An Outline of

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

ROOF CONSTRUCTION

This Week our Bodybuilding Expert Deals with the Subject of Heads for Passenger Vehicles and Makes a Thorough Survey of the Subject How the Various Components of a Roof for a Coach or Bus are Assembled, Mention Also Being Made of the Use of Sliding Heads

THE roof of the coach or bus is a means for protecting passengers from the weather, and it must be waterproof, but, at the same time, it is often designed so as to form an important part of the ventilating scheme. The roof may support no weight, apart from its • own framework, panelling and fittings, or it may be used for carrying luggage, whilst, as the intermediate roof of a double-decker, it is the ceiling of the lower saloon and the floor of the upper one.

The roof is given a certain shape for both practical and artistic reasons, and its construction may vary according to whether wood or metal be used and to the method of assembly.

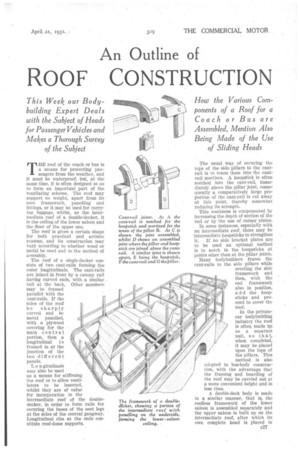

The roof of a single decker consists of two cant-rails forming the outer long-itudinals. The cant-rails are joined in front by a canopy rail having curved ends, with a similar rail at the back. Other members may be framed

parallel with the cant-rails. If the sides of the roof be sharply curved and be metal panelled, with a plywood covering for the main central portion, then a longitudinal i s framed in at the junction of the two different panels.

L o n gitudinals may also be used as a means for stiffening the roof or to allow ventilators to be inserted, whilst they are of value for incorporation in the intermediate roof of the doubledecker, in order to form rails for securing the bases of the seat legs at the sides of the central gangway. Longitudinal ribs at the ends constitute roof-dome supports. The usual way of securing the tops of the side pillars to the cantrail is to tenon them into the cantrail mortises. A hoopstick is often notched into the cant-rail, immediately above the pillar joint, consequently a comparatively large proportion of the cant-rail is cut away at this point, thereby somewhat reducing its strength.

This weakness is compensated by increasing the depth of section of the rail or by the use of corner plates. In sotne instances, especially with an intermediate roof, there may be 'intermediate hoopsticks to strengthen it. If no side bracket plates are to be used an optional method is to notch in the hoopsticks at points other than at the pillar joints. Many bodybuilders frame the cant-rails to the side pillars while erecting the side framework and then, with the end framework also in position, a d d the hoopsticks and proceed to cover the roof.

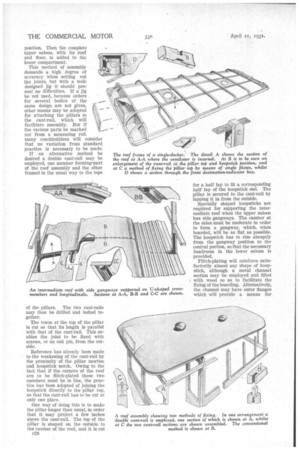

In the privatecar bodybuilding industry the roof is often made up as a separate unit, so that, when completed, it may be placed upon the tops of the pillars. This method is also adopted in bus-body construction, with the advantage that the framing and boarding of the roof may be carried out at a more convenient height and in less time.

A double-deck body is made in a similar manner, that is, the roofless framework of the lower saloon is assembled separately and the upper saloon is built up on the intermediate roof, after which its own complete head is placed in position. Then the complete upper saloon, with its roof and floor, is added to the lower compartment.

This method of assembly demands a high degree of accuracy when setting out the joints, but with a welldesigned jig it should present no difficulties. If a jig be not used, because orders for several bodies of the same design are not given, other means may be adopted for attaching the pillars to the cant-rail, which will facilitate assembly. But if the various parts be marked out from a measuring rod, many coachbuilders will consider that no variation from standard practice is necessary to be made.

If an alternative method be desired a double cant-rail may be employed, one member forming 'part of the roof assembly and the other framed in the usual way to the tops of the pillars. The two cant-rails may then be drilled and bolted together.

The tenon at the top of the pillar is cut so that its length is parallel with that of the cant-rail. This enables the joint to be fixed with screws, or an oak pin, from the outside.

Reference has already been made to the weakening of the cant-rail by the proximity of the pillar mortise and hoopstick notch. Owing to the fact that if the corners of the roof are to be flitch-plated these two members must be in line, the practice has been adopted of joining the hoopstick directly to the pillar top, so that the cant-rail has to be cut at only one place.

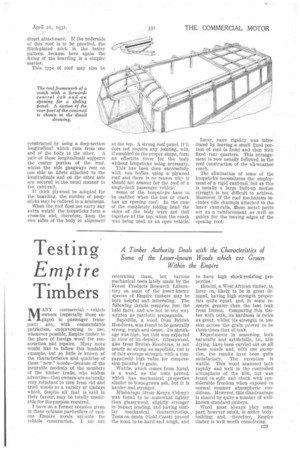

One way of doing this is to make the pillar longer than usual, in order that it may project a few inches above the cant-rail. The top of the pillar is shaped on the outside to the camber of the roof, and it is cut 028 for a half lap to fit a corresponding half lap of the hoopstick end. The pillar is secured to the cant-rail by lapping it in from the outside.

Specially shaped hoopsticks are required for supporting the intermediate roof when the upper saloon has side gangways. The camber at the sides must be moderate in order to form a gangway, which, when boarded, will be as fiat as possible. The hoopstick has to rise abruptly from the gangway position to the central portion, SQ that the necessary headroom in the lower saloon is provided.

Flitch-plating will reinforce satisfactorily almost any shape of hoopstick, although a metal channel section may be employed and filled ; with wood so as to facilitate the fixing of the boarding. Alternatively, the channel may have outer flanges which will provide a means for direct attachment. If the underside of this roof is to be panelled, the flitch-plated stick is the better pattern, because here again the fixing of the boarding is a simpler matter.

This type of roof may also be

constructed by -Using a deep-section longitudinal which runs from one end of the body to the other. A pair of these longitudinals supports the centre portion of the 'roof, whilst the side gangways rest on one side on fillets attached to the longitudinals and on the other side are secured in the usual manner to the cant-rail.

If thick plywood be adopted for the boarding, the number of hoopsticks may be reduced to a minimum.

When the roof does not carry any extra weight the hoopsticks form a cross-tie and, therefore, keep the two sides of the body in alignment at the top. A strong roof panel, if it does not require any jointing, will, if moulded to the proper shape, form an effective cover for the body without hoopstieks being necessary.

This has been done successfully with van bodies using a plywood roof anti there is no reason why it should not answer for the roof of a single-deck passenger Vehicle.

Some of. the hoopsticks have to be omitted when the bus or coach has an opening roof. In the case of the completely folding head the sides of the body were not tied together at the top, when the coach was being used as an open vehicle. Later, more rigidity was introduced by leaving a small fixed portion of roof in front and then with fixed rear quarters. This arrangement is now usually followed in the roof construction of the all-weather. coach.

The elimination of some of the hoopsticks necessitates the employment of a rigid cant-rail, but as this is usually a large built-up section strength is not difficult to achieve. :)Ioreover, if the roof mechanism includes side channels attached to the inner cant-rails, these metal parts act as a reinforcement as well as guides for the moving edges of the opening roof.