WHAT MIGHT

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

HAVE BEEN...

In the second of our Milestones series on classic trucks, Pat Kennett looks at the last ditch efforts by Leyland and AEC before nationalisation.

• There was a time when it was generally agreed that the finest trucks on the market — export arena as well as in Britain — came from one of two places.

One was Southall, on London's western boundary, where the London General Omnibus Co's Associated Equipment Company was based. That later became AEC, whose products from the 1930s through to the 1960s — not forgetting wartime Matadors, Marshals and Militants — were acclaimed worldwide.

The other place was the tiny market and manufacturing town of Leyland in Lancashire, home from the turn of the century for Leyland Motors, formerly the Lancashire Steam Motor Co. The superb Leyland trucks and buses particularly in the 1930s to 1950s, were legendary and, like AEC, world renowned.

The two makes came together in 1962 in one of a whole series of mergers which were industrially fashionable at the time. Leyland already owned Albion, Scammell and Standard Triumph and later the group acquired British Motor Holdings which principally comprised Jaguar, Guy, Daimler, Austin and Morris cars, and the BMC truck group, Rover including Land Rover, and a string of component producers. How all that worked or didn't as the case may be — is a fascinating story of missed opportunities, mechanical disasters and management error, but it isn't part of this particular story. The objective of the merger of these already large groups was to form the world's largest and strongest motor manufacturing business. That might have worked had not motor cars excessively occupied the attentions, not to mention the funds, of senior management. Nevertheless, in the early 1970s the group was a major CV producer, turning out more than 180,000 units annually for a time, in all weight categories from 5cwt vans to heavy trucks and buses. Truck activity remained profitable until 1975, but all the proceeds were siphoned off to the loss-making car divisions, and only paltry sums were retained for truck development.

It was during this period that the last efforts at producing "world beater" trucks took place, before the whole group was taken over by the National Enterprise Board, and in effect nationalised, in 1976. Although the resulting products emerged with AEC and Leyland badges respectively, the bulk of development — such as it was — took place at Southall under AEC control. The fact that many years after the merger there were still quite distinct AEC and Leyland product development philosophies says a lot about the ultimate failure of the group.

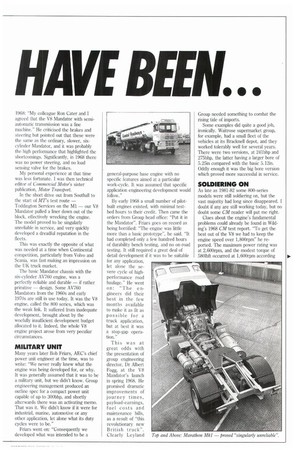

In spring 1968 AEC announced that it had developed "a high output, high performance truck for the 1970s". CM's then technical editor AJP "Tony" Wilding wrote of the V8 Mandator on 31 May

."

1968: "My colleague Ron Cater and I agreed that the V8 Mandator with semiautomatic transmission was a fine machine." He criticised the brakes and steering but pointed out that these were the same as the ordinary, slower, sixcylinder Mandator, and it was probably the high performance that highlighted the shortcomings. Significantly, in 1968 there was no power steering, and no load sensing valve for the brakes.

My personal experience at that time was less fortunate. I was then technical editor of Commercial Motor's sister publication, Motor Transport.

In the short drive out from Southall to the start of Mrs test route — Toddington Services on the M1 — our V8 Mandator pulled a liner down out of the block, effectively wrecking the engine. The model proved to be singularly unreliable in service, and very quickly developed a dreadful reputation in the fleets.

This was exactly the opposite of what was needed at a time when Continental competition, particularly from Volvo and Scania, was fast making an impression on the UK truck market.

The basic Mandator chassis with the six-cylinder AV760 engine, was a perfectly reliable and durable — if rather primitive — design. Some AV760 Mandators from the 1960s and early 1970s are still in use today. It was the V8 engine, called the 800 series, which was the weak link. It suffered from inadequate development, brought about by the woefully insufficient development budget allocated to it. Indeed, the whole V8 engine project arose from very peculiar circumstances.

MILITARY UNIT

Many years later Bob Friars, AEC's chief power unit engineer at the time, was to write: "We never really knew what the engine was being developed for, or why. It was generally assumed that it was to be a military unit, but we didn't know. Group engineering management produced an outline spec for a compact power unit capable of up to 300bhp, and shortly afterwards there was an activating memo. That was it. We didn't know if it were for industrial, marine, automotive or any other application, let alone what its duty cycles were to be."

Friars went on; "Consequently we developed what was intended to be a general-purpose base engine with no specific features aimed at a particular work-cycle. It was assumed that specific application engineering development would follow."

By early 1968 a small number of pilotbuilt engines existed, with minimal testbed hours to their credit. Then came the orders from Group head office: "Put it in the Mandator". Friars goes on record as being horrified: "The engine was tittle more than a basic prototype", he said. "It had completed only a few hundred hours of durability bench testing, and no on-road testing. It still required a great deal of detail development if it was to be suitable for any application, let alone the severe cycle of highperformance road haulage." He went on: "The engineers did their best in the few months available to make it as fit as possible for a truck application, but at best it was a stop-gap operation."

This was at great odds with the presentation of group engineering director, Dr Albert Fogg, at the V8 Mandator's launch in spring 1968. He promised dramatic improvements of journey times, payload-earnings, fuel costs and maintenance bills, as a result of "this revolutionary new British truck". Clearly Leyland Group needed something to combat the rising tide of imports.

Some examples did quite a good job, Waitrose supermarket group, for example, had a small fleet of the vehicles at its Bracknell depot, and they worked tolerably well for several years. There were two versions, at 241bhp and 275bhp, the latter having a larger bore of 5.25in compared with the basic 5.12in. Oddly enough it was the big bore version which proved more successful in service.

SOLDIERING ON

As late as 1981-82 some 800-series models were still soldiering on, but the vast majority had long since disappeared. I doubt if any are still working today, but no doubt some CM reader will put me right.

Clues about the engine's fundamental problems could already be found in Wilding's 1968 CM test report. "To get the best out of the V8 we had to keep the engine speed over 1,800rpm" he reported. The maximum power rating was at 2,600rpm, and the modest torque of 5801bft occurred at 1.600rpm according

to the work leaflets, although Wilding reported it as 1,400rpm. The detail doesn't really matter. It was a poor-torque engine even by the standards of the day, and it needed lots of revs to keep a 32-tonner going at a decent rate. A 2,600rpm power peak was very high for a 12-litre engine, even in those days, and proved altogether too much for the woefully underdeveloped 800.

There is little argument that the 800 series engine was the most miserable failure in the history of the group's vehicular activity. One wonders who was the marketing whizz-kid who dubbed the Rolls-Royce truck engine developed for Leyland in 1984, the 800 series. He had probably never heard of its antecedent, but truck men have long memories.

SKI RESORT

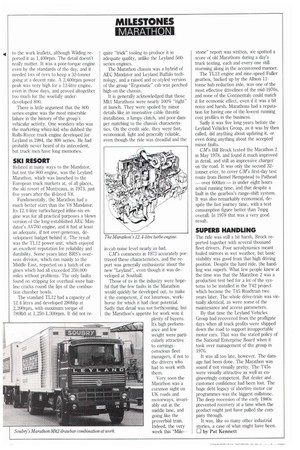

Related in many ways to the Mandator, but not the 800 engine, was the Leyland Marathon, which was launched to the European truck markets at, of all places, the ski resort of Montreaux, in 1973, just five years after the ill-fated V8.

Fundamentally, the Marathon had a much better start than the V8 Mandator. Its 12.4-litre turbocharged inline-six engine was for all practical purposes a blown version of the long-established AEC Mandator's AV760 engine, and it had at least an adequate, if not over-generous, development budget behind it. The result was the nu power unit, which enjoyed an excellent reputation for reliability and durability. Some years later BRS's overseas division, which ran mainly to the Middle East, reported on a batch-of engines which had all exceeded 350,000 miles without problems. The only faults found on stripping for overhaul were hairline cracks round the lips of the combustion chamber bowls.

The standard TL12 had a capacity of 12.4 litres and developed 280bhp at 2,200rpm, with maximum torque of 780lbft at 1,250-1,300rpm. It did not re

quire "trick" tooling to produce it in adequate quality, unlike the Leyland 500series engines.

The Marathon chassis was a hybrid of AEC Mandator and Leyland Buffalo technology, and a raised and re-styled version of the group "Ergomatic" cab was perched high on the chassis.

It is generally acknowledged that those Mk 1 Marathons were nearly 100%. "right" at launch. They were spoiled by minor details like an insensitive cable throttle installation, a lumpy clutch, and poor damper matching to the chassis characteristics. On the credit side, they were fast, economical, light and generally reliable, even though the ride was dreadful and the in-cab noise level nearly as bad.

CM's comments in 1973 accurately portrayed these characteristics, and the report was generally enthusiastic about the new "Leyland", even though it was developed at Southall.

Those of us in the industry were hopeful that the few faults in the Marathon would quickly be developed out, to make it the competent, if not luxurious, workhorse for which it had clear potential. Sadly that detail was not forthcoming, but the Marathon's appetite for work won it plenty of buyers. Its high performance and low weight were particularly attractive to earningsconscious fleet managers, if not to the drivers who had to work with them.

Very soon the Marathon was a common sight on UK roads and motorways. invariably out in the middle lane, and going like the proverbial train. Indeed, the very week this "Mile• stone" report was written, we spotted a score of old Marathons during a day's truck testing, each and every one still storming along in the accustomed manner.

The TL12 engine and nine-speed Fuller gearbox, backed up by the Albion 11tonne hub reduction axle, was one of the most effective drivelines of the mid-1970s, and none of the Continentals could match it for economic effect, even if it was a bit noisy and harsh. Marathons had a reputation for having one of the lowest running cost profiles in the business.

Sadly it was five long years before the Leyland Vehicles Group, as it was by then called, did anything about updating it, or even doing anything about the accepted minor faults.

CM's Bill Brock tested the Marathon 2 in May 1978, and found it much improved in detail, and still an impressive charger on the road. It was only the second 32tonner ever, to cover CM's first-day test route from Hemel Hempstead to Pathead — over 600km — in under eight hours actual running time, and that despite a fault in the gearbox's range-shift system. It was also remarkably economical, despite the fast journey time, with a test consumption figure better than 7mpg overall. In 1978 that was a very good result.

SUPERB HANDLING

The ride was still a bit harsh, Brock reported together with several thousand fleet drivers. Poor aerodynamics meant fouled mirrors in wet weather, but basic visibility was good from that high driving position. Despite the hard ride, the handling was superb. What few people knew at the time was that the Marathon 2 was a production test bed for a lot of the systems to be installed in the T42 project which became the T45 Roadtrain two years later. The whole drive-train was virtually identical, as were some of the maintenance and access parameters.

By that time the Leyland Vehicles Group had recovered from the profligate days when all truck profits were shipped down the road to support insupportable motor cars. That was the stated policy of the National Enterprise Board when it took over management of the group in 1976.

It was all too late, however. The damage had been done. The Marathon was sound if not visually pretty. The T45s were visually attractive as well as engineeringly competent. But dealer and customer confidence had been lost. The huge debt legacy of abortive motor car programmes was the biggest millstone. The deep recession of the early 1980s prevented recovery at a time when the product might just have pulled the company through.

It was, like so many other industrial stories, a case of what might have been. by Pat Kennett