TANK DIVISI

Page 156

If you've noticed an error in this article please click here to report it so we can fix it.

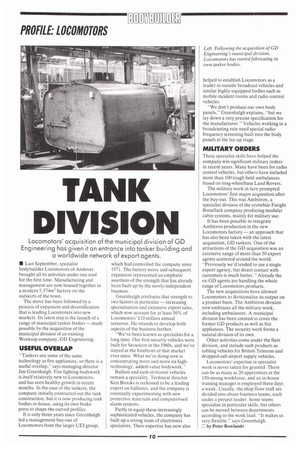

Locomotors' acquisition of the municipal division of GD Engineering has given it an entrance into tanker building and a worldwide network of export agents.

• Last September, specialist bodybuilder Locomotors of Andover brought all its activities under one roof for the first time. Manufacturing and management are now housed together in a modern 5,574m2 factory on the outskirts of the town.

The move has been followed by a process of expansion and diversification that is leading Locomoters into new markets. Its latest step is the launch of a range of municipal tanker bodies— made possible by the acquisition of the municipal division of an existing Worksop company, GD Engineering.

USEFUL OVERLAP

"Tankers use some of the same technology as fire appliances, so there is a useful overlap," says managing director Jim Greenhalgh. Fire fighting bodywork is itself relatively new to Locomotors, and has seen healthy growth in recent months. In the case of the tankers, the company initially contracted out the tank construction, but it is now producing tank bodies in-house, using its own brake press to shape the curved profiles.

It is only three years since Greenhalgh led a management buy-out of Locomotors from the larger UEI group, which had controlled the company since 1971. The factory move and subsequent expansion represented an emphatic assertion of the strength that has already been built up by the newly-independent business.

Greenhalgh attributes that strength to two factors in particular— increasing specialisation and extensive export sales, which now account for at least 30% of Locomotors' £10 million annual turnover. He intends to develop both aspects of the business further.

"We've been known as specialists for a long time. Our first security vehicles were built for Securicor in the 1960s, and we've stayed at the forefront of that market ever since. What we're doing now is concentrating more and more on hightechnology, added-value bodywork."

Bullion and cash-in-transit vehicles remain a speciality. Technical director Ken Brooks is reckoned to be a leading expert on ballistics, and the company is constantly experimenting with new protective materials and computerised alarm systems.

Partly to equip these increasingly sophisticated vehicles, the company has built up a strong team of electronics specialists. Their expertise has now also helped to establish Locomotors as a leader in outside broadcast vehicles and similar highly-equipped bodies such as mobile incident rooms and radio control vehicles.

"We don't produce our own body panels," Greenhalgh explains, "but we lay down a very precise specification for the manufacturer." Vehicles working in a broadcasting role need special radio frequency screening built into the body panels at the lay-up stage.

MILITARY ORDERS

These specialist skills have helped the company win significant military orders in recent years. Many have been for radio control vehicles, but others have included more than 100 tough field ambulances based on long-wheelbase Land Rovers.

The military work in turn prompted Locomotors' first major acquisition after the buy-out. This was Ambitron, a specialist division of the erstwhile Freight Bonallack company producing modular cabin systems, mainly for military use.

It has been possible to integrate Ambitron production in the new Locomotors factory — an approach that has also been taken with the latest acquisition, GD tankers. One of the attractions of the GD acquisition was an extensive range of more than 50 export agents scattered around the world. "Previously we'd tended to use a single export agency, but direct contact with customers is much better." Already the ex-GD agents are handling the whole range of Locomotors products.

The new acquisitions have allowed Locomotors to divisionalise its output on a product basis. The Ambitron division now embraces all the military work, including ambulances. A municipal division has been created to cover the former GD products as well as fire appliances. The security work forms a natural division of its own.

Other activities come under the fleet division, and include such products as cabling vehicles for British Telecom and dropped-cab airport supply vehicles.

Locomotors' expertise in specialist work is never taken for granted. There can be as many as 20 apprentices in the 150-strong workforce, and an in-house training manager is employed three days a week. Usually, the shop floor staff are divided into about fourteen teams, each under a project leader. Some teams specialise in particular skills, but others can be moved between departments according to the work load. "It makes us very flexible," says Greenhalgh.

by Peter Rowlands