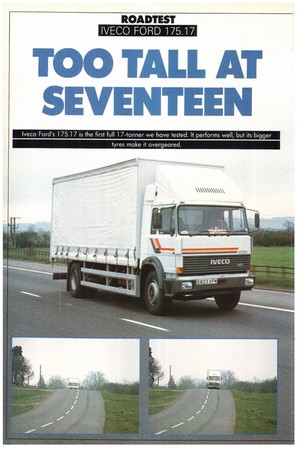

TOO TALL AT SEVENTEEN

Page 60

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

Iveco Ford's 175.17 is the first full 17-tonner we have tested. It performs well, but its bigger tyres make it overgeared.

• At the beginning of this month the maximum weight for two-axled rigid vehicles rose to 17 tonnes. At first glance this appears to offer an immediate payload benefit of 740kg for those vehicles able to take advantage of the change in regulations with a design weight of 17 tonnes and above. Vehicles plated at the lower weight will have to be presented at a test station, suitably modified to comply with the new legislation.

For many models the modifications that will allow them to operate at the new limit mostly relate to changes in their tyre and wheel equipment.

Our first test at 17 tonnes is of the Iveco Ford 175.17, fitted with 12R tyres and wheels in place of the original 11R equipment. Larger, heavier tyres and wheels reduce the payload advantage by about 91kg — 13kg for each of the seven wheels including the spare.

Changing the tyre size inevitably alters the overall gearing; the increased rolling circumference raises the geared speed by almost 3% to 110km/h (68.5mph). As no compensation has been made in the final drive ratio, performance at the lower end had to suffer, and at the MIRA test track we were unable to pull away up any test hill steeper than 16.7% (1-in-6). While this meets legal requirements and may prove adequate for most occastions, those operating in very hilly areas will be pleased to hear that Iveco supplies the vehicle with a set of wheel chocks.

The Iveco 8065.25 six-cylinder turbocharged engine is a high revving unit, reaching maximum power of 130kW (177hp) at 2,700rpm. Maximum torque of 560Nm (413Ibft) is achieved at 1,600rpm, but drops off sharply above 1,900rpm.

While 7.3kW/tonne (10hp/ton)-plus may be considered handsome at 38 tonnes, even before the weight increase this level of power-to-weight ratio was exceeded by many of the current maximum-weight two-axled rigids.

The profile of the 5.8-litre engine's power curve shows that output declines rapidly as engine speed is reduced, so that by 1,900rpm it only develops 108kW (145hp). The result of this is insufficient torque to allow the engine to lug down on anything but flat going. Despite the high power-to-weight ratio, this is not a lazy engine but it must be driven hard to achieve even average journey times.

With the optional 12-speed ZFS 6.36 synchromesh splitter gearbox there is a gear for every eventuality, but to maintain progress the rev counter needs to be kept above 2,000rprn — still in the green at up to 2,300rpm.

In top gear 2,350rpm gives a road lo• speed of 96krn/h while 2,000tpm gives 801cm/h and 1,575rpm 64km/h. The stubby gear lever with a short throw and easy gate, naturally biased to third and fourth, made full gear changes easy and sure. Engaging the split ratios, preselected using a switch on the lever and applied simply by dipping the clutch pedal, is even quicker.

Throttle pedal effort is light, but the door-mounted stowage pouch could be an obstruction to free leg movement.

Over our amended Welsh route, now starting at Chievely services at junction 13 on the M4, the 175.17 returned a creditable 25.1 lit/100Icm (11.23mpg) at an average speed of 62.1km/h. (38.57mph). The additional 24.81cm is made up entirely of motorway running, so average speeds can be expected to be slightly faster than those of vehicles tested at 16.26 tonnes.

Without direct comparisons at 17 tonnes, productivity comparisons with earlier maximum-weight rigids, using the "payload x speed ÷ fuel consumption" equation are valid.

From the chart it can be seen that, even with a relatively low power output, the 175.17 compares well with models previously tested but a design weight of just 17 tonnes limits the front axle to 6.5 tonnes, allowing no latitude in load distribution for a fully-laden vehicle.

• BRAKING

Under normal light applications the Stopmaster wedge brakes respond readily, but on the track the Motometer brake records indicated a slow build-up, taking a full second to achieve peak deceleration under maximum pedal effort.

This is reflected in the overall decelerations and stopping distances. From 50 and 64Iun/h the load-sensing valve failed to prevent the drive axle locking up towards the end of the stops. The front axle could not be made to lock, and from 641cm/h the vehicle ended its braking test a few degrees out of line. Exhaust brake efficiency depends greatly on the gear ratio, working best at high engine revs.

• CAB COMFORT

Acceleration, impaired by the large tyres, is poor — much slower than models we have tested at 16.26 tonnes. The tyres also accentuate the poor ride.

Back complaints continue to be one of the major causes of absenteeism in the UK, yet many drivers supplied with suspension seats still prefer to lock them out. We tried both settings and found a marked improvement in comfort with the seats suspension operational, a fact borne out by ride measurements made for a range of vehicles in our recent cab test.

While long parabolic springs on the front and rear axles give a softer ride than their multi-leaf equivalents, on their own they fall short of providing the level of comfort every driver should be entitled to. Chassis roll, however, is effectively restrained by anti-roll bars on both axles.

At all speeds noise levels are acceptable, but there is room for further improvement in both the intake and exhaust to make the cab even quieter.

The cab is mounted high on the chassis for an urban delivery vehicle, so three steps must be climbed to gain access. Provided the right foot is placed on the lowest rung this can be achieved using the grab handles — one at the end of the facia and the other at the rear of the door opening — without pulling up on the steering wheel. The gear lever, mounted on top of a low engine cowl, obstructs free cross-cab movement.

The cab's interior is surprisingly spacious, with enough room behind the seats for a suitcase, and they are a fasciamounted glove box and door pouches.

Below the header rail the front screen is quite shallow. While forward visibility is not impaired, upward visibility for road signs and traffic lights is.

Instrumentation covers all of the necessary functions but might be improved if the tachograph were to be changed over with the tachometer. Daily oil checks are made behind the front grille, which folds downwards. Air flow equipment, filling the gap between the cab and the Tautliner body, prevents ready access to the coolant header tank. The cab must be tilted if topping-up is needed, and before tilting, the tow pin should first be removed to avoid fouling the front grille.

Despite the mandatory side-guard rails and body-side overhang the filler neck to the 200-litre fuel tank remains within easy reach. Access to the batteries is simplified by a hinged gate section at the front of the side rail.

• SUMMARY

The full implications of simply uprating tyre equipment may not have been fully realised and further specification changes may yet materialise.

Not only does the larger wheel circumference increase tyre life and increase platform height, it also raises the overall gearing of the vehicle.

With a relatively low power output at the new weight limit the 175.17 needs to be driven hard just to keep up with other traffic, and to compensate for the poor acceleration and sharp drop-off in power as the engine revs fall. Nonetheless, overall journey times are about average and overall productivity is high — more than compensating for the small increase in fuel used to move the extra payload.

The smooth gearbox operation makes less of the constant gearchanging needed to keep the engine churning in the upper limits of the green sector. More power and lower gearing, however, would improve hill restart performance and reduce gearchanging frequency.

Unlike the Cargo, the 175.17 has a chassis price which increases with length.

The basic price for the 5.55m wheelbase model is 226,190 but the change in tyre equipment brings this up to 226,554 and the splitter box carries a 2520 premium. Even so it is competitively priced costing less than the Scania P93, but more than the ERF E6 4x2.

Eby Bill Brock