road and workshop

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

by Handyman

Auto-electrics for the mechanic (16)

ALTHOUGH I mentioned the alternator in an earlier article it will be as well to outline how this generator differs from the dc dynamo. This machine does not employ a commutator and it is self-regulating. The commutator is not required to provide de from the armature, so that the field coils can now be built into the revolving part, ie the rotor.

In the first instance the output is of course alternating current, which is converted to the required direct current by built-in static rectifiers. These require practically no attention compared with the dc commutator they replace. Because the maximum current output is self-regulated, the only external requirement is a voltage regulator.

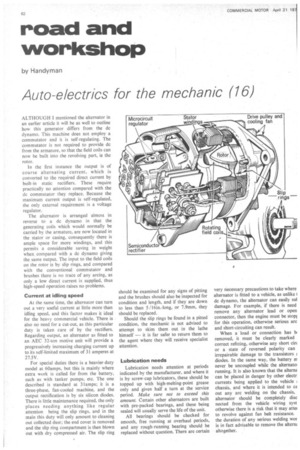

The alternator is arranged almost in reverse to a de dynamo in that the generating coils which would normally be carried by the armature, are now located in the stator or casing, consequently there is ample space for more windings, and this permits a considerable saving in weight when compared with a dc dynamo giving the same output. The input to the field coils on the rotor is by slip rings, and compared with the conventional commutator and brushes there is no trace of any arcing, as only a low direct current is supplied, thus high-speed operation raises no problems.

Current at idling speed At the same time, the alternator can turn Out a very useful current at little more than idling speed, and this factor makes it ideal for the heavy commercial vehicle. There is also no need for a cut-out, as this particular duty is taken care of by the rectifiers. Regarding output, an alternator as fitted to an AEC 32-ton motive unit will provide a progressively increasing charging current up to its self-limited maximum of 31 amperes at 27.5V.

For special duties there is a heavier-duty model at 60amps, but this is mainly where extra work is called for from the battery, such as with tanker pumps, etc. The one described is standard at 3 lamps; it is a three-phase, fan-cooled machine, and the output rectification is by six silicon diodes. There is little maintenance required, the only places needing anything like regular attention being the slip rings, and in the main this duty will only amount to cleaning out collected dust; the end cover is removed and the slip ring compartment is then blown out with dry compressed air. The slip ring should be examined for any signs of pitting and the brushes should also be inspected for condition and length, and if they are down to less than 5 /16in.-long, or 7.9mm, they should be replaced.

Should the slip rings be found in a pitted condition, the mechanic is not advised to attempt to skim them out in the lathe himself — it is far safer to return them to the agent where they will receive specialist attention.

Lubrication needs

Lubrication needs attention at periods indicated by the manufacturer, and where it is by screw-cap lubricators, these should be topped up with high-melting-point grease only and given half a turn at the service period. Make sure not to exceed this amount. Certain other alternators are built with pre-packed bearings, and these being sealed will usually serve the life of the unit.

All bearings should be checked for smooth, free running at overhaul periods, and any rough-running bearing should be replaced without question. There are certain very necessary precautions to take where alternator is fitted to a vehicle, as unlike 1 dc dynamo, the alternator can easily sill damage. For example, if there is need remove any alternator lead or open connector, then the engine must be stop! for this operation, otherwise serious arc and short-circuiting can result.

When a load or connection has hi removed, it must be clearly marked correct refitting, otherwise any short cirt or a state of reversed polarity can irrepairable damage to the transistors diodes. In the same way, the battery in never be uncoupled while the alternatoi running. It is also known that the alterna can be placed in danger by other electr currents being applied to the vehicle ; chassis, and where it is intended to ca out any arc welding on the chassis, alternator should be completely disc nected from the vehicle wiring syst otherwise there is a risk that it may attei to revolve against fan belt resistance. the duration of any serious welding wor is in fact advisable to remove the ahem altogether.