Leyland aids Scania's Danish breakthrough

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

tance and improved life, and Scania's limited capacity Katrineholm body plant only builds steel-framed vehicles, HT has again gone to its long-standing specialist supplier Leyland-DAB in Silkeborg for production of the new fleet additions.

The wholly owned Leyland subsidiary is thus in the intriguing position of boosting the breakthrough of Scania into the Danish bus market. The autonomy which the Silkeborg company retains in marketing decisions is, however, also underlined by the Volvo-based interuban units currently being built there for Danish State railways road services.

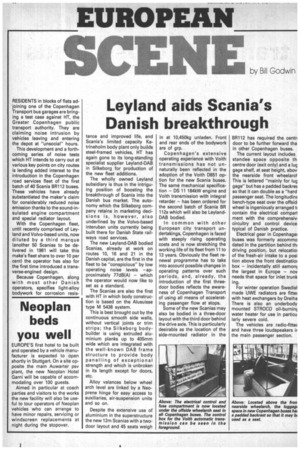

The new Leyland-DAB bodied Scanias, already at work on routes 10, 16 and 21 in the Danish capital, are the first in the fleet to be "conspicious" by low operating noise levels —approximately 77dB(A) — which the operator would now like to set as a standard.

The Scanias are also the first with HT in which body construction is based on the Alusuisse type M 5438 system.

This is best brought out by the continuous smooth side walls, without vertical joints or trim strips; the Silkeborg bodybuilder is using extruded aluminium planks up to 405mm wide which are integrated with the well-known DAB frame structure to provide body panelling of exceptional strength and which is unbroken in its length except for doors, etc.

Alloy valances below wheel arch level are linked by a Neoprene hinge for easy access to auxiliaries, air-suspension units and so on.

Despite the extensive use of aluminium in the superstructure the new 12m Scanias with a twodoor layout and 45 seats weigh in at 10,450kg unladen. Front and rear ends of the bodywork are of grp.

Copenhagen's extensive operating experience with Voith transmissions has not unnaturally been reflected in the adoption of the Voith D851 option for the new Scania buses. The same mechanical specification — DS 11 184kW engine and Voith transmission with integral retarder — has been ordered for the second batch of Scania BR 112s which will also be LeylandDAB bodied.

In common with other European city transport undertakings, Copenhagen is faced with steeply rising operating costs and is now stretching the working life of its fleet from 11 to 13 years. Obviously the fleet renewal programme has to take into account possible changes in operating patterns over such periods, and, already, the introduction of the first threedoor bodies reflects the awareness of Copenhagen Transport of using all means of accelerating passenger flow at stops.

Some of the new Scanias may also be bodied in a three-door layout with the third door behind the drive axle. This is particularly desirable as the location of the side-mounted radiator in the BR112 has required the centn door to be further forward tha in other Copenhagen buses.

The current layout includes standee space opposite th centre door (exit only) and a lug gage shelf, at seat height, abov the nearside front wheelard This is lettered "mainly for lug gage" but has a padded backres. so that it can double as a "hard passenger seat. The longitudinz bench-type seat over the offsid, wheel is ingeniously arranged ti contain the electrical comparl ment with the comprehensivi circuitry and control device: typical of Danish practice.

Electrical gear in Copenhager buses was formerly accommo dated in the partition behind thi driving position, but relocatior of the fresh-air intake to a posi tion above the front destinatior box — incidentally still aamoni the largest in Europe — nov needs that space for inlet trunk ing.

For winter operation Swedisi made UWE radiators are fitte( with heat exchangers by Dreiha There is also an underbody mounted STROCO water heater for use in particu larly severe cold.

The vehicles are radio-fitte( and have three loudspeakers ir the main passenger section.