• If you visit the Motor Show in Birmingham over

Page 39

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

the next 10 days, one new British chassis you are unlikely to see is the Foden 2000 Series.

The 17-tonne rigid was introduced by Foden in March following protracted denials of any plans to extend its production into the lower weight sectors. Until then Foden's range had been restricted to tractive units and multi-wheeled rigid chassis.

The company's decision to withdraw from Britain's premier commercial vehicle exhibition was made several years ago. Like some of the larger names, who have since followed its lead, Foden took the view that it could make better use of its time and money elsewhere, and the 2000 Series may well be another result of this philosophy.

On the face of it Foden's engineers, uninhibited by the design constraints of any previous models in this class, had the chance to produce something radical. In reality there was no option but to conform by using major proprietary components: in-house contributions comprise mainly the chassis and cab.

Wheelbases from 4.0 to 6.2m provide for a wide variety of body sizes and applications; a 7.1-tonne front axle gives a loading tolerance of 60()kg. Flanges are ready drilled to suit, but while additional holes may be introduced into the web in line with manufacturers' recommendations, welding of brackets or other equipment on to Foden's hightensile steel frame is a non-starter.

The composite cab construction, employing GRP panels mounted on a steel frame with aluminium doors, is a wellproven system. As many operators of the larger Foden models can confirm Foden's cabs are light, strong, fire resistant and rust proof. They are a welcome arrival on the 17-tonne scene, and if they are slightly smaller than some existing cabs, that contributes to their low weight and aerodymanic qualities.

• DRIVELINE

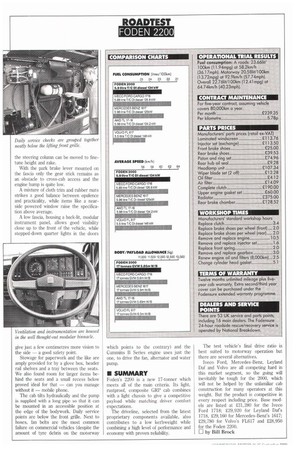

The driveline specification takes advantage of some of the latest developments from Cummins, Eaton, ZF and Rockwell. Our 2200 test vehicle is powered by the Cummins charge-cooled 6B1'A developing 134kW (180hp) at 2,500rpm. In practice there is little point in going over 1,900rpm; the extra 600rpm produces only an extra 7kW (9hp), and at a point where the specific fuel curve is racing skyward. The most economical operating range is between maximum torque at 1,500rpm, and 1,900rpm. As an option Foden will soon fit the Perkins Phaser engine, but that will have to wait for a future test.

The specification sheet includes a choice of three gearboxes. Two six-speed synchromesh units; Eaton's 4106 and ZF's 6S66. Our 2200 came with the third option, a nine-speed Eaton 6109 rangechange unit. Its aluminium casing fits in well with the concept of a lightweight construction and the nine ratios combine an adequate restart capability with an even spread of cogs up to maximum speed to cope with all types of terrain while allowing tight control over engine revs.

Matched to the Cummins B Series engine the 6109 is working well below its full potential — it is rated to accept a direct torque input of up to 912Nm (673Ibft). The double-H gate provides for simple, clean selection of each ratio with crawler and reverse reached only after negotiating a firm detent. While not a gearbox to be rushed, it is easy to use.

A Rockwell R144 drive axle, equipped with a high (4.11:1) final ratio, gives a geared speed of 116km/h (73mph), so at motorway speeds the engine pulls strongly at the top end of its most economical speed band.

II PERFORMANCE

At 80km/11 (50mph) on dual carriageways there is still torque in hand but at 64km/h (40mph) in top gear engine revs fall back to a point where torque backup is beginning to drop away fast. Unless the road is flat or slightly downhill seventh gear is needed to supply the required pulling power, and it is likely that economy will be better as well.

It comes as no surprise that the 17tonner performs at its best over the motorway section, returning a creditable fuel consumption of 20.581it/100km (13.72mpg) after starting from cold, with a high averge speed of 92.9km/h (57.7mph). Over the initial couple of inclines road speed dropped off slightly, but as the engine started to warm to its task it went from strength to strength.

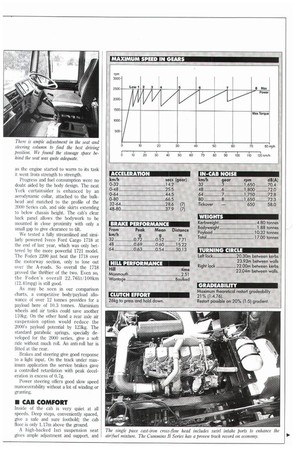

Progress and fuel consumption were no doubt aided by the body design. The neat York curtainsider is enhanced by an aerodynamic collar, attached to the bulkhead and matched to the profile of the 2000 Series cab, and side skirts extending to below chassis height. The cab's clear back panel allows the bodywork to be mounted in close proximity with only a small gap to give clearance to tilt.

We tested a fully streamlined and similarly powered Iveco Ford Cargo 1718 at the end of last year, which was only bettered by the more powerful 1721 model. The Foden 2200 just beat the 1718 over the motorway section, only to lose out over the A-roads. So overall the 1718 proved the thriftier of the two. Even so, the Foden's overall 22.761it/100km (12.41mpg) is still good.

As may be seen in our comparison charts, a competitive body/payload allowance of over 12 tonnes provides for a payload here of 10.3 tonnes. Aluminium wheels and air tanks could save another 110kg. On the other hand a rear axle air suspension option would reduce the 2000's payload potential by 123kg. The standard parabolic springs, specially developed for the 2000 series, give a soft ride without much roll. An anti-roll bar is fitted at the rear.

Brakes and steering give good response to a light input. On the track under maximum application the set-vice brakes gave a controlled retardation with peak deceleration in excess of 0.7g.

Power steering offers good slow speed manoeuvrability without a lot of winding or gruntin.

• CAB COMFORT

Inside of the cab is very quiet at all speeds. Deep steps, conveniently spaced, give a safe and sure foothold; the cab floor is only 1.17m above the ground.

A high-backed Isri suspension seat gives ample adjustment and support, and the steering column can be moved to finetune height and rake.

With the park brake lever mounted on the fascia only the gear stick remains as an obstacle to cross-cab access and the engine hump is quite low.

A mixture of cloth trim and rubber mats strikes a good balance between opulence and practicality, while items like a nearside powered window raise the specification above average.

A low fascia, housing a back-lit, modular instrument panel, allows good visibility close up to the front of the vehicle, while stepped-down quarter lights in the doors give just a few centimetres more vision to the side a good safety point.

Stowage for paperwork and the like are amply provided for by a glove box, header rail shelves and a tray between the seats. We also found room for larger items behind the seats and a small recess below proved ideal for that can you manage without it mobile phone.

The cab tilts hydraulically and the pump is supplied with a long pipe so that it can be mounted in an accessible position at the edge of the bodywork. Daily service points are below the front grille. Next to hoses, fan belts are the most common failure on commercial vehicles (despite the amount of tyre debris on the motorway which points to the contrary) and the Cummins B Series engine uses just the one, to drive the fan, alternator and water pump.

• SUMMARY

Foden's 2200 is a new 17-tonner which meets all of the main criteria. Its light, rustproof, composite GRP cab combines with a light chassis to give a competitive payload while matching driver comfort expectations.

The driveline, selected from the latest proprietary components available, also contributes to a low kerbweight while combining a high level of performance and economy with proven reliability. The test vehicle's final drive ratio is best suited to motorway operation but there are several alternatives.

Iveco Ford, Mercedes-Benz, Leyland Daf and Volvo are all competing hard in this market segment, so the going will inevitably be tough for the 2000, which will not be helped by the unfamiliar cab construction for many operators at this weight. But the product is competitive in every respect including price. Base models are listed at 231,280 for the Iveco Ford 1718; £29,920 for Leyland Dafs 1718, £29,160 for Mercedes-Benz's 1617; £29,780 for Volvo's FL617 and 228,950 for the Foden 2200.

El by Bill Brock