major components.

This left the way open for one operator to exercise its clout in influencing the design of its fleet motor —and out of the subsequent co-operation between Leyland subsidiary Scammell and the stateowned British Road Services was born the haulage version of the Scammell Crusader.

The 4x2 was to be based on the 6x4 version launched in l968.It was to be a light tractor— a 'premium' Scamrnell to operate on intensive trunking at 32 tonnes GCW and designed with an eye to the oft-mooted increase to 38 tonnes that eventually surfaced in 1983... long after the Crusader had passed into history.

Outwardly the BRS-spec Crusader was not hard to spot. It was a long-wheelbase 4x2 tractor that sported a distinctive slab-fronted Motor Panels day cab that had something of a North American look to it, a view reinforced by a massive Kysor radiator shutter/grille.

Then, as now, operators lusted after reliability and longevity. Not by accident, therefore, was the spec centred around three major components that had already proved themselves:a Rolls Royce Eagle engine: Fuller twin-countershaft gearbox; and Leyland hub-reduction axle.

Perhaps it was too early for the design to be influenced by the Scandinavian invaders; perhaps it just wasn't needed. In any case a fixed cab, albeit with full suspension and a high floor, was chosen in preference to the tilting variety.

When it came to routine servicing that huge vertically hinged radiator/shutter assembly swung aside to give easy access to the front of the engine for engine oil checks and replenishment.Further access to the capacious engine compartment was via a hatch in the cab floor. Commercial Motor, in the guise of the latest recruit to its technical team—me — had two opportunities to run the rule over the new vehicle on our 729-mile operational trial.These tests highlighted the suitability of the spec for the purpose intended: namely intensive trunking. Despite being hard pushed to handle the severe sections of roads such as the A68, the Crusader still managed to return 6.5mpg which was "among the best at this gross weight over the route".

Not since has an operator had such an obvious influence in the design of his fleet motor.The Crusader was the last of a breed — it's my truck of the century.

TrevorLongcroft joined the technical team at CM in 1971, leaving in 1976 as assistant technical editor He then followed a career in public relations with Leyland and subsequently, Volvo Truck and Rus before launching as an indepetmlent public relations consultant in 1999.

Scania R Series

Isit really the truck lovers' truck with enough power, torque and comfort to make an enthusiast tremble? Andy Salter would have you believe it.

It's all very well looking back through rosetinted specs at the commercials of bygone times, but the current products are more efficient,more modern arid altogether more civilised machines.And clearly the Scania R Series, as the reigning International Truck of the Year, has to be the daddy of them all.

Ever since the Swedes arrived over here in the late 1960s the products produced by Scania and fellow Swede Volvo have had a massive impact on the landscape of the UK truck industry.The focus on driver comfort alone was enough to see off the draughty, poorly designed machines from many UK manufacturers.

It's no accident that Scania's products have built such an enviable driver following, with its products achieving"King of the Road" status inmost sectors in which it competes.

The latest incarnation of the Scania story is the R Series;itself a development of the successful 4 Series. In the current climate of driver shortages this truck takes in-cab comfort and driveability to new levels and for that reason alone deserves to take its place at the head of any top-truck league table. Under the cab sits a throbbing 15-litre V8 engine that makes light of the most gruelling jobs.

OK.so it hasn't joined the over 600hp bracketjust yet, but that's only because Scania transmissions can't yet handle the torque from these top-power machines. New gearboxes due soon will address that issue — then watch this baby fly.

The Scania's strength isn't only down to its engine line-up, impressive as it is. Braking, axles and suspension combine to give the Scania unrivalled handling and sheer driveability more usually associated with passenger cars than 44-tonners.What's more it's all developed in-house by ones the world's very few profitable truck makers. Surely the greatest commercial of all time should be built by a manufacturer that's still thriving today. Move inside and the positives keep flowing. Comfort is now a definite plus with improved leg and knee room, while the rest of the cab has been arranged to suit the driver of 2005 and beyond.

Excellent internal headroom, cavernous lockers and exceptional build quality, combined with a sound system to die for and a bunk which puts your average Travelodge to shame and you've got some idea of the treat that awaits those lucky enough to get to drive the greatest commercial vehicle of all time.

To paraphrase a former editor of Commercial Motor,"Anyone who doesn't enjoy driving Scanias, doesn't enjoy driving." Enough said!

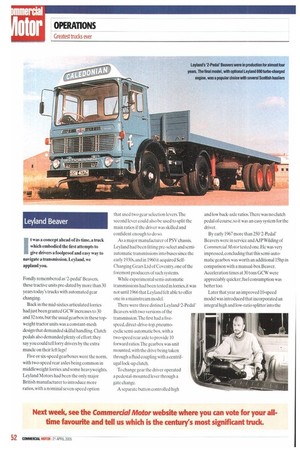

Leyland Beaver

It was a concept ahead of its time, a truck which embodied the first attempts to give drivers a foolproof and easy way to nal igate a transmission. Leyland, we applaud you.

Fondly remembered as `2-pedal' Beavers. these tractive units pre-dated by more than 30 years today's trucks with automated gear changing.

Back in the mid-sixties articulated lorries hadjust been granted GCVV increases to 30 and 32 tons, but the usual gearbox in these topweight tractor units was a constant-mesh design that demanded skilful handling. Clutch pedals also demanded plenty of effort; they say you could tell lorry drivers by the extra muscle on their left legs!

Five or six-speed gearboxes were the norm, with two-speed rear axles being common in middleweight lorries and some heavyweights. Leyland Motors had been the only major British manufacturer to introduce more ratios, with a nominal seven-speed option that used two gear selection levers.The second lever could also be used to split the main ratios if the driver was skilled and confident enough to do so.

As a major manufacturer of PSV chassis, Leyland had been fitting pre-select and semiautomatic transmissions into buses since the early 1930s, and in 1960 it acquired SelfChanging Gears Ltd of Coventry. one of the foremost producers of such systems.

While experimental semi-automatic transmissions had been tested in lorries, it was not until 1966 that Leyland felt able to offer one in a mainstream model.

There were three distinct Leyland '2-Pedal' Beavers with two versions of the transmission.The first had a fivespeed, direct-drive-top, pneumocyclic semi-automatic box, with a two-speed rear axle to provide 10 forward ratios.The gearbox was unit mounted, with the drive being taken through a fluid coupling with a centrifugal lock-up clutch.

To change gear the driver operated a pedestal-mounted lever through a gate change.

A separate button controlled high and low back-axle ratios.There was no clutch pedal of course, so it was an easy system for the driver.

By early 1967 more than 250 '2-Pedal' Beavers were in service and AJP Wilding of Commercial Motor tested one. He was very impressed, concluding that this semi-automatic gearbox was worth an additional 15hp in comparison with a manual-box Beaver. Acceleration times at 30 tons GCW were appreciably quicker; fuel consumption was better too.

Later that year an improved 10-speed model was introduced that incorporated an integral high and low-ratio splitter into the five-speed gearbox. A hub-reduction unit replaced the two-speed axle.The splitter was a step-up, or overdrive, gear that gave a top speed of 60mph with the standard back-axle ratio; it was air operated by a switch in the gear lever.

The most exciting `2-Pedal' version of what was already an advanced lorry for its time appeared in late 1968 with a 240hp turbodiesel a powerful engine for that era.

Unfortunately, like other Leyland Group models of the late sixties and early seventies, the '2-Pedal' Beaver had lots of potential but was destined to fail. It was an advanced lorry for its time; there was nothing comparable from competing manufacturers either at home or overseas. So why did it fail? Lack of development was one reason.While semiautomatic transmissions were proven in PSVs, the demands placed on them in a 30/32-ton lorry were completely different.

Back in the late sixties lubricant technology was not as advanced as it is today.After a flatout thrash along a motorway the oil in a pneumo-cyclic gearbox would often be boiling, which ruined the seals and glands in the fluid flywheelit also resulted in premature geartrain wearThe more powerful turbocharged engine exacerbated these faults, and that unit was also somewhat unreliable and prone to cylinder head gasket failures .Then there was the temptation for drivers to change gear by rushing the lever straight through the gate without pausing in neutral.

This contributed to failures, but if used like a conventional box and held in neutral for a moment or two.it was a reliable transmission and a delight to use.

A few other Leylands got this gearbox; notably the Octopus. Associate group companies such as AEC and Scammell also fitted pneumo-cyclic units into some of their heavyweights, but none was successful in the long run.

Quite simply it was a transmission concept 25 years ahead of its time, but let's applaud Leyland for its foresight with its attempts to provide a simple. foolproof, gear changing method for drivers that was well in advance of the competition.

Volvo F88

7 0 K trucks should hang their beads in shame. If you wanted greatness, look to the Swedes...

Call me unpatriotic but the F88 is the vehicle that showed British manufacturers how to build a working truck. At a time when AEC, Bedford and Leyland thought it perfectly acceptable to flog British hauliers substandard, underpowered sheds on wheels, the crafty Swedes gave us a commercial vehicle that could be driven to Tehran and back without drinking a cupful of oil, while Bedford drivers back in Blighty poured in another half gallon during their dinner breaks.

The F88 may have been the poor relation of the left-hand-drive 330hp F89 driven by our Continental cousins, but its contemporaries on the UK market paled in comparison.

With its distinctive looks (its cab originated with the 1964Titan TIPTOP) the F88 was engineered to a standard years ahead of its UK rivals, incorporating a host of new features in a single vehicle.

Volvo's driveline was remarkable for the time:a 260hp straight-six turbo-diesel coupled to a synchromesh range-change gearbox,with the option of a splitter from 1969. Servicing was simplified by the tilt cab and drivers worked in added security as a crash-tested metal shell surrounded them.

Factor in sprung seats, a heater that worked, doors with decent seals and a cab that didn't let in water when it rained—no wonder, then, that the F88 was soon the vehicle of choice for commercial cognoscenti.This soon became the drivers' dream — it was synonymous with long-haul transport.

It soon became a mainstay of our haulage operation. Almost every major transport fleet had an F88 among its ranks at some point during the next decade, and once they tried the Swedish marque many hauliers were loathe to return to home-brewed products,When the Fl 0 arrived in the Queen's Jubilee year it built on those solid foundations.

Of course the F88 wasn't without its faults. With 240hp on tap as standard the 9.6-litre TD100A engine was more powerful than most of its British built peers (who were duly grateful for the 180 version of the Gardner power plant under their fixed cabs), and it proved exceptionally reliable.

Only the UK-spec 290hp version gave any real problems, though this seldom occurred on hard working examples.The cabs were susceptible to a bit of tin worm but several 30-year-old examples are still earning their keep in the UK.

Longevity and durability were the hallmarks of the F88, at a time when virtually every other heavy commercial marque was plagued by reliability issues. But that wasn't the whole story.

Under the keen leadership of importer Jim McKelvie the truck was supported with the kind of aftersales service that put the British manufacturers to sharne.The rest, as they say, is history.